Basalt Ecover insulation - a modern universal material for the construction of a durable layer of thermal insulation. Its technical characteristics allow the product to be used in various fields of construction.

Features and nuances of the production of insulation Ecover

Products of the Ecover brand are made by melting raw materials with a mineral base, into which synthetic components are added. The technology of drawing the liquid mass on specialized equipment provides a fibrous structure. Raw materials are prepared in filtration plants that process industrial waste.

Three methods for producing basaltic threads have been developed:

- blowing;

- centrifugal roll;

- centrifugal blow.

The choice of a particular technique is affected by the availability of the required equipment. Technologists control every stage of the production process. All modifications of the insulation pass through such stages of manufacture:

- remelting;

- centrifugation;

- adding special synthetic sealants to the mass;

- pressing the resulting composition.

At the last stage, the canvas is cut into plates and packaged.

Advantages and disadvantages

Thermal insulation Ecover has a number of advantages when comparing this insulation with analogues:

- 50% reduction in thermal losses;

- the material is not susceptible to bacteria, fungi, mold;

- rodents do not spoil the product;

- resistance to ultraviolet;

- good sound absorption;

- environmentally friendly material;

- tends to withstand high-temperature influences;

- does not deform under mechanical and static load;

- long term of use - more than 50 years;

- good hydrophobicity and vapor permeability;

- easy installation.

The main disadvantage of insulation is its high cost.

Specifications

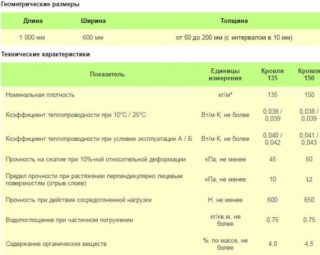

The basis of all the brand's insulation is high-tech stone wool, extracted from rocks. Product Specifications:

The basis of all the brand's insulation is high-tech stone wool, extracted from rocks. Product Specifications:

- density - from 30 to 60 kg / m3 (depends on the type of mineral wool);

- thermal conductivity - 0.035–0.041 W / m * K;

- water absorption - not higher than 1.5% kg / m2;

- sound absorption - up to 0.85;

- fiber melting point - 1000 °;

- the content of organic segments is less than 4%.

Ecover mineral wool is produced in the form of plates measuring 1.0 * 0.6 m, with a thickness ranging from 30–250 mm. Thanks to these parameters, the application of thermal insulation has been expanded. The choice of brand of product depends on the required thickness of the insulation.

Use of insulation Ecover

The scope of thermal insulation is extensive. The material is suitable for frequent construction and repair, it is used in industry. Recommended product for insulation:

- loggias, balconies;

- walls and internal partitions;

- roofing, attic floors;

- facades;

- sexes;

- communication systems (heating, ventilation and water supply).

The main objective of the product is the thermal insulation of rooms, protecting them from extraneous noise. The density of the plates and the additives used are the parameters by which the products are classified.

For civil engineering

There are several material modifications in this category:

- For general construction purposes, an Ecover insulation standard 50 with dimensions of 1000x600x50 mm is used. The product is suitable for warming small-sized cottages, suburban summer houses.

- Ecover Light is suitable for thermal insulation of apartments.It is convenient to protect all rooms with these plates. The coverage area of the material is all kinds of brick, concrete and stone surfaces, artificial materials (aerated concrete). Floors and walls, ceilings are insulated with mineral slabs, they decorate loggias or balconies, foundations and the space under the roof. The material is suitable for insulation of utility rooms adjacent to a residential building: garage, summer kitchen, workshop, bathhouse or boiler room.

- For flooring, the product Ecover Step is used.

- Technical version - Ecover Fire Protection. Products are intended for reliable insulation and resistance to the spread of flame in building or engineering structures (fire doors, gates).

- For insulation of apartments

- For plastering

- For underfloor heating

Facade insulation

The following grades of plates are suitable for facades:

- Facade decor;

- Optima decor;

- Sandwich and Sandwich K.

- Light and Light Station wagon.

It is convenient for any of these versions to sheathe the facades of one-story and high-rise buildings. All of them are widely used in the construction of civil or industrial facilities. The good density and rigidity of mineral slabs allows the use of materials of these modifications for waterproofing basement or basement.

The minimum thermal conductivity and high vapor permeability provide facade heaters with demand from builders. Additional advantages: easy installation, reasonable cost and fire safety.

Heat and sound insulation for roofs

Roofing models are designed for insulation of roofs of any configuration. For the arrangement of space under the roof, the best product modifications are:

- Acoustic. To create reliable sound insulation, important in a situation with a metal roofing, the manufacturer recommends the installation of this special version of basalt wool. Plates are also mounted on the floor, ceiling, partitions between floors - wherever logs are provided. To eliminate the noise, the required thickness of the product is selected.

- Insulation Ecover standard - a universal material used to create a strong thermal barrier in the room. The product has a high density coefficient (60 kg / m³), excellent thermally insulating characteristics, durability, hydrophobicity, ease of installation, frost resistance and other valuable characteristics. This allowed the slabs of this modification to become popular in the construction of buildings and in situations with the repair of previously operating structures. The material does not contain any components that can irritate human skin.

Minvata for sandwich production

The industrial line Sandwich is designed for thermal insulation of the same name panels. Ecover Sandwich K and Ecover Sandwich C - modifications with a narrow specialization in use. A high density index (100–140 kg / cubic meter), low thermal conductivity (0.041 W / mK (λA), compressive strength (65–100 kPa) and fire safety (class of flammability of NG) are some of the worthy characteristics of the material.