Despite the widespread use of modern heating boilers, traditional stoves do not lose their relevance. However, their effectiveness sometimes leaves much to be desired. Installing a heat exchanger for the furnace will make it truly universal. Not only the surrounding air will warm up, but also the coolant circulating through the system. Buying a new full boiler is not always advisable. Especially if the zealous owner has a desire, opportunity and guide to action.

Principle of operation and function of the heat exchanger

A liquid heat exchange device is a tank, part of a furnace structure, equipped to be connected to a pipeline. The tank is heated in contact with the combustion products of the fuel, and transfers this energy to water. Water moving through the system gives off heat to heating devices - radiators, from which air is heated convectively. Heating of the tank can be direct or indirect, and the circulation of the coolant can be natural or forced.

Coolant

Instead of water, ethylene glycol, propylene glycol, alcohol or oil based antifreezes are often used. Their main advantage is the low freezing temperature, which is in the range from -30 to -70 ° C. The exact numbers depend on the chemical composition and concentration of the liquid. The use of such chemistry provides several advantages:

- protection of system elements from damage due to defrosting;

- anticorrosion protection due to appropriate additives;

- the absence of abrasives, salts and other impurities that destroy (clog) the pipeline or fittings.

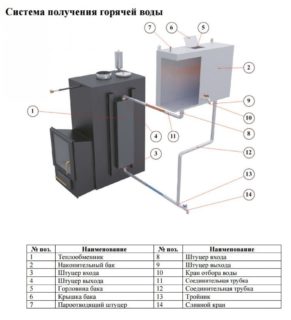

Some heat exchangers, for example, for a bath, serve not only heating appliances, but also a shower or a separate tank. Therefore, water is used here. In order to avoid defrosting, the device is designed so that pouring water does not take much time. If the bathhouse or sauna is often heated, and the building envelopes are insulated with high quality, the problem is removed.

Propylene glycol is expensive, alcohol and oil are flammable, and ethylene glycol is a highly toxic coolant.

Heat exchanger functions

The function of the heat exchange tank, as part of the furnace structure, is the reception and transfer of heat to the coolant from the combustion products. But as an element of a wider system (heating, water supply), it solves several problems.

The function of the heat exchange tank, as part of the furnace structure, is the reception and transfer of heat to the coolant from the combustion products. But as an element of a wider system (heating, water supply), it solves several problems.

- Distribute heat evenly and economically over heated rooms.

- Provide a house (cottage, cottage, bathhouse, apartment, etc.) with hot water.

- Accumulate thermal energy for use with an idle stove.

A heat accumulator connected to a heat exchanger for a wood burning stove stores energy due to the heat capacity of the storage agent. Therefore, it can be made by isolating any container. A barrel doused with mounting foam and partially filled with rubble or sand is already a heat accumulator. If you equip it with four pipes and connect it correctly, the unit will become a functional element of the system.

Cooling 1 ° C, the water heats 1 m3 of still ambient air at 4 ° C. The successful use of water heat accumulators is associated with this.

Types of heat exchangers

A simple device can be effective in many ways - depending on the type. The classification is carried out according to several criteria. Different models of factory or artisanal heat exchangers, for example, in a bath, differ:

- construction

- place of installation

- material.

These factors affect each other and the features of the heat exchange unit as a whole: its cost, efficiency, productivity, system volume, installation complexity, etc.

Design

Design differences largely depend on the purpose of the product. For example, heating wash water involves a substantial amount and intense heat transfer. And use only for heating requires a gradual transfer of heat to the coolant.

- The coil is a pipe bent at different angles. It warms up quickly, but often does not have enough volume. Suitable for installation in a wood firebox, behind a firebox, in a stove, in a chimney (if the coil is spiral).

- The register is an analogue of a pipe radiator, perhaps the most popular, universal, energy-efficient. As a rule, these are several large-diameter pipes connected by thin pipes. The choice of a specific form and installation location is limited by the author’s imagination, as well as the general scheme.

- Diplomat - one or more interconnected containers with nozzles. This is a common model, easy to assemble and install. A bath furnace with a heat exchanger of this type will provide heat, heat, hot water. Disadvantages - a significant amount reduces the heating rate, limits the choice of place for installation. The primitive form does not contribute to full heat transfer, interfering with the heating of parts of the stove itself. Therefore, it is suitable only for installation inside the heater (if we are talking about the bath), for it or for the furnace.

- Water jacket - a casing installed on the parts of the heat generator heated from the inside. Often this is a cylinder with nozzles, worn on the chimney. It is difficult for handicraft assembly, prone to leaks, but it does not require disassembling the stove for installation and is quite effective.

- Water jacket

- Diplomat

- Register

The choice of model is usually associated not so much with efficiency and price as with the complexity of the installation. For example, some modifications of water "shirts", "coils" and "diplomats" are mounted without disassembling the furnace. The maximum is the modernization of a part of the pipe or the replacement of a cast-iron plate (for cooking) with a "diplomat".

Heat transfer registers are generally preferable to other devices. However, they are installed only during the construction of a new stove or a serious alteration of the old one.

Material

When designing a stove or fireplace with a heat exchanger, an engineer (or stove) takes into account the parameters of the materials. Necessary properties - fire resistance, elasticity, corrosion resistance, heat capacity, thermal conductivity. Only metals possess these characteristics.

- Steel is perfect in all respects except corrosion resistance. However, if the coolant is always filled, it will not rust.

- Stainless steel has no drawbacks, except for the high price and complexity of welding. Galvanized steel is almost never used due to toxic emissions associated with high temperatures.

- Cast iron, the disadvantages of which are the complexity of welding and the high probability of cracking (due to sudden changes in temperature during uneven heating).

- Copper, which is good for everyone, except for the high price and soldering of the parts. The solder “does not hold” strong heat if water is drained, so the use of copper is limited.

The choice is usually related to the availability or availability of material. Often there are bath stoves with a cast-iron heat exchanger, which is a modified battery. The refinement consists in boiling the joints of the sections and plugs in the extra holes. Thereby, a heat transfer register is obtained having all the necessary properties. Its disadvantage is the cumbersomeness that limits the choice of place.

DIY making

Making a decision on self-production, as a rule, indicates the presence of some tool and skills to work with it. Ideally, you need a full-fledged workshop with a vise, welding (two types), a workbench, an anvil, etc.If the equipment leaves much to be desired, the option of assembling the simplest modification is possible - a copper spiral coil.

Pluses of this option:

- Copper is relatively easy to bend, solder.

- The coil does not contain compounds that are exposed to extreme heat.

- The spiral form is simple, universal, and complex equipment is not needed to give it.

- The installation of such a heat exchange device does not require a major modernization of the furnace design.

A bath stove with such a heat exchanger will cope with everything that can be expected from it: it will provide 2–3 heating radiators, it will heat water in a small tank. For the microclimate in the steam room, nevertheless, the heater answers.

Expendable materials

Of the special tools for working with copper, only a gas burner is needed. A professional will need a pipe cutter, a chamfer, a metal brush of the right size. However, all this is replaced by a grinder, a file (rasp), a soft abrasive sponge. Supplies will also need a minimum:

- annealed copper pipe in d32 bay, length 3.5 - 4.5 m (depending on d chimney);

- transitional water sockets (thread-soldering) d32 * 1.25 ”- 2 pcs;

- ordinary low-temperature and hard copper solder for medium-temperature brazing (650 - 750 ° C);

- flux paste;

- soft abrasive sponge;

- propane-butane gas for medium temperature brazing - 1 cylinder (0.5 L);

- washed sifted fine sand - 5 - 6 kg;

- pipeline, taps, "Mayevsky" valves, radiators.

A “pipe bender” is required - an even round log. With its help, the heat exchanger for the bath stove will receive the shape of a spiral coil. The length of the log is at least 1 m, and the diameter is equal to the dimensions of the chimney at the outlet of the stove. As a rule, the parameter depends on the size of the furnace and is not less than 10 cm.

The log should be rigidly fixed, fixing it with powerful screws / dowels between two trees or walls.

Build algorithm

The most difficult part of the assembly is the spiraling shape. To do this, the pipe will have to be bent using a rigidly installed log. Unburned copper cannot be bent, so you need to buy exactly the one in the bays. The easiest way to install a “coil” heat exchanger in a brick oven (for heating) is to install it in a chimney. Algorithm of actions:

- Securely plug one end of the pipe with, for example, a sealed factory plug.

- Fill the pipe with sand, spilling it with water, tapping it with a hammer, sealing it with a “ramrod”. It may be a plastic pipe or a drowned rubber hose.

- When the pipe is full, seal the filler as much as possible, then plug the other end. Try not to “flatten” the sand.

- Screw a U-shaped or round clamp to the log that will hold the pipe tightly. The base “P” is perpendicular to the pipe bender closer to the end, and the circumferential arrangement does not play a role.

- Insert the end of the bay into the clamp, begin, slowly, wind the pipe onto the log.

- If somewhere appeared a hall, it means that in this place the sand is not tight enough. It is advisable to start all over again, but, theoretically, you can try to tap the hall with a hammer.

- If the chimney d is 150, and the bay length is 4.5, you should get 8 - 9 turns of a spiral (height not more than 35 - 40 cm), as well as two “tails” of 30 - 40 cm.

- Cut off the plugs, clean the sand, rinse the spiral.

- Solder transitional water sockets to the ends of the spiral.

- Remove the cover covering the heater, or remove the slide gate (remove part of the chimney).

- Put the “coil” on the pipe as close to the stove as possible.

- Reassemble the chimney, taking into account the necessary sealants, windings (if they were).

Now you can install and connect the remaining elements of the heating system, including the open expansion tank of the samovar type, piping, taps, radiators, air valves. To improve natural circulation, the diameter of the pipeline should not be much smaller than the size of the coil.Ideally, it will also be copper, of the same diameter.

The likely difficulty is a decrease in draft due to unintended heat removal from the chimney. The solution is to increase the length of the chimney.

Heat exchange design options

The installation of a heat exchange device of any kind involves a considerable amount of work, especially if its effectiveness is of serious importance. For example, the simplest spiral in the chimney can warm up slightly, and there can be no circulation without a pump at all. Then you have to take measures, up to the rejection of such a design. In practice, a single heat exchanger for the furnace, installed in different places, gives different efficiency. It is conditionally possible to make such a TOP, starting with the most effective variety:

- cast-iron or steel U-shaped register in the furnace;

- a water shirt around the firebox or at any of its surfaces;

- U-shaped diplomat in a firebox;

- a diplomat directly above or behind the firebox with maximum contact;

- water shirt around the heater;

- register, diplomat or coil in the heater;

- a diplomat or a coil behind a heater;

- water shirt in the chimney.

The chimney coil is conditionally the least effective option. However, the simplicity of the device often eliminates the disadvantages. In addition, efficiency is improved in various ways. Among them - the coil lining with a thermally insulated casing with filling the voids with sand or the installation of the structure directly into the heater.

All names are conditional. For example, such a factory construction is not uncommon when a cubic-shaped container is built above the heater. She can be considered a shirt or a diplomat.

Proper connection

A wood stove or fireplace with any heat exchanger is just part of the system. For its energy-efficient operation, the circulation of the coolant remains a key factor. Even when the use of a pump is clearly necessary (for example, in a large two- or three-story house), natural circulation is an important thing. Thanks to it, the pipes do not burst due to defrosting too quickly, and the water does not boil so easily if the electricity goes out. To improve circulation, it is advisable to adhere to the following rules:

A wood stove or fireplace with any heat exchanger is just part of the system. For its energy-efficient operation, the circulation of the coolant remains a key factor. Even when the use of a pump is clearly necessary (for example, in a large two- or three-story house), natural circulation is an important thing. Thanks to it, the pipes do not burst due to defrosting too quickly, and the water does not boil so easily if the electricity goes out. To improve circulation, it is advisable to adhere to the following rules:

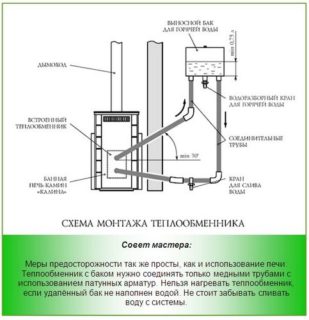

- the higher the run of the heat exchanger nozzles in height, the better;

- the expansion tank is placed as high as possible, next to the stove;

- a pipe goes to the tank from the upper pipe;

- the pipe from the expansion tank goes to the lower entrance of the radiator;

- all horizontal sections are made at an angle (at least 3 mm per 1 m);

- radiator outlet only from the opposite side or diagonally.

Another important point is the cross-country ability of the pipeline. The higher it is, the better. Therefore, you should not narrow the diameter, build in excess knees, fittings, and also use rusty inside or plastic pipes.

The heat exchanger is installed at the stage of assembly of the furnace. If we are talking about an old design, no need to be lazy to disassemble it. In this case, it will be possible to install the most efficient device to where it is required. In passing, a detailed inspection of the masonry, as well as other details, will be carried out. Defects and defects will be eliminated.