If it is necessary to replace radiators in a private house or apartment, two options are possible, each of which is selected at the discretion of the homeowners. Most of them are inclined in favor of inviting specialists to the house who will install the heating radiators very quickly and guarantee high quality work. But if there is some experience and after studying the proposed material, the user will be able to replace the batteries with their own hands, saving on the salary of the invited plumber.

Tools and materials for installation

Before you install a heating battery in your home, you need to prepare the necessary tools and related supplies. Of the kit for mounting a radiator in an apartment, you will definitely need:

- electric drill with a set of drills;

- level type "level";

- Adjustable wrench and pliers.

The range of accessories and consumables needed to replace the heating system is more diverse. In addition to special plugs and steel brackets, it includes a number of plumbing products and materials:

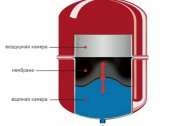

- Mayevsky crane (or air bleed device);

- two ball shut-off valves;

- fittings providing a tight connection of pipes and radiator pipes;

- FUM tape (or linen winding).

In addition, you will need to prepare a set of dowels of a suitable size and other fastening elements.

Choosing a place to install

The place for mounting radiators is usually chosen directly below the window. This is done not at all by chance and not simply out of a desire to abide by traditions.

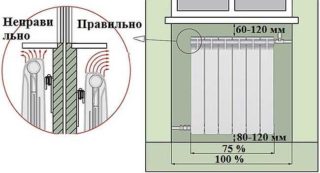

Installing heating batteries just below the window sill allows upward flows of well-heated air to cut off cold masses. In addition, its warm layers heat the glass, eliminating the effect of condensation and fogging of the windows. This will require that the radiator in width occupy most of the opening (up to 70%).

It is equally important to determine in advance at what height the radiator is installed, and whether there is sufficient clearance remaining between its lower part and the floor (at least 8-12 cm). With this arrangement, the heating system will heat the legs and accumulate heat well in the middle zone. In accordance with current standards (SNiP), an acceptable distance to the window sill is also specified, which is selected on the order of 10-12 cm. This will allow warm air to easily go around the barrier and rise to the window panes. The last requirement for the location of the battery is the remoteness of its internal plane from the wall, it is regulated by the current standards within 3-5 cm. If this condition is met, there will be no difficulties with free space during the installation of radiators.

Connection Methods

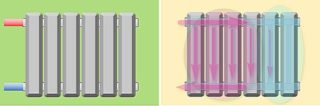

Among the most commonly used methods for connecting radiators, the following three options are distinguished:

Among the most commonly used methods for connecting radiators, the following three options are distinguished:

- diagonal connection - with upper input and lower output on the other hand;

- seat scheme;

- one-way connection - with lower and upper eyeliner.

The diagonal scheme is considered the most effective, since it takes into account all the possible factors leading to heat loss. With its help, it is possible to realize the capabilities of radiators of any type with maximum return.

In the calculations of most heating systems, it is this method of connection that is taken as the sample, taking into account the correction factor for possible deviations.In this case, when the energy carrier moves, no obstacles are encountered in its path. It completely fills the entire volume of the upper collector, and then gradually flows through the vertical channels into the lower sections. As a result, the entire working area of the battery warms up evenly, ensuring maximum heat transfer.

Lower through (saddle) connection

The lower way to connect heating radiators is the most inefficient in terms of losses, which with a two-pipe system reach 12-15% or more. When moving, the coolant chooses the shortest path and is not able to transfer heat to the upper collector. The result is uneven heating of the battery area and an increase in fluid flow.

The situation is even worse when lateral eyeliner is used with a single-tube version, in this case the losses increase to 20-22%. For obvious reasons, the conditions for uniform distribution of the coolant over the area of aluminum or cast-iron batteries in this case are even less than with a 2-pipe inlet. Despite the significant amount of losses, this method of connecting pipes is in demand in situations where a hidden installation of inlet and outlet pipe communications is needed.

One way connection with bottom (top) feed

In terms of efficiency and efficiency, this circuit for connecting to heating is even worse than the previous case, since the coolant is removed from the same side as it is introduced. The likelihood of stagnation in areas remote from the inlet fitting further increases. Due to the fact that the carrier strives to find the shortest and easiest path between the two nozzles (inlet and outlet), it does not affect the upper layers, and it also does not have access to all other spaces that are far from the working supply of the device.

One-way connection with lower feed is used in exceptional situations when the pipes to the battery cannot be connected in any other way. Its use is a necessary measure, forcing the owners to put up with low heating efficiency.

A slightly better option is the upper one-sided lateral eyeliner, in which the space volumes remote from the input do not warm up well. But in this case, the carrier has the opportunity to descend to the lower "floor" of the collector and heat the zone closest to the fitting.

Types of heating systems

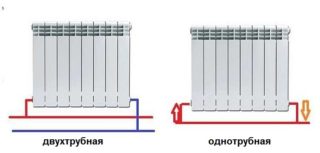

The amount of heat received from the radiators depends on the type of connection and the type of heating system regarding the number of pipes used. To determine this indicator, it is advisable to understand how single-tube systems differ from double-pipe circuits.

Single pipe heating

This type of heating organization is the most economical when viewed from the point of view of installation costs. The estimate of the work in this case is approximately two times less than the cost of arranging a 2-pipe circuit. For this reason, it is most often found in multi-unit and multi-storey buildings, although it is not considered a rarity in the private sector. With this scheme, radiators are connected to the mains in a sequential chain: the coolant, passing through the next heating unit, enters the input of the next, etc.

The outlet fitting of the last radiator is connected to the riser of a multi-story building or to the entrance of a heating boiler.

The disadvantage of a single-tube wiring option is the inability to separately adjust the heat transfer level of the batteries. After installing a thermal head on any of the series-connected radiators, it extends its effect to the entire system. Another significant disadvantage of this method is the uneven distribution of the temperature of the coolant in different parts of the heating chain.Elements closer to the riser or boiler will heat up well, and the sections removed from them will receive very little heat. The disadvantages include the inconvenience of repairing such systems, when in case of failure of one element it is necessary to disconnect all sections and drain the carrier. To avoid this, experts advise installing jumpers between the supply pipes - “bypasses”.

Double pipe wiring

The two-pipe heating system has two piping threads in its piping, which are commonly referred to as “supply” and “return”. In this case, each radiator is connected to both lines at once, which means parallel connection to the system. As a result, a coolant with the same temperature enters their inlet fittings. Another advantage of this method is that it is allowed to install “your own” temperature regulator on each assembly section.

The disadvantages of this type of heating include an increased number of pipe elements. During installation and wiring of the system, their number is almost doubled in comparison with the single-tube version. On the other hand, this connection ensures high heat dissipation when working with any heating equipment, including gas boilers.

General installation procedure

Before you connect the heating battery correctly, you will need to familiarize yourself with the general provisions regarding the installation of systems with piping from polypropylene pipes:

- Before installing the heating batteries, a plumber is required to disconnect the current system from the load; in a private house his help is not required;

- radiators are installed in accordance with the instructions attached to most products;

- upon completion of all work, a control test of the system is carried out for leaks in the interfaces.

When choosing radiators for their home, experts advise to pay attention to the famous German company "Rechau", whose products are of high quality and good heat dissipation.