The choice of thermal insulation materials in the modern market is huge. Manufacturers produce models that are different in structure, density, soundproofing characteristics and moisture resistance. Consumers need to know the thermal conductivity of heaters and selection criteria. A detailed comparison of all types will help you find the ideal building material.

The concept of thermal conductivity

Thermal conductivity is understood as the transfer of heat energy from an object to an object until the moment of thermal equilibrium, i.e. temperature equalization. In relation to a private house, the speed of the process is important - the longer the alignment takes place, the less the structure cools down.

In numerical form, the phenomenon is expressed in terms of the thermal conductivity coefficient. The indicator clearly expresses the passage of heat over a certain time through a surface unit. The larger the value, the faster thermal energy flows out.

The heat transfer of various materials is indicated in the manufacturer's specifications on the packaging.

Thermal Conductivity Factors

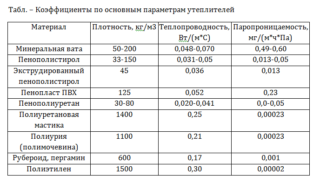

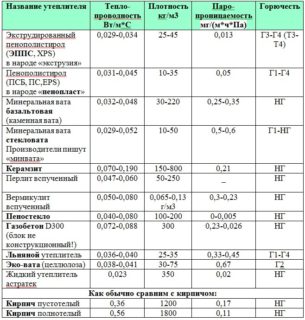

Thermal conductivity depends on the density and thickness of the heat insulation, so it is important to consider it when buying. Density is the mass of one cubic meter of materials that are classified by this criterion as very light, light, medium and hard. Light porous products are used to cover internal walls, load-bearing partitions, dense - for external work.

Modifications with a lower density are lighter in weight, but have better thermal conductivity. A comparison of insulation by density is presented in the table.

| Material | Density indicator, kg / m3 |

| Minvata | 50-200 |

| Extruded Styrofoam | 33-150 |

| Polyurethane foam | 30-80 |

| Polyurethane Mastic | 1400 |

| Ruberoid | 600 |

| Polyethylene | 1500 |

The higher the density, the lower the vapor barrier level.

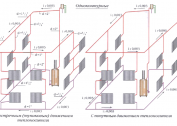

The thickness of the material also affects the degree of heat transfer. If it is excessive, the natural ventilation of the rooms is disrupted. Small thicknesses cause cold bridges and condensation on the surface. As a result, the wall is covered with mold and fungus. Compare the thickness parameters of the materials in the table.

| Material | Thickness mm |

| Penoplex | 20 |

| Minvata | 38 |

| Cellular concrete | 270 |

| Brickwork | 370 |

When choosing a thickness, it is worth considering the climate of the area, the material of construction.

Characteristics of different materials

Before considering the table of thermal conductivity of heaters it makes sense to familiarize yourself with a brief overview. The information will help developers understand the specifics of the material and its purpose.

Styrofoam

Plate material made by foaming polystyrene. It is distinguished by the convenience of cutting and installation, low thermal conductivity - in comparison with other insulators, foam is lighter. Product advantages - low cost, resistance to wet environments. Cons of polystyrene foam - fragility, quick flammability. For this reason, slabs with a thickness of 20-150 mm are used for thermal insulation of lightweight external structures - facades for plastering, walls of socles and basements.

When burning foam, toxic substances are released.

Extruded Styrofoam

Extruded polystyrene foam is resistant to wet environments. The material is easy to cut, does not burn, is easy to lay and transport.In addition to low thermal conductivity, plates have high density and compressive strength. Extruded polystyrene foam of the Technoplex and Penoplex brands is popular among Russian developers. It is used for thermal insulation of the blind area and strip foundation.

Mineral wool

The coefficient of thermal conductivity of mineral wool is 0.048 W / (m * C), which is more than foam. The material is made on the basis of rocks, slag or dolomite in the form of plates and rolls with different stiffness indices. For the insulation of vertical surfaces, it is allowed to use rigid and semi-rigid products. Horizontal structures are better insulated with light miniplates.

Despite the optimal thermal conductivity index, mineral wool has little resistance to a humid environment. Plates are not suitable for insulation of basements, steam rooms, dressing rooms.

The use of mineral wool with low thermal conductivity is allowed only in the presence of vapor barrier and waterproofing layers.

Basalt wool

The basis for insulation is the basaltic type of rock, which swells when heated to a state of fibers. Non-toxic binders are also added in the manufacture. In the Russian market, products of the Rockwool brand, on the example of which we can consider the features of insulation:

- not subject to fire;

- differs in a good indicator of heat and sound insulation;

- lack of caking and compaction during operation;

- environmentally friendly building material.

The thermal conductivity parameters allow the use of stone wool for outdoor and indoor use.

Glass wool

Glass wool insulation is made from borax, limestone, soda, sifted dolomite and sand. To save on production, glass cullet is used, which does not violate the properties of the material. The advantages of glass wool include high rates of heat and sound insulation, environmental friendliness and low cost. Cons more:

- Hygroscopicity - absorbs water, as a result of which it loses warming characteristics. To prevent decay and destruction of the structure, they are placed between the vapor barrier layers.

- Installation inconvenience - fibers with increased fragility disintegrate, can cause burning and itching of the skin.

- Short-term operation - after 10 years, shrinkage occurs.

- Inability to use for warming wet rooms.

When working with glass wool, it is necessary to protect the skin of the hands with gloves, the face with glasses or a mask.

Foamed polyethylene

The rolled polyethylene with a porous structure has an additional reflective layer of foil. Advantages of Isolon and Penofol:

- small thickness - from 2 to 10 mm, which is 10 times less than conventional insulators;

- the ability to save up to 97% of usable heat;

- resistance to moisture;

- minimal thermal conductivity due to pores;

- ecological cleanliness;

- reflective effect due to which thermal energy is accumulated.

Roll insulation is suitable for installation in wet rooms, on balconies and loggias.

Sprayable thermal insulation

If you turn to the table, it can be seen that the sprayed species replace 10 cm of mineral wool. They are available in cylinders, reminiscent of mounting foam and are applied using a special tool. The sprayed insulation can be of different stiffness; foaming agents are also present in the container - polyisocyanate and polyol. By the type of the main component, insulation is:

- PPU. Polyurethane foam with an open cellular structure is durable, heat-efficient. In the presence of closed voids in the composition - it can pass steam.

- Penoizolnaya.The urea-formaldehyde-based liquid foam is characterized by vapor permeability and resistance to fire. It is applied by pouring. The optimum solidification temperature is from +15 degrees.

- Liquid ceramics. Ceramic components are melted to a liquid state, then mixed with polymeric substances and pigments. Vacuum cavities are obtained. External insulation provides building protection for 10 years, internal - for 25 years.

- Ecowool. Cellulose is crushed to a state of dust, becomes sticky when water gets into it. The material is suitable for use on wet wall surfaces, but is not used near chimneys, chimneys and stoves.

Sprayed heaters are distinguished by good adhesion to surfaces for which wood, brick or aerated concrete was used.

Table of thermal conductivity coefficients of different materials

Based on a table with the thermal conductivity coefficients of building materials and popular heaters, a comparative analysis can be done. It will provide the selection of the best thermal insulation for the building.

| Material | Thermal conductivity, W / m * K | Thickness mm | Density, kg / m³ | Laying temperature, ° C | Vapor permeability, mg / m² * h * Pa |

| Polyurethane foam | 0,025 | 30 | 40-60 | -100 to +150 | 0,04-0,05 |

| Extruded Styrofoam | 0,03 | 36 | 40-50 | From -50 to +75 | 0,015 |

| Styrofoam | 0,05 | 60 | 40-125 | From -50 to +75 | 0,23 |

| Minvata (plates) | 0,047 | 56 | 35-150 | -60 to +180 | 0,53 |

| Fiberglass (plates) | 0,056 | 67 | 15-100 | From +60 to +480 | 0,053 |

| Basalt wool (slabs) | 0,037 | 80 | 30-190 | From -190 to +700 | 0,3 |

| Reinforced concrete | 2,04 | 2500 | 0,03 | ||

| Hollow brick | 0,058 | 50 | 1400 | 0,16 | |

| Cross-cut wooden bars | 0,18 | 15 | 40-50 | 0,06 |

For the thickness parameters, an averaged indicator was used.

Other criteria for the selection of insulation

The heat-insulating coating provides a reduction in heat loss by 30-40%, increases the strength of the supporting structures of brick and metal, reduces the noise level and does not take up the useful area of the building. When choosing a heater, in addition to thermal conductivity, other criteria must be taken into account.

Volume weight

This characteristic is related to thermal conductivity and depends on the type of material:

- Mineral-cotton products are characterized by a density of 30-200 kg / m3, therefore they are suitable for all surfaces of the building.

- Foamed polyethylene has a thickness of 8-10 mm. The density without foiling is 25 kg / m3 with a reflective base of about 55 kg / m3.

- Polyfoam differs in specific gravity from 80 to 160 kg / m3, and extruded polystyrene foam - from 28 to 35 kg / m3. The latest material is one of the lightest.

- Semi-liquid sprayed penoizol at a density of 10 kg / m3 requires prior plastering of the surface.

- Foam glass has a density associated with the structure. The foamed version is characterized by a bulk density of 200 to 400 kg / m3. Thermally insulated from cellular glass - from 100 to 200 m3, which makes it possible to use on facade surfaces.

The lower the bulk density, the less material is consumed.

Ability to keep fit

Manufacturers do not indicate the form stability on the package, but you can focus on the Poisson's ratios and friction, resistance to bending and compression. The shape stability is used to judge creasing or changing the parameters of the heat-insulating layer. In case of deformation, there are risks of heat leakage by 40% through cracks and cold bridges.

The shape stability of building materials depends on the type of insulation:

- Vata (mineral, basalt, eco) when laying between rafters straightens. Due to the hard fibers, deformation is eliminated.

- Foamy species hold their shape at the level of hard stone wool.

The ability of the product to keep its shape is also determined by the characteristics of elasticity.

Vapor permeability

Determines the "breathing" properties of the material - the ability to transmit air and steam. The indicator is important for controlling the indoor microclimate - more mold and mildew are formed in mothballed rooms.Under conditions of constant humidity, the structure may collapse.

Determines the "breathing" properties of the material - the ability to transmit air and steam. The indicator is important for controlling the indoor microclimate - more mold and mildew are formed in mothballed rooms.Under conditions of constant humidity, the structure may collapse.

According to the degree of vapor permeability, two types of insulation are distinguished:

- Foams - products for the production of which the foaming technology is used. Products do not leak condensate at all.

- Wool - thermal insulation based on mineral or organic fiber. Materials may leak condensate.

When installing vapor-permeable watts, a vapor barrier film is additionally laid.

Flammability

The indicator, which are guided in the construction of the ground parts of residential buildings. The classification of toxicity and combustibility is specified in Art. 13 Federal Law No. 123. The following groups are identified in the technical regulations:

The indicator, which are guided in the construction of the ground parts of residential buildings. The classification of toxicity and combustibility is specified in Art. 13 Federal Law No. 123. The following groups are identified in the technical regulations:

- NG - non-combustible: stone and basalt cotton wool.

- G - flammable. Materials of category G1 (polyurethane foam) are characterized by low flammability, and category G4 (expanded polystyrene, including extruded) are highly combustible.

- B - flammable: chipboard, ruberoid.

- D - smoke forming (PVC).

- T - toxic (minimum level - on paper).

The best option for private construction is self-extinguishing materials.

Soundproofing

Characteristics associated with vapor permeability and density. Vats exclude the penetration of extraneous noise in the room, more noise penetrates through the foam.

Dense materials have better sound insulation properties, but laying is complicated by thickness and weight. The best option for independent thermal insulation work will be stone wool with high sound absorption. Similar indicators - for light glass wool or basalt insulation with twisted long thin fibers.

The normal indicator of sound insulation is a density of 50 kg / m3.

Practical application of thermal conductivity

After a theoretical comparison of materials, it is necessary to take into account their division into groups of heat-insulating and structural. Structural raw materials have the highest heat transfer indices, so it is suitable for the construction of ceilings, fences or walls.

Without the use of raw materials with insulation properties, it will be necessary to lay a thick layer of thermal insulation. Turning to the thermal conductivity table, we can determine that the low heat transfer of reinforced concrete structures will only be at a thickness of 6 m. The finished house will be bulky, can subside under the soil, and the construction costs will not pay off even after 50 years.

A sufficient thickness of the thermal insulation layer is 50 cm.

The use of thermal insulation materials reduces the cost of construction activities and reduces overpayments for energy in winter. When buying a heater, it is necessary to take into account the thermal conductivity parameters, the main characteristics, cost and convenience of self-installation.