Rockwool insulation is one of the high-tech and environmentally friendly materials. It is widely distributed in various fields. Due to the quality of the material, it is safe to use even at home. Raw materials have a state certificate of conformity.

What is Rockwool

Rockwool is a company that specializes in the production of insulation and soundproofing materials. The brand began to exist in 1936. It was previously registered in Denmark and at first carried out the sale of certain minerals: coal and rocks.

Thermal insulators are made on the basis of stone wool with the addition of wool. Ready-made raw materials are high-quality and durable. The company has its own research center, which develops unique technologies for the production of insulation. This material deserves the trust of consumers in more than 18 countries around the world. In the early 70s, the Rockwool brand gained distribution in the regions of the Russian Federation.

Scope of application

Due to its characteristics, the insulation has a wide scope.

- In construction. To use the material in this direction of steel primarily due to the positive properties and effectiveness of thermal insulation. Raw materials are used in the design of partitions and ceilings in multi-storey buildings. Also used during the construction of cottages and private houses for concrete screed.

- In ventilated and non-ventilated facade systems. For the construction of partitions, which will later be designed as a facade, they try to use ROCKWOOL of sufficient elasticity. They carry out not only heat-insulating, but also bearing function.

- When insulated from the inside. Rockwool basalt insulation is used for this purpose. It is mounted indoors on walls facing the street. Also suitable for insulation of other types of partitions, ceilings, floors of any design.

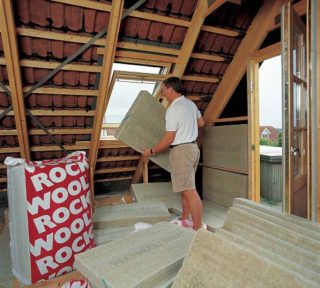

- For the roof. Most often used for insulation during the organization of the roof. Shows excellent operational properties for thermal insulation of attic rooms and attics.

- ROCWOOL in the form of cylinders has special properties for thermal insulation of pipelines of any size. Such material is securely attached to the surface of the highway, does not require preliminary preparation.

The assortment includes Rockwool plates of increased rigidity. They are suitable for the insulation of wall wells, as well as for the insulation of street walls or the interfloor.

When calculating the amount of material for thermal insulation, it is necessary to be guided by the norms of SNiP and the formula R = R1 + R2 + R3.

Material Specifications

Thermal insulation material is famous for its good performance characteristics, due to which it deserves its attention.

- Reduced heat transfer, due to which up to 70% of the generated heat is stored in the insulated room.

- Fire resistance. Minvata Rockwool is characterized by high fire safety, as it belongs to the class of non-combustible materials. Withstands temperatures up to 1000 degrees.

- Resistance to deformation. During installation, the material may slightly change in structure, but it quickly recovers in shape.It is not subject to mechanical stress, so it can be safely used for insulation of facades.

- Good vapor permeability. The material slightly absorbs moisture, however, has the ability to accumulate it. Therefore, together with the insulation, it is also necessary to install waterproofing.

- Soundproofing. One of the important properties possessed by Rockwool stone wool. This quality is achieved due to the presence of an air layer - in the middle of the composition all sounds are held.

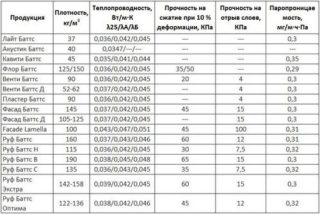

Rockwool thermal insulation specifications may vary depending on the model and its intended use.

Benefits of Rockwool Minerals

Thermal insulation from the ROCKWOOL brand is able to compete with various materials of a similar purpose due to the following qualities:

- The material is environmentally friendly despite the presence of formaldehyde salts in it. All of them pass through the polymerization process, therefore, toxic gases do not evaporate during operation.

- It is a barrier against shock noise and vibration. Almost all street work (in particular, construction) is not audible in the room due to the unique structure of the insulating layer.

- Basalt slabs practically do not get wet if properly mounted. Even the smallest violation of the integrity can cause regular accumulation of moisture, which will result in the appearance of dampness and fungus on the walls. Therefore, it is important to properly fix the material to the surface.

- Durability of a heater. Achieved thanks to the random placement of mineral wool fibers.

Also, users note the quick and convenient installation of the heat insulator due to its unique structure.

ROCKWOOL boards are perfectly cut without losing their factory geometric shape.

Insulation safety

Stone-based cotton wool is considered one of the safest. The manufacturer was the first to receive the well-deserved EcoMaterial Green certificate of conformity. Therefore, the insulation is available for use in any children's, medical and public institutions. Such material is exclusively of natural origin, safe resins are used for the binder.

Due to the presence of a European certificate, it is acceptable to use Rockwool insulation in residential conditions. Phenol is absent in the structure. For this, the manufacturer used high-tech binder resins in the solid state.

Mounting Methods

In order to properly install thermal insulation on the exterior wall of the house, you can use special fixing dowels or an appropriate adhesive base.

The use of special glue

If high-quality and expensive cotton wool is used to warm the facade, it is necessary to use glue of the appropriate quality. There must be a sufficient amount of binder in this material. Depending on the mass of insulation mats, it is necessary to select a fixing base. To fix a heat-insulating cloth to a surface, it is necessary:

- pre-print the material and leave for a day;

- find the wrong side and mark the location for the glue;

- stir glue according to the recipe indicated on the package;

- along the perimeter make strokes with a spatula;

- gently lift the material and fix it in the right place on the wall.

It is better not to combine different adhesives with each other in order to save. This will negatively affect the tightness of the heat insulator.

Mounting on building dowels

First you need to determine what structure the basalt wool has, since there are different types of dowels for solid and porous insulation. To calculate the number of fixing tools, you need to know the height of the building and the wind zone. Approximately 6 dowels will be needed to install one square meter of insulation.

At the corners of buildings there is always more wind power.Here you need to more reliably fix the insulation layer. Therefore, the number of fasteners needs to be increased.

Often practicing the combination of glue and dowels when installing insulation for Rockwool walls.

Rockwall Scandic and Standard

Both materials of the same company are well distributed and have a sufficient number of advantages. However, they differ in several properties.

| Characteristic | Rockwalk Scandic | Rockwool Standard |

| Compressibility | 30 % | 60 % |

| Packaging | Compactly sealed blocks | Plastic wrap |

| Dimensions | 800-1200 mm | 1000 mm |

| Thickness | 50-200 mm | 50-100 mm |

| Application | Does not endure a heavy load | For non-loaded structures |

| Availability of XL Modifications | there is | no |

Both heaters do their job well, so the demand for material is increasing every year.

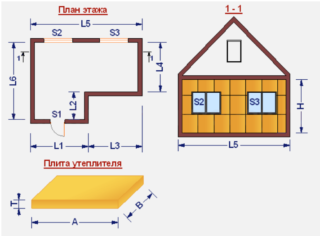

Calculation of the required quantity and thickness

When organizing the insulation of buildings, they must first pre-calculate the number of mats that will be required for a tight cladding. Not the last value is the insulation thickness of Rockwool. In the calculation, they are guided by the following components:

- climatic conditions;

- required indoor temperature;

- type of room: house, apartment, room, basement;

- height and length of the walls.

It is mandatory to indicate whether the structure has additional layers: concrete floors, beams or blocks.

If it is necessary to insulate an area of 90 square meters. m in the Crimea, where the climate is fairly moderate and warm, the volume of material should be 13.5 cubic meters. Be sure to use a stock of 1-1.5 cubic meters.