The operation of the heating system must be not only effective, but also reliable. To ensure this, it is necessary to choose the right installation scheme, components and consumables. According to the rules, the final measure of installation or commissioning is testing of heating systems: hydraulic, thermal, pneumatic.

Test assignment for heating

Inspection should be an obligatory measure, since during this hidden and obvious defects can be revealed. But how to conduct a thermal or hydraulic test of a heating system? To do this, refer to the regulatory document SNiP3.05.01-85.

It does not describe a clear methodology for performing these procedures. However, there is a link to GOST 25136-82, which describes the recommendations on the preparation of the act of hydraulic testing of the internal heating system. These activities must be carried out both for stand-alone circuits and for district heating. They are intended for the following:

- Preliminary check of all circuit elements before starting. Minimizing the probability of failure of individual nodes;

- Monitoring the compliance of the finished system with the design parameters - temperature conditions, pressure and heat load;

- In some cases, it is necessary to show representatives of government agencies the act of testing the thermal effect of heating systems or another document confirming the fact of verification.

There is a certain procedure, according to which the sequence of tests is established. So, first, an act of hydraulic testing of the internal heating system is drawn up, which can be replaced by pneumatic (bubble). The final protocol is a thermal study of the operation of the heating system.

Before proceeding with heating tests, a preliminary calculation of the system must be performed. This is the only way to determine the optimal pressure indicators, which is important for further crimping the system.

Hydraulic heating test

In fact, this procedure is filling the system for leak testing. In contrast to testing heating systems with air, the hydraulic effect shows how ready the equipment and components are for the winter season.

To conduct a hydraulic test of the heating system, the following conditions must be met:

- Ambient temperature should be more than + 5 ° С;

- The connection unit of pumping equipment for filling the system is located in the lowest part of the circuit - in the return pipe;

- If the pipes are closed in some areas of heating, the protective panels should be temporarily removed to visually control the filling of the system.

In the central heating system, a hydraulic check is carried out 1.5-2 months before the start of the heating season. In the supply unit of a multi-storey building, collectors are opened through which the pipeline is filled. Pressure adjustment is done using the elevator unit. The final stage of the test is a completed act of hydraulic inspection of the internal heating system.

Only representatives of the management company should be involved in the execution of tests and the preparation of the certificate. But tenants have the right to demand a copy of the document.

Pneumatic heating test

In some cases, it is not possible to comply with the basic conditions for conducting a hydraulic test of the heating system. A similar situation may arise after repair work is carried out in the winter, when the ambient temperature is below + 5 ° C. Then you should draw up an act of pneumatic testing of the heating system.

Its essence is to create a pressure of 100 kPa in the heating mains. Moreover, within 10 minutes, the level of its decrease should not exceed 10 kPa. To verify this, use pressure gauges with an accuracy class of 2.5 and a division value of not more than 5 kPa. All characteristics of the equipment may be present in the act of pneumatic testing of the heating system.

For polymer pipelines, such checks are not recommended. However, the norms allow testing of heating systems with air from polypropylene or plastic in the following cases:

- Specifications do not allow fluid filling. Most often this is due to the use of antifreeze;

- Ambient temperature below 0;

- Temporarily there is no coolant in the required volume.

The main problem when testing the system by air is the search for places of loss of tightness. If during the procedure a sharp decrease in pressure was noticed - it is recommended to perform a zone check of the sites. This is the only way to determine the place of a possible leak. Therefore, they prefer the hydraulic method, as more convenient.

At the end, draws up an act of pneumatic testing of the heating system, into which the results are entered.

For the correct preparation of the act, it is recommended to fill out the forms of the accepted form. They can be taken at the office of the management company or on its website.

Heat test

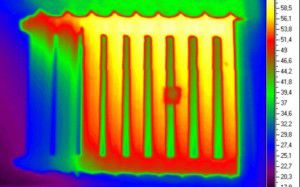

Timely thermal testing of heating systems will determine the uniformity of heating of all radiators and batteries. Unlike the above documents, this procedure is recommended to be performed without fail for autonomous schemes.

For central heating, these activities are not performed every year. The act of thermal testing of the heating system is drawn up only in the following cases:

- Putting the system into operation;

- Replacing most of the components with new ones, changing the configuration of pipelines.

Testing the heating system for warm-up is often combined with a trial run before the heating period. To do this, it is not enough to fill the pipelines with coolant and turn on the boiler. First, clean the system, saving it from accumulated debris and limescale. If this is not done, thermal tests of the heating system will be incorrect. Foreign elements will affect the thermal conductivity of radiators and pipes, which will directly affect their energy output.

It is best to combine hydraulic and thermal testing. In this way, air jams can be prevented.

Central heating

For a centralized scheme, filling out the act of testing the thermal effect of heating systems is performed according to certain rules. The main one is the temperature of the water - it should be heated to + 60 ° C.

The time of the inspection should be at least 7 hours. At the same time, individual components are adjusted for temperature balancing of the nodes. This is reflected in the act of thermal testing of the heating system. In apartment buildings, for each riser, separate measurements are made and general indicators are compared with those in the elevator unit.

What are the benefits for the residents of the house when heating systems are tested for heating?

- Verification of actual heat supply indicators with those declared by the management company;

- With an installed metering device and adjusting the flow of coolant (in the elevator unit) - the ability to determine the optimal mode of operation of the system;

- Timely identification of air jams.

All these works must be performed by the management company. This is displayed in the heat supply contract. The result of the test will be an act of testing the thermal effect of the central heating system.

The act of thermal testing of the heating system takes into account not only the degree of heating of radiators and pipes, but also the temperature in the room.

Heating system

Testing an autonomous heating system for heating is also necessary. During this procedure, you can pre-determine the point of a sharp temperature drop. Using the control valves, the radiator and battery modes are set.

In practice, for stand-alone circuits, it is not necessary to draw up an act of testing the thermal effect of heating. But to determine the course of action, it is best to adopt a methodology for central heating. The difference may lie in the measurement methods:

- The degree of heating of the heating elements is checked by installed thermometers or according to the readings of the thermal imager;

- The room temperature is monitored using external sensors.

However, in the summer, the effect of low outside temperatures will not be taken into account. Therefore, in addition to the above indicators, it is necessary to take into account the degree of thermal insulation of the house - heat loss.

Remember that each type of test of heating systems (hydraulic, thermal or pneumatic) must be performed according to a specific method. It also depends on the type of heating system and external factors.

The video material describes the features of a hydraulic heating test in an apartment: