The use of insulation can reduce the cost of building materials and maintain a comfortable temperature in the house. There are many requirements for modern thermal insulation in terms of strength, environmental friendliness and level of thermal conductivity. Among the materials on the market, basalt wool meets most of the criteria. Baswool insulation is available in a wide range. Among the products there are options for external and internal insulation, sound insulation and fire protection.

Popular varieties of insulation Baswool

Minvata Basvul is a heat-insulating material based on basalt rocks. Brand products are produced at the factory with modern automated lines. The fibers are high-quality, their chaotic weave provides numerous air cavities. Baswool brand offers materials for all types of insulation:

Light

Heaters of the Light series have the lowest density and price. This is a budget option for thermal insulation of non-loaded sections of the building. The manufacturer produces 3 types of plates, their labeling indicates the density. Insulators Baswool Light 45 are recommended for thermal insulation of the floor and roof, Light 35 is better to lay in the attic or attic. Basalt cotton wool with a density of 30 kg / cu. m used for interior partitions.

Ruf

Roof basalt slabs are high density roofing insulation. They are stacked with a single-layer roof insulation. The density of the material is 140-160 kg / m3. Modifications with the designation "H" and "B" are intended for installation on a flat roof as the lower and upper layer. Products have compressive strength in the range of 35-80 kPa. Long-term operation of the roofing cake provides a record density of up to 190 kg / cu. m. Another positive feature of roofing insulation is low water absorption - 1.5%.

Facade

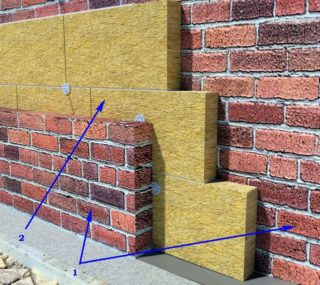

The use of basalt plates to warm the facade of the building allows you to maintain a favorable microclimate without additional heating costs. The range of insulation for exterior walls includes:

- Facade - hard basalt litas with a density of 110-160 kg / cu. m designed for plaster.

- Vent Facade - insulation with increased hydrophobization, used in the installation of ventilated facades. Mineral wool does not experience increased loads, so its density does not exceed 90 kg / cu. m

A significant area of the walls leads to heat loss with insufficient insulation of walling. Basvul - a heater that quickly and reliably cuts off the cold from the interior.

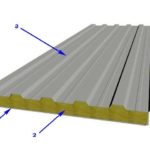

Sandwich

The multilayer insulation design is in demand in the production of sandwich panels for frame houses. Two types of products are produced:

- Sandwich C - the outer layer of wall panels is a metal sheet, plates with a density of 100-110 kg / cu are used as insulation. m

- Sandwich K - roofing panels require the use of material with a high density - 120-140 kg / cu. m. External coating of painted metal construction.

Plates are protected from moisture by hydrophobic impregnation. The material is used in the construction of administrative and commercial buildings, kiosks, garages. Sandwich panels with basalt wool have a fire safety certificate.

Flor

High-quality floor insulation will provide thermal insulation Baswool series Flor.Strong plates are used under the screed, as part of the "floating" floor, to isolate the floors. Basalt wool can reduce the level of noise penetrating between floors. The material is not afraid of moisture, it is used for flooring on the ground. The mechanical strength of the insulation is due to its high density. The modification Flor has 100-120 kg / cu. m, Flor P - 160-180 kg / cubic m. The use of mineral wool significantly reduces heat loss. It is recommended when installing the underfloor heating system.

Standard

Universal insulation for insulation of wall structures. It is widely used as a middle layer for well masonry. Standard slabs are characterized by an average density of 50-7 kg / cubic meter. m. Many air spaces provide a minimum indicator of thermal conductivity. Material significantly reduces noise penetration. Basalt wool is not deformed during operation. It can be laid under the exterior siding.

Ecoroc

The Baswool Ecorock series is lightweight mineral wool slabs designed to insulate pitched roofs, attic ceilings and floors along logs. The material has the lowest density among the manufactured products. Safe use inside residential buildings ensures a minimum amount of binder.

- Standard

- Sandwich

- Ecoroc

Technical characteristics of insulation Basvul

Basalt slabs are characterized by high strength and fire resistance. They withstand temperatures up to 1000 ° C. The material has a chemical inertness. In contact with metal, it does not cause corrosion. Mineral wool is neutral to biological effects. With increasing humidity, mold and fungus spread on it. Rodents and insects avoid basalt slabs due to the stickiness of the fibers.

The main parameters of the insulation:

- Thermal conductivity - 0.035-0.042 W / m * K.

- Compressibility - 10%.

- Vapor permeability - 0.3 mg / m * h * Pa.

- Water absorption - not more than 2% of the volume.

- Density - from 30 to 200 kg / cubic m

- Combustibility class - NG.

In the production of insulation Basvul is treated with a hydrophobic compound. Basalt slabs hardly absorb moisture. At the same time, they easily pass water vapor, regulating the microclimate in the room.

The standard dimensions of the plates are:

- length - 1200 mm;

- width - 600 mm;

- thickness - 30-200 mm.

The composition of basalt wool contains organic binders. Their share in the total volume does not exceed 2.5-4%. All types of plates are packed in shrink film, which protects the material from external influences.

Features and differences from competitors

Basalt basalt slabs are a non-combustible insulation with a long service life. The material has many advantages:

- resistance to fire;

- low thermal conductivity;

- excellent sound insulation;

- vapor permeability;

- hydrophobicity;

- resistance to deformation;

- light weight.

According to thermal and noise insulation characteristics, the insulation is similar to other popular brands - Rockwool, Knauf, Park. The advantage of Basvul slabs is noticeable in costing. The cost of the material is lower than that of competitors, so warming the house will cost less.

Scope of application

Basvul heaters are used in private construction, in the construction of multi-storey residential buildings and industrial facilities. Basalt slabs are used for wall insulation according to frame technology, when installing ventilated facades and insulating structures in a wet way.

The scope depends on the density of mineral wool. Rigid slabs are recommended for areas with a high load - a flat roof, facade, floor. Lightweight insulation is suitable for heat and sound insulation of frame partitions of attic floors, pitched roof.

Features of material laying

The technology of laying basalt plates depends on the location of the insulated area:

- Roof thermal insulation - when using basalt wool for pitched roofs, installation of the battens on the rafters is necessary. The best option is to choose slabs of equal thickness to the rafter. The heat insulation pie includes a vapor barrier and a windproof membrane. After gluing the roll materials, a counter-lattice is stuffed for laying the roofing.

- Floor insulation - when choosing plates, an indicator of compressive strength is taken into account. Recommended rate of 10%. When laying on logs, the insulation is not loaded, you can choose the option of lower strength. To protect the basalt cotton wool from moisture, a waterproofing sheet with an overlap of 10-15 cm is laid on top of it. Rigid slabs are taken under the screed. Waterproofing is laid under them, and a reinforcing mesh is placed on top.

- Wall insulation - protection against the cold is located inside or outside the building. Before installation, the surface of the walls is cleaned of dirt and primed. The frame is mounted with a step of guides of 60 cm. Basalt cotton wool fits tightly between the bars. From the inside of the room, the insulation is covered with a vapor-permeable membrane and sheathed with drywall.

- Thermal insulation of the facade - when installing a ventilated facade, installation of the frame will also be required. Basalt slabs are laid in grooves and secured with plate-shaped dowels. A windproof film is laid on top of the insulation and a crate is placed under the facade coating. When using the wet method, mineral plates are attached to the walls using special glue. Rigid products designed for increased load are used. A reinforcing mesh is attached to the cotton, which is the basis of decorative plaster.

The general requirement for installing Baswool mineral wool is to work in dry weather. If the humidity exceeds 45-50%, the material may get wet. Moisture degrades the performance of stone wool.

Basalt basalt insulation is a modern safe production technology, fire protection and low thermal conductivity. The material is affordable and easy to use. Insulation of the house with basalt plates is easy to do with your own hands.