Boilers provide independence from utilities, supplying people with water around the clock and at any time of the year. If a safety valve is dripping in a water heater, this circumstance should be considered objectively, without nerves and manifestations of emotions. First of all, you need to understand that the tap is designed for water to drip from it. The only question is how often this happens and what volumes of fluid leave the tank per unit of time. A calm analysis of this phenomenon will help to understand the nature of its origin, to take effective measures to eliminate the malfunction.

The main functions of the safety valve

The first water heaters went on sale without components; in the packaging of modern products there is always a safety valve. The installation and operation instructions for the tank state that the operation of the boiler without this part is strictly prohibited. The manufacturer indicates the location and method of mounting the valve. This recommendation is justified by the fact that the tanks have a limited margin of safety, and the excess internal pressure can simply break them. Such a situation is extremely dangerous for the life and health of people, can cause large-scale flooding of several apartments in a multi-storey building.

The main functions of the check valve:

- The discharge of water from the tank when it expands when heated and begins to put pressure on its walls with a force greater than that provided by the calculated data. Depending on the pressure level, water may run or drip at different intensities.

- Water shock compensation. During such phenomena, the water pressure rises to values that are critical for domestic boilers. Thanks to a well-thought-out emergency mechanism, the faucet reduces the pressure by ejecting liquid through a special pipe.

Most often, water is dripping from the boiler through the valve at night, when the volume of its consumption decreases several times, and the pressure remains the same. The sound of falling drops can annoy the household, but this is not the worst. The main thing is that emergency valves work properly, nothing threatens people. You can easily get rid of noise - just attach a bandage, a rope or a long piece of cloth to the nozzle and bring it into the bathtub, sink or toilet bowl. Subsequently, the material should be exchanged for an elastic drainage tube.

Principle of operation

The non-return valve is a direct-acting pipeline safety valve designed to protect water-heating equipment from mechanical damage under the influence of critical pressure. The principle of operation is to automatically adjust the water pressure inside the boiler. When it reaches its limit value, water is released. Release is carried out until pressure reaches operational indicators.

The accuracy and functionality of the safety valve is determined by the parameters and settings of the internal parts.

Types and arrangement of valves

By their design, products are divided into monolithic and collapsible. The first are a monoblock, inside of which parts are pressed in. The second option is equipped with a hole through which, after unscrewing the cover, access to the inside of the product is possible. Valves also differ in the way they drain.At some drops fall from the protruding branch pipe, others are equipped with a closed pipeline system with a drain into the sewer.

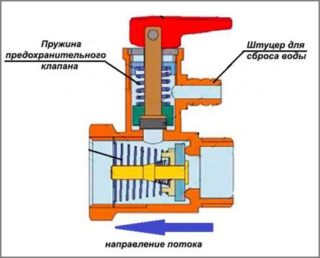

General arrangement of safety valves:

- Body. It has an internal, external mounting thread and a side pipe. Made of steel or brass. It can be coated with nickel, chrome or zinc.

- The big cylinder. Located at the bottom of the chassis. It opens when the mixer is opened and to fill the tank. It closes after the pressure inside the tank and in the water supply system equalizes. Prevents water from flowing back into the feed pipe.

- Small cylinder. Located in the middle of the product, equipped with a more powerful spring. It is compressed when the water pressure in the boiler or water supply exceeds the set rate. A drainage hole is released through which fluid flows.

Quality products from leading manufacturers are clearly marked by molding during molding. There are no visible seams or other defects. The branded parts are accompanied by a certificate of compliance. The price of such a product can reach up to 1000 rubles, but the security is worth it.

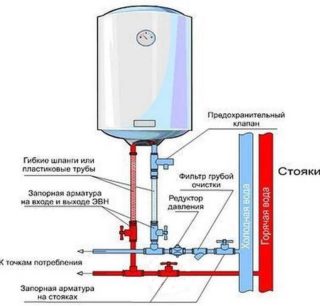

Valve installation and adjustment

The non-return valve is attached to the cold water pipe. For the convenience of work, manufacturers mark it in blue. The crane can be screwed on at any stage of installation, but it is advisable to do this until the tank is hung on hooks. When the heater is on the floor, working with it is much easier, more convenient and safer.

Installation should be carried out in the following sequence:

- Unscrew the fixing bolts and remove the plastic cover. So that it does not interfere with the work, you do not need to remove the light bulb from it, and then remove it to a safe place.

- Inspect the thread on the inlet of the tank, visually check its integrity. Clean the coils with a brush, remove the transport grease with a dry cloth.

- Carry out a similar procedure with the upper flare nut of the valve. If there are burrs, they must be carefully removed with a knife or file.

- Wind the FUM tape onto the nozzle. This should be done clockwise, shifting the thickening to the side. The layer thickness should be 1 mm at the cut and 3 mm at the beginning of the thread.

- Take the valve, catch the edge of the thread and start screwing it. The product should go tight and with effort. It is important that at the end of rotation the nut does not rest against the rim. This will mean that insufficient FUM tape was wound. The procedure will have to be repeated.

After fixing the safety valve, you can immediately attach a ball valve to it. The procedure is carried out similarly.

Causes of breakdown of the safety valve

If the valve on the boiler drips constantly, regardless of the time of day or the intensity of water use in the house, there is a high probability that the product is malfunctioning. There can be many prerequisites for this.

- Manufacturing defects. As a rule, these are weak springs and leaking cylinders. Such products will work even with a working pressure. Faced with such a nuisance is that it seeks to save and buys cheap Chinese fakes.

- Clogging. Occurs when the tank is improperly cleaned or due to poor water quality. The essence of the breakdown is that after compression, the spring cannot be unclenched, since interference from solid particles forms on its path. With such a malfunction, the product will leak even with the device turned off and the tap turned off.

- High system pressure. It is not uncommon on the upper floors of high-rise skyscrapers. Since the pressure is maintained at a constantly high level, the valve will flow continuously, regardless of the time of day.

- Mechanical damage. Occurs during transportation or during installation.It is possible to damage the internal parts during cleaning - deformation of the spring, rupture of the gaskets. When falling, a gap appears at the entrance of the pipe into the boiler body.

- Leakage of the storage tank. In such cases, water is observed outside the product, but it may seem that a valve is flowing on the water heater. The cause of the leak is corrosion or a dilapidated seam.

- The upper part is leaking. There is a weak connection. This is one of the most common causes of droplets on the valve. In most cases, this occurs due to the hardened gasket under the nut or an insufficient amount of FUM tape.

- Spring wear. Over time, they lose their elasticity and begin to shrink even with a slight pressure. Nothing will help here. It remains only to put a temporary drainage and go to the store for a new valve.

If a leak has formed, by itself it will not disappear anywhere. The situation will only worsen until it reaches a critical state. Therefore, if a safety valve flows on the boiler, urgent measures must be taken to find out the causes of this phenomenon and restore the functionality of the water heater.

Breakdown Work

In order to diagnose and fix the breakdown, you need to stock up with a set of tools and some consumables.

To work, you will need:

- adjustable spanner, pliers, screwdriver;

- scissors;

- awl;

- indicator;

- FUM tape or tow;

- flexible hoses for convenient drainage of water from the tank;

- lemon acid;

- box for collecting small parts;

- rags.

Measures should be taken to protect the limbs and organs of vision. Repair is best done with safety glasses and gloves.

First you need to make sure that the check valve is the cause of leakage. It is enough to check whether his case is dry or not. If there is no moisture on it, then you need to start disassembling. This event can be timed to coincide with the cleaning of the Tena and the descaling tank. In any case, the forces will not be wasted.

Dismantling should be carried out in the following order:

- Block the water. If a faucet is installed in front of the mixer, it is better to do it by turning, so as not to turn off the entire apartment.

- Disconnect the appliance from electricity. Remove the cover, disconnect the wires from the terminals.

- Unscrew underwater pipes from the boiler. Remove ball valve and safety valve.

- Screw flexible hoses to the nozzles, water will go in the right direction.

- If there is a pressure gauge, check the working pressure of the water. Ideally, it should be 1.5-2 atm.

- While the fluid is draining, remove the remaining FUM tape and inspect the parts for cracks and dents.

- Clean the tank and TEN from limescale and scale. Rinse the container inside with a shower head.

The removed check valve must first be rinsed under running water to remove scaly fragments. After that, the product should be immersed in a container with a solution prepared from water and citric acid in a ratio of 10: 1. You can speed up the cleaning process by boiling. 10-15 minutes are enough for the valve to become like new. It remains to treat it with silicone grease and can be put back.

Boiler life extension

The main enemies of the boiler and non-return valve are impurities in the water and high pressure in the pipeline. These problems are solved by installing an input main magnesium filter and a special gearbox. If this does not work out, depending on the degree of hardness of the water, it is necessary to carry out preventive cleaning of the boiler and its fittings every 3-9 months.

In order to prevent a strong expansion of the water in the tank, it is recommended to heat it to a temperature of no higher than + 55 ° C.