The brand of the German company for the production of insulation materials for the construction industry of the Knauf Insulation brand includes Ecoroll insulation. This is a type of thermal insulation for building structures, an inexpensive budget option. It is based on fiberglass, among the components there are no formaldehyde and acrylic binders, which makes the product environmentally friendly.

Specifications

The heat-insulating material has a porous structure, numerous voids are filled with air, which reduces its thermal conductivity. A layer of 50 mm is enough to provide a brickwork effect, a thickness of a brick.

Characteristics of the insulation Ecoll:

- density - 10-13 kg / m3;

- thermal conductivity in the initial state - 0.038 W / (m * K);

- thermal conductivity during operation - 0.044 W / (m * K);

- combustibility - NG;

- sound absorption - 45 dB;

- tensile strength - 0.005 MPa;

- water absorption - 1.5%;

- humidity not more than 0.5%.

The given data testify to high consumer qualities of Ecoroll thermal insulation.

Varieties of thermal insulation Ecoroll

Insulation Knauf Ecoroll - mineral wool, the filler of which is basalt chips or other natural minerals. Available in rolls, in plates or in the form of cylinders. Roll insulation has a width of 1220 mm, a thickness of 50 mm, a roll length of 6800 or 8200 mm.

Plates of Ecolloll mineral wool are used for thermal insulation of ceilings and walls. The most commonly used thermoplates brand TR 040 or TR 044, thickness 50 and 100 mm. Shrink wrapped packaging contains 8 or 16 units, depending on the thickness. Being in a compressed state, they occupy a small volume and are convenient for transportation.

Insulation Ecoroll Extra is available in the form of mats measuring 1230x610 and a thickness of 50 or 100 mm. It has a water-repellent impregnation, which greatly expands the scope.

Cylinders are used to isolate pipelines. They have four varieties:

- outer coating of metal foil, which increases resistance to mechanical stress;

- unfolded coating, can break down under high physical exertion;

- by density - from 65 to 145 kg / m3;

- by wall thickness - 1-20 mm;

- according to the inner diameter - 1-140 cm.

Cylindrical heat insulators are used when installing chimneys in residential buildings, bathhouses or boiler rooms.

Advantages and disadvantages

Among the characteristics of the insulation Ecoroll note a number of advantages of the material.

- Natural, environmentally friendly. It does not cause allergies.

- Not toxic, not dangerous to humans and living things.

- Provides a high level of thermal insulation, due to its low thermal conductivity.

- Isolates the room from noise.

- Not combustible. It creates a barrier to the spread of flame, can melt at high temperature, while not emitting harmful substances, does not cause smoke. This allows its use in residential and public buildings.

- The high density of thermal insulation of Ecoroll makes it resistant to moisture.

- Vapor permeability prevents the formation of moisture and mold on insulated surfaces.

- Light weight eliminates the increase in load on building structures, facilitates transportation and loading.

- There is no unpleasant odor.

- It is not damaged by rodents and insects.

- Easy to cut and stack thanks to its soft texture.

- Universality of use.

- Long term of operation - 50 years.

Among the shortcomings, a high price is noted, although the price / quality ratio eliminates this disadvantage.

Material scope

As a heater, Ecoroll is widely used. This is facilitated by its positive characteristics. A high degree of vapor permeability allows it to be used in combination with breathable materials - wood, foam concrete, aerated concrete.

Knauf thermal insulation industry:

- attic, interfloor, attic floors;

- walls of buildings made of various materials;

- floors, internal walls and partitions;

- trunk and local pipelines;

- steam lines, ventilation and air conditioning systems;

- chimneys.

Ecroll roll materials are used to isolate horizontal structures - floors along the logs above basements and soil or in attics, attics and floors. It can be used for thermal insulation of pitched roofs, external walls, internal partitions between rooms with a temperature difference. Roll insulation should not bear additional load on the material.

Thermal plates Ecoroll is a plate insulation for roofs, walls, ceilings. Created using 3D-elasticity technology, it fits tightly to building structures. Using it you can forget about the cold bridges.

Plates are produced with a thickness of 50 or 100 mm. Thermal insulation with a thickness of 100 mm is more convenient to use. Faster and easier installation, no need to lay two layers, fewer operations and waste. Plates are laid by surprise between the roof rafters or floor logs.

Installation of mineral wool Knauf Ecoroll

Warming of a wooden floor

Work order:

- The rough floor is cleaned of debris and dust, primed, covered with sheets of roofing material.

- Lay out pre-prepared logs.

- Cover the floor and logs with waterproofing material.

- The waterproofing strips are overlapped, glued together with mastic or construction tape, the material is fixed to the lags with a stapler. The waterproofing layer should go on the walls to a height of 15 cm.

- The insulation is laid out between the lags. Plates are pre-cut, their width makes 3 cm more than the distance between the lags. The rolled web is cut in place. It is important that there is no uncovered space. If several layers of insulation are laid, the connecting seams are placed with a shift of 15-20 cm.

- Next, lay a vapor barrier. To avoid film shear, it is attached with a stapler to the insulating layer, the joints are glued with mastic.

After laying the insulation between it and the floor covering there should be a gap of 2-3 cm for air circulation.

Roof insulation

When installing an attic or a living room in the attic, it is necessary to carry out roof insulation. For this, stove insulation is used. It is important to prepare the room before work. Rafters should be dry, without damage from moisture and fungus, in the attic should be a positive temperature.

From the roofing insulation must separate the waterproofing layer. Plates are placed in the space between the rafters, fastened with metal brackets. Joints of adjacent elements are coated with mastic or joined with construction tape. A special fiber or film is laid on top, which provides vapor barrier. An air gap must be left between the thermal insulation layer and the inner lining of the ceiling.

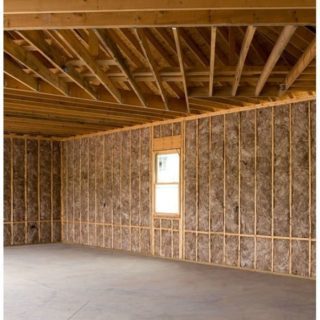

Wall insulation

Mineral wool mats 50 and 100 mm thick are used for wall insulation. The insulation is glued to the leveled base with building glue. This ensures a tight adherence of the material to the base, which is important for thermal insulation. The basis for Ecoroll can be structures made of wood, concrete, brick, silicate blocks.

Methods for bonding insulation

The glue is applied to the slabs in a continuous layer or around the perimeter of the slabs. The continuous layer is leveled with a notched trowel over the entire surface. This method is suitable for gluing onto perfectly even surfaces. If there are irregularities on the walls, the edges of the plates along the perimeter are smeared with adhesive, the width of the strip is 100 mm. In the center, 8-10 strokes are made with a diameter of 100 mm. The thickness of the adhesive layer is 3 mm.

The glued plate is pressed to the base with your hands, then straightened to the edge using the rule. Glue should not get into the seams between the plates. Joints are glued with tape. A reinforcing fiberglass mesh is applied to the insulation, which is glued to the base. Then perform a leveling layer and a primer surface. After 2 days, apply decorative plaster, paint the walls.