A heat exchanger for heating is a technical device that transfers heat between hot and cold environments. Devices of this type used for heating systems are divided into several categories depending on the principle of operation, the interaction of the media, the method of heat transfer, as well as the direction of movement of the carrier and the heat consumer. When choosing a heat exchanger for a house or a bath, the features of a particular heating system, the pros and cons of the device, its design and additional functionality are taken into account.

The device and principle of operation of the heat exchanger

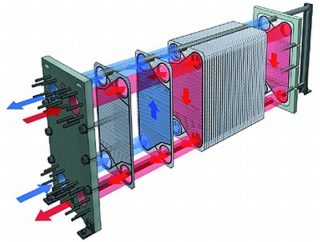

The design of the heat exchanger directly depends on its type. Modern appliances for heating consist of two pressure plates with holes to which additional elements of the pipeline are connected. The carrier and heat consumer also enter the device due to the presence of openings. The principle of operation of the heat exchanger is quite simple, it can be considered on the example of a plate unit. The heat flow in such a device affects the corrugated layer in it, gradually gaining speed during operation.

After the start of the first stage of the medium, they begin to move towards each other on both sides in order to avoid mixing. On the plates located in parallel, working channels are formed, while moving through them in each medium, heat exchange occurs, as a result of which the heat goes beyond the unit. In home or bath plate units, internal flows can go according to a one-way or multi-way type scheme, taking into account technical characteristics and specific conditions.

Before choosing a device, it is useful to read information about why a heat exchanger is needed, find out about the types of the unit, the rules for its installation and operation.

Types of operation

By the method of medium interaction, heat exchangers can be surface and mixing. The connection diagram of the mixing heat exchanger is considered more complex.

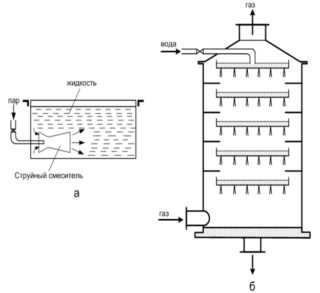

Mixing

The work of mixing units is based on the contact of two substances and the mixing of the consumer and the heat carrier. The mixing heat exchanger for heating is divided into several categories, this includes cooling towers with a chimney, steam bubblers, as well as barometric condensers and nozzle heaters.

Surface

The surface heat exchanger operates in the boiler room by transferring heat through the contact surface. It can be plates or pipes depending on the type of device. The media inside such units do not mix with each other, what is their main difference from mixing analogues.

According to the principle of heat transfer, surface heat exchangers are divided into two types: regenerative and regenerative.

- The principle of operation of the recuperative heat exchanger is based on the continuous transfer of heat through the contact surface. Thus, many plate-type devices work.

- A standard or secondary regenerative unit is designed to cool and heat the air. In these devices, the movement of the carrier and the heat consumer occurs in a batch mode. Such installations are often used in office high-rise buildings.

Recuperative devices are divided into two categories depending on the surface. It can be made of pipes, this option is designed to work in conditions of high pressure drops.Devices with a sheet surface are more compact and lightweight, so the installation of a heat exchanger of this type is almost no problem.

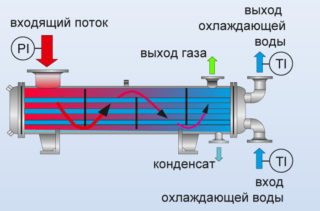

Shell and tube

The shell and tube device is made of ribbed tubes that increase the surface area that transfers heat. It can have a design including tube sheets, with a rigid coupling of all parts and elements. Lattices in such a device are welded to the walls of the body, pipes are attached to the hitch to it. The design with a floating head is considered more perfect, devices of this type are more expensive, but are considered more practical.

Submersible

Devices of this type are often installed in high-rise buildings. They installed a coil in the form of a cylinder, placed in a vessel with liquid. Due to the simple design, the time for heat transfer is noticeably reduced.

Spiral

The strapping of such a heat exchanger consists of metal sheets twisted into a spiral and fixed to a roll. Units of this type need good sealing. You also need to consider that installing a spiral heat exchanger requires special skills. Spiral devices are not used in systems with a pressure of more than 10 kgf / cm2.

Lamellar

Lamellar appliances are deservedly considered the most advanced and ideal for both private homes and industrial premises. They do not cause problems during assembly and cleaning, have a minimum degree of resistance to hydraulics. The scheme for supplying the working medium to them can be carried out in three ways: straight-through, mixed, and countercurrent.

- Submersible

- Spiral

- Lamellar

- Shell and tube

Advantages and disadvantages

Modern units are easy to maintain and do not cause problems during disassembly and flushing of the device. The plate heat exchangers, which are installed most often, are polluted more slowly due to increased turbulence and high-quality polishing.

Thermal units from leading manufacturers last longer than water boilers, domestic hot water boilers and stoves for homes and garages. The average life of the unit is about 10-20 years. Most devices have virtually no flaws, except for the need to clean the device as it becomes dirty. To reduce the accumulation of dirt inside the device, you must always use a quality coolant.

Selection rules

The list of basic criteria that you need to pay attention to when choosing includes:

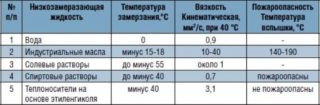

- type and quality of thermal carrier used;

- simplicity of disassembly and assembly;

- type of heat transfer;

- the ability to increase capacity during operation.

Lamellar exchangers are more often used for cooling and heating systems for refrigerators and pools, spiral exchangers are used in various industries, horizontal ones are better suited as heating devices.

Operation and maintenance

Timely inspection, prevention and replacement of parts will help to save on the repair and purchase of a new device. The operation of the unit is negatively affected by the processes of corrosion and erosion of parts, frictional wear during increased vibration, as well as exposure to high temperatures.

If you do not fix the problems on time, the design may fail. You can clean the device yourself or entrust it to a specialist.

Popular manufacturers

Collapsible and soldered heat exchangers from the RIDAN and ASTERA brands, which are distinguished by a high level of quality and the availability of the necessary spare elements, have proven themselves in the Russian market.

Of foreign brands, customers are more likely to choose diesel and standard devices from ALFA LAVAL, DANFOSS and SONDEX.

When choosing a unit, it is necessary to take into account the features of the system as a whole, the estimate, if it is a project, requirements for the number of kW, as well as other necessary parameters.