In the garage, a person has to spend a lot of time. In winter, even qualitatively performed insulation does not save, the cold makes it impossible to perform any manipulations. The way out is a stove in the garage, which you can do yourself, saving on the refusal to purchase factory-made products. In order not to make a mistake with the choice, you need to familiarize yourself with the existing types of heating appliances, their features, the principle of operation, pluses and minuses, manufacturing technology.

Features of garage heating

When choosing a stove for a garage, you need to consider that this structure is specific. The feature is as follows:

- storage of gasoline, oil, grease and other flammable materials;

- a large amount of time that the motorist spends in the garage;

- the machine requires a constant air temperature, since condensate causes corrosion and mold in the cabin;

- limited space where an increased concentration of toxic substances can lead to poisoning and even death.

Based on the foregoing, the garage oven must meet the following requirements:

- Safety. The product must not create excessive heat, emit sparks and emit toxic gases.

- Compactness. The space inside the building is extremely limited. The heater must not interfere with the arrival of the vehicle and the movement of its owner.

- The ability to quickly heat up and burn for long until the next refueling. The owner of the building is not able to often add fuel if he has a permanent job.

- Simplicity of design and the possibility of self-production. The purchase of special tools and materials can lead to additional costs and complications.

- Convenience in service and operation. The room is not intended to spend all free time on repair and cleaning of the heating device.

Familiarization with existing models of furnaces will make the right decision.

Garage Heating Methods

There are several effective and economical devices with which you can create comfortable conditions for working in the garage. All of them are easy to manufacture, differ only in the materials used and the technology of the furnace.

Potbelly stove

This is a classic, proven over centuries and millions of users. The product is simple, inexpensive and reliable. For the manufacture of used sheet metal, pipes or used gas cylinders. The heater runs on all types of solid fuel, which allows you to utilize unnecessary household goods or waste generated during the processing of the garden plot.

For burning in a potbelly stove, you can use the following materials:

- firewood;

- coal;

- peat;

- hay;

- straw;

- sawdust;

- bush;

- tops;

- old clothes;

- unnecessary furniture;

- waste paper;

- dung.

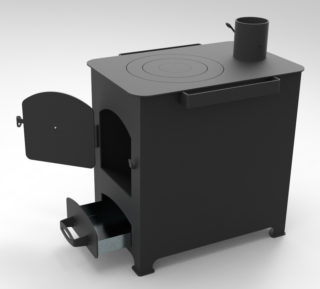

The design of the potbelly stove is so simple that even a beginner can make it. It consists of a housing in which the grates are installed, there are lockable holes for the blower, fuel and chimney. The combustion products are discharged into the street through a pipe in a natural way.

Buleryan

A boiler of this type is a structure consisting of a housing and air ducts encircling it. A feature of the boiler is the presence of two combustion chambers.The first, small in volume, is loaded with fuel. Insufficient amount of air prevents its ignition, which occurs in the second chamber, where combustible gas enters. As a result, the effect of double heating from smoldering and flame takes place.

The device has several outlet pipes to which flexible circuits can be connected and brought to adjacent rooms for heating.

The burning time of one bookmark is 6-12 hours, depending on the design of the furnace. The product is easy to operate, reliable and durable. Among the disadvantages are the high surface temperature and the need to purchase a chimney with good thermal insulation. Nevertheless, buleryan is the most optimal furnace, which can quickly heat the garage and maintain a comfortable temperature in it without frequent refueling.

Heat gun

An electric appliance is a cylindrical body, inside of which there is a fan and a heating element. Outside, control and monitoring devices are installed. The product is characterized by a high room heating rate and no less high energy consumption.

Among the advantages of the heater include compactness, reliability and performance. The device is capable of heating the garage to such a temperature in a matter of minutes that you can be in it without outerwear. There is only one drawback to the equipment. It consumes a lot of electricity, which is becoming more expensive every year. Therefore, the heat gun is used only for a one-time quick warm-up, and not for constant heating of the garage.

Oil radiator

These are affordable and safe to use devices. They are steel cases, inside of which there are heating elements immersed in synthetic oil with high thermal conductivity. Radiators of various performance classes can be equipped with temperature regulators, timers and other devices that allow you to set the necessary settings.

The advantage of oil heaters is their simplicity, reliability and durability. They can be placed on the floor and hung on the walls. Less in the limited space of heating.

Infrared heater

Infrared devices heat the objects that they are aimed at, and those, in turn, are air. Devices can be mounted on the wall and ceiling, put in any convenient place on the floor. A big plus is that the devices can work offline, without human intervention. If you set a timer, the heaters will turn on and off at the set time.

In addition, devices have such advantages:

- ecological cleanliness;

- noiselessness;

- Fire safety;

- the speed of heating the garage;

- durability.

The minus of the device is only one - high electricity bills during prolonged use.

Use of insulation

Even several high-performance heaters will not be able to save the situation in winter frosts, if you do not take measures to warm the structure. High-quality thermal insulation prevents the penetration of cold from the outside, heat leakage from the inside and the formation of condensation on the walls. It is advisable to trim the room from the outside in order to shift the dew point from the supporting structures.

The choice for external insulation of brick and iron garages is quite large:

- Styrofoam;

- mineral wool;

- polyurethane foam;

- warm plaster;

- penoizol;

When arranging the structure, the method of gluing the walls (wet facade) or the frame method is chosen, when a plate or foam insulation is applied inside the form, followed by sheathing with panels or other finishing material.

From the inside, the walls and ceiling of the garage should be treated against mold and corrosion, and then insulated with OSB or chipboard, after soaking them with an antiseptic and a flame retardant.

How to create a do-it-yourself oven

Making a homemade stove requires design skills and working with household tools. The procedure should begin by choosing the types of furnace and energy source for the furnace. After that, you need to work out a detailed drawing and purchase the necessary materials.

The manufacture of the furnace is carried out in the following sequence:

- Arrangement of the base. It must be durable and fireproof. The best option is a reinforced concrete slab. If the floor in the garage is earthen, you need to reinforce it with piles.

- Make a case. Depending on the choice of design, brick, sheet metal, gas cylinder are used. The connection of parts is carried out by welding or a binder solution.

- If diesel fuel, oil or mining will be used, connect the tank and remove the fuel line from it. Install a fuel combustion system.

- To make and fix the door, install the grate. Install a water boiler on the side or on top of the casing in order to be able to use warm water during any work.

- Make a chimney. An excellent option is a double-walled design with mineral wool located inside. Such a channel is characterized by high reliability and low thermal conductivity.

- Carry out the final adjustment and fastening of moving and stationary parts.

The final step is to check the operability of the device. A test firebox is carried out, the identified shortcomings are eliminated.

Overview of Options

To make the best decision regarding the heater manufacturing option, you should study the features of each design that you can assemble yourself.

Brick oven

Such structures are usually built in large garages, since the brick oven takes up quite a lot of space. Its walls have a large thickness, so that the hearth retains heat for a long time after burning fuel. The wood hearth is laid out of refractory bricks, which is connected by clay with fireclay powder. The optimal masonry height is 9 rows, where the 2-4 level is made of fireclay brick.

The chimney is best done from a two-layer steel pipe, around which a brick is laid. A chimney is discharged through the roof or wall if the upper tier has a complex structure.

Potbelly stove

Traditional stoves have a cylinder body. This form provides uniform combustion of fuel and heat distribution throughout the room. Since the hearth will be installed near the far wall, a decision can be made in favor of a square and rectangular section housing. It is advisable to use a steel pipe or a cubic expansion tank as a preform. The wall thickness of the metal must be at least 5 mm. Welding points must be reinforced with steel corners and rivets. To increase the productivity of the stove, thick steel sheets that perform the function of a radiator are welded to its sides.

The first 150 cm from the boiler, the pipe wall thickness should be 3 mm, and the diameter should be at least 120 mm. If the chimney is led outside through the wall, the links are connected by adapters with an angle of no more than 30 degrees.

Development furnace

This type of construction allows for free and useful use of used oil, which is abundant in any garage cooperative or holiday village. Oil is a good fuel that releases a large amount of energy during combustion. A byproduct is strong soot. To collect it, a filter is installed on the pipe head. Exhaust air filters can be used for the engine.

A furnace from two chambers is going to. The first is a tube with a nozzle at the end. The liquid is preliminarily burned in it, and the hydrocarbons released through the hole enter the second chamber. Afterburning of fuel occurs, accompanied by the release of high temperature. Adjustment of the combustion rate is carried out by a crane and air dampers.

Long burning furnace

The product is made from a 200 liter barrel or sheet steel with a thickness of 5 mm or more. In the chamber where the firewood is loaded, there is no burning. Fuel smolders from top to bottom, completely fading for 10-20 hours, depending on the size of the outbreak and the amount of loaded energy.

On the upper part of the furnace body, a chimney and air duct are fixed for air supply. Thanks to this solution, traction is practically absent.

The intensity of combustion of firewood is regulated by side flaps. The rest of the design of such a heater repeats the device of a classic stove.