The design of any heating system begins with the calculation of its main parameters. First of all, this concerns the optimal load on the heat supply. Therefore, before purchasing the necessary equipment, it is necessary to calculate the power of the heating system: boilers, radiators, pumps, batteries.

Why is heating necessary?

The decisive task of performing calculations is to optimize further expenses. The minimum required power of the heating boiler will directly affect the energy consumption. But the savings should be within reason.

The main purpose of heat supply is to maintain a comfortable temperature level in residential premises. This is affected by the rated power of cast-iron radiators, heat losses of the building and the parameters of the boiler.

For the correct selection of equipment should correctly calculate its parameters. This can be done using specialized programs or independently, using certain formulas.

In addition, experts recommend calculating the capacity of the heating boiler and other system components for the following:

- Equipment Cost Planning. The greater the rated power of the boiler or the heat transfer of the battery, the higher their cost. As a result, this will affect the budget of the entire event on the arrangement of heat supply;

- Correct scheduling of the load on the system. The correct calculation of the power of the pump for heating will allow you to find out the maximum and minimum load on the equipment when changing external factors - temperature in the street, in the rooms of the house;

- System upgrade. If there are large heating costs, reducing them is a priority to minimize maintenance. To do this, you need to calculate the power of the heating battery and other components.

Having decided that without calculating the basic data, it is impossible to proceed with the procurement of material and accessories for arranging heat supply, you should choose calculation methods. First, the characteristics of each component are individually recognized - the boiler, the radiator pump. Then their parameters are entered into the heating program and checked again. By the same method, the calculation of heating the greenhouse is done.

The type of energy carrier used affects the calculation of the power of a gas heating boiler. It should be decided in advance which type of gas will be used - main or liquefied.

Determination of heat loss at home

At the first stage, it is necessary to correctly calculate the amount of heat that will go through the exterior walls, windows and doors of the building. The work of the heat supply should compensate for these losses and, based on the data obtained, further calculation of the capacity of the circulation pump for heating, boiler and batteries will be performed.

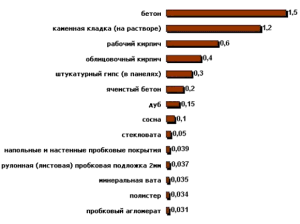

The determining parameter is the heat transfer resistance of walls and window structures. This is the inverse indicator of the thermal conductivity of materials. It is impossible to make a selection of the power of a heating boiler without knowing these values. Therefore, before starting the calculations, you should find out the thickness of the walls and the material from which they are made.

It is recommended that you familiarize yourself with the content of SNiP II-3-79, as well as SNiP 23-02-2003. These documents indicate the standard values of heat transfer resistance for various regions of Russia. Knowing them, you can solve the question of how to calculate the power of a heating radiator.Each material has a specific heat transfer value. Data on the most common for the construction of residential buildings can be taken from standard tables.

But this is not enough to further calculate the power of steel heating radiators. In addition, you will need to find out the thickness of each type of material used for building walls. The ratio of this value to the heat transfer coefficient will be the desired value:

R = D / λ

Where R - heat transfer resistance;D - material thickness;Λ - heat transfer resistance.

In the future, this will be used to calculate the required capacity of the heating boiler. This calculation step is recommended. Only by knowing the actual resistance of the walls can you determine the rated power of the entire heating system.

During the calculation, the wind rose characteristic of each specific region is not taken into account. Data on it affects the calculation only for high-rise buildings.

Features of calculating the power of various heating boilers

For the correct selection of the power of the heating boiler, it is determined in advance with its installation location, the type of heat supply system (open, closed) and the type of fuel used. Additionally, the total area of the house and its volume are taken into account. This data will allow you to make calculations in several ways.

The simplest method to calculate the rated power of heating equipment is to use only the area of the house. For this, a standard ratio is taken that for heating 10 m² of a room it is necessary to spend 1 kW of thermal energy. This method will only work for buildings with good thermal insulation and standard ceiling heights. Its disadvantage is a large error. So, for a house of 150 m², according to the calculation, the power of the heating boiler will need to choose a model of 15 kW.

Additionally, a correction factor is applied, which depends on the location of the building. Then the final formula for calculating the power of a gas heating boiler will look like this:

W = (S / 10) * K

Where W - rated power of the boiler;S - area of the house;K - correction factor.

For the central regions of Russia, K = 0.13; for the northern latitudes of the ego, the value varies from 0.15 to 0.2. When selecting the capacity of the heat supply boiler for the southern regions K = 0.08.

Exact calculations can only be done after a preliminary determination of the heat transfer coefficient of the walls. This technique has been described above. First, we find the temperature difference between the heated air in the street and in the house - Δt. Then it is necessary to determine the heat loss. They are found by the formula:

P = Δt / R

Where R - heat loss at home;Δt - temperature difference;R - heat transfer resistance coefficient.

Further, to calculate the power of a gas heating boiler, it is necessary to multiply the area of the outer walls by heat loss. As an example, take a house with a wall area of 127 m², the coefficient of heat transfer resistance is 0.502. The optimal value of Δt should be 55. In this case, the heat loss per 1 m² will be equal to:

P = 55 / 0.505 = 108 W / m²

Based on this, you can calculate the capacity of the heating boiler:

W = 127 * 108 = 13.7 kW

In the future, the load on the heating system is determined at various values of Δt. It is recommended to choose a model of equipment with a small margin of power - 10-15%. This will expand the heat supply without replacing the boiler and radiators.

For apartments with normal insulation, you can take the ratio of 41 watts of heat per 1 m³ of space in a panel house and 38 watts in a brick building. If the walls were insulated, you will need to do the above calculation.

Calculation of the power of radiators and radiators

But in addition to the boiler, the heat supply performance is affected by the technical characteristics of other components. Therefore, you need to know how to calculate the power of the heating battery.In fact, there is a thermal transfer of energy from hot water to air in the room.

To calculate the power of heating batteries, it is necessary to actually determine their heat transfer. This is the name of the process of heat transfer from a heated body to air in a room. There are several factors that influence this indicator. The main one is the material of manufacture. The lower the heat transfer resistance of the battery, the lower the heat loss. However, along with this, the effect of energy storage must be taken into account. This is observed in cast iron structures. Since in order to calculate the power of the heating battery, it is necessary to know the level of filling it with hot water - the total area of the structure should be calculated. The total heat transfer also depends on this.

For calculations, it is necessary to determine Δt by the following formula:

Δt = ((Тпод-Тобр) / 2) -Тпом

Where Tpod, Tobr and Tpom - temperatures in the giving, return pipe and indoors.

To calculate the power of cast-iron heating radiators, you will need the coefficient of thermal conductivity of a particular material and the total area of structures. The first can be taken from standard tables. For bimetallic models, the calculation of the power of the heating radiator takes into account the steel cores of the pipelines and the aluminum heating surface.

The calculation is performed according to the following formula:

Q = Δt * k * S

Where Q - specific heat of the radiator;TO - coefficient of thermal conductivity;S - total area of the structure.

In this way, the power of the heating battery can be calculated. However, in practice this is difficult, as several factors remain unknown - the actual wall thickness, additional elements used in the manufacture. Also, in calculating the capacity of the heat supply battery, the heat losses in the room are not taken into account.

Most manufacturers indicate the rated power in the radiator passport. But this is done only for one thermal mode of heating. Therefore, taking the passport data of the product as a basis, you can accurately calculate the power of the heat supply radiator.

Actual heat transfer rates of the battery depend on the correct installation. When calculating the power of steel heating radiators, their location relative to the windowsill, floor and walls in the room is not taken into account.

Circulation pump power calculation

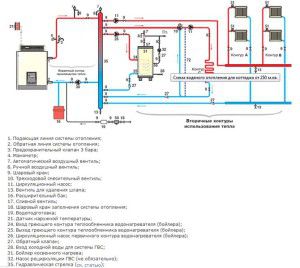

In closed heat supply systems, fluid circulation is forced. Before calculating the power of the pump for heating, it is necessary to draw up a heat supply scheme. Only after this can we begin to calculate.

There are several parameters that determine the main characteristics of this heating component. The pump is aimed at increasing the speed of the coolant in the system. In addition, it should not create excessive hydraulic loads, increase noise. That is why it is so important to correctly calculate the pump power for heating.

To perform the calculations, you need to find out the following equipment characteristics:

- Performance. It characterizes the amount of heat transferred per unit time through pipelines using a circulation pump;

- Hydraulic resistance. These are pressure losses in the pipelines due to friction of water on the inner surface of the heat supply components. When calculating the power of the pump for heating, this indicator is one of the determining ones, since the flow rate of the coolant depends on it;

- Power consumption. It is indicated by the manufacturer in the device passport. It is determined by the characteristics of the electric motor connected to the pump rotor.

At the first stage of calculating the power of the circulation pump for heating, the performance should be calculated. To do this, you need to find out the necessary heat output of the heat supply system. Performance calculations are performed according to the following formula:

Q = (0.86 * R) / (Tpod-Tob)

Where Q - device performance;R - estimated thermal power, W;Tpod and Tob - water temperature in the supply and return heating pipes.

The main factor affecting pump performance is the thermal power of the system. It’s best to calculate it as accurately as possible in order to avoid buying a device with inappropriate parameters. Also, the calculation of the power of the pump for heat supply is affected by the characteristics of the coolant. In the case of using antifreezes, the nominal indicator must be increased by 10-15%, since their density is much higher than that of distilled water.

The hydraulic resistance of the circulation pump is determined by the following formula:

H = 1.3 * (R1 * L1 + R2 * L2 + ... Z1 + Z2) / 10000

Where R1 andR2 - pressure loss on the supply and return sections of the line;L1 and L2 - the length of the pipelines;Z1 and Z2 - hydraulic resistance of system components.

The last indicator for calculating the power of the pump for heat supply can be taken from the device passport. If there is none, it is recommended to use the data from the table.

|

Heating component |

Hydraulic resistance, Pa |

| Boiler | 1000 to 2000 |

| Thermostatic valve | 5000 to 10000 |

| Mixer | 2000 to 4000 |

| temperature sensor | 1000 to 1500 |

Manufacturers indicate hydraulic resistance in the magnitude of the water column. Those. This is an indicator of power, which is able to raise water in a vertical pipe to a certain level.

When calculating the power of the circulation pump for heat supply, the presence of several speed modes is not taken into account. Although in practice, using this function of the device, you can optimize the speed of the coolant, thereby balancing the entire system.

Is it difficult to make an accurate calculation of heating a house or a greenhouse on its own? In addition to the above methods, it is recommended to use specialized programs for heat supply. This will verify the results and achieve maximum accuracy of calculations.

The video shows an example of calculating the heating power using a specialized program: