Attic is a room from which you can make an area suitable for relaxation at any time of the year. To ensure the comfort of your stay, you can provide internal insulation of the attic with mineral wool. Wall, roof and floor are insulated with this material. You can cover the house with insulation yourself, following the installation instructions.

The need for thermal insulation

Usually the attic in the country is arranged from the attic. Such premises are not suitable for living because of the large number of gaps through which cold air penetrates into the house and warm air comes out. To reduce heat loss, special insulating materials are used that are placed on ceilings, walls and floors. When using high-quality heaters, which include mineral wool, you can get a room with a comfortable temperature regime at any time of the year.

Attic thermal insulation requirements

In addition to improving the temperature regime in the room, insulation performs other tasks: protection from moisture and draft, from the formation of condensate and, as a result, mold and fungi.

Thermal insulation can protect the room from insects. To solve these problems, additional vapor barrier materials and waterproofing membranes are used.

The thickness of the insulation of the mineral wool of the attic floor depends on the number of layers. The thickness of one layer of mineral wool is 150-200 square meters.

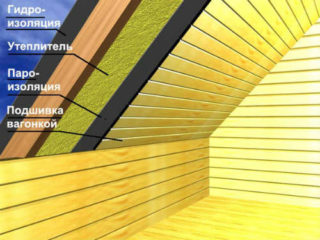

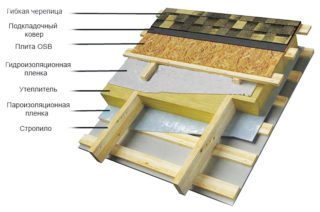

When working with the material, you need to decide which layer is needed when warming the mineral wool of the attic. The insulation scheme includes the following components:

- Waterproofing. Passes steam, but does not pass moisture.

- Insulation with low thermal conductivity. Penofol, penoplex, mineral wool and other materials are used.

- Vapor barrier. It is also an obligatory layer for protection against water.

The main requirements for thermal insulation are environmental friendliness, resistance to fire and incombustibility, minimum thickness. Mineral wool corresponds to all these characteristics. Its heat-insulating properties have low thermal conductivity, which is 0.036 W / micron, and the material also has a long service life - from 50 years.

Pros and cons of mineral wool

Minvata is considered the best insulation that can be used for attics. Its benefits include:

Minvata is considered the best insulation that can be used for attics. Its benefits include:

- high degree of frost protection;

- high level of sound insulation;

- immunity to fire;

- does not deform when heated and cooled;

- resistant to decay and the formation of harmful fungi and bacteria;

- resistance to chemicals;

- profitability;

- manufacturability;

- the opportunity to buy material in any hardware store.

The negative features include the ability to absorb water. Liquid can lead to poor thermal insulation properties.

There is also a strict need for safety precautions when working with mineral wool, unlike the installation of foam and other materials. It is important to prevent particles of mineral wool from getting on human skin. To do this, the master must work in protective tight gloves, goggles and a respirator. There should not be exposed areas of the body.

Do-it-yourself inside attic insulation technology

To keep the room warm, you need to insulate the floors, walls, roof.

Insulation of walls from the inside

All work consists in arranging the frame from the beam, into which the insulation material will be further laid. Then, a decorative design will be attached to this frame.

The algorithm for warming the wooden wall of the attic of the mineral wool house:

- Wall preparation. They should be smooth, without moss, mold and other fungi. All cracks should be sealed with sealant.

- Waterproofing should be laid over the entire surface of the walls. It is fixed with the help of a construction stapler.

- A vertical frame is made from the bars. Its step should be equal to the thickness of the plates or rolls of insulation. The gap between the timber and mineral wool should be minimal. Mounting is carried out on dowels.

- Mineral wool is placed in the cells obtained.

- The final step is to fix the vapor barrier film. It is fixed without sagging on the stapler.

After the steps described, you can proceed to wall cladding with different materials - lining, drywall, OSB. They are placed on a wooden frame.

Floor insulation

Typically, the floor is in the form of a wooden log structure. Insulation is also carried out using mineral wool.

Installation is as follows:

- Floor preparation. Removing the old coating.

- Checking lags for damage and defects.

- Fastening on the surface of the lags of the vapor barrier layer. Fixing is done on a construction stapler.

- Laying mineral wool between the lags.

- Fastening the second layer of vapor barrier material.

The last step is lining the front.

Roof insulation

The insulation for roof insulation is fixed between the rafter system, and then sheathed with cladding.

Step-by-step instructions for laying insulation on the roof:

- On the surface, it is necessary to roll out and fix the waterproofing with a stapler. The film should be overlapped by 5-10 cm. The joints can be sealed with reinforced tape.

- Laying mineral wool between the rafters. If the dimensions of the reinforcing material are selected correctly, it is not necessary to fix it. The density and weight of mineral wool makes it possible to fasten between rafters without additional clamps.

- Laying a vapor barrier membrane.

- Arrangement of a frame for drywall on the rafters.

Next, the final finish of the roof. It must be sewn with plasterboard plates.