Having decided on the project of the house, the developer proceeds to the choice of building material for the construction of walls. Polystyrene blocks relatively recently began to be actively used in low-rise construction, although they have been present on the market for more than two decades. The reason is the conservatism of the industry and distrust of the foam used as a filler. Work with building materials implies knowledge of its features and rules of use.

What is polystyrene concrete

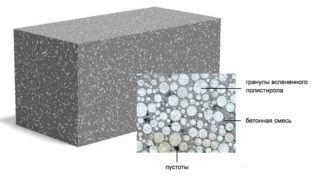

The building material under consideration belongs to a particularly lightweight class of concrete with a porous structure made on a cement binder and aggregate made of polystyrene foam granules.

Depending on the grade of strength, the ratio of components varies. Washed river sand or quartz from quarries is introduced into the composition of products for laying bearing walls.

Scope of application

Products must comply with GOST R 51263-2012. “Polystyrene concrete. Technical conditions. "

The document defines the technical characteristics and methods of application of monolithic or prefabricated products.

The main directions of use:

- the construction of load-bearing walls in low-rise construction;

- insulation of external walls;

- thermal insulation of floors and floors with plates or by screed pouring;

- production of jumpers for window and doorways;

- construction of interior partitions.

When building walls, the brand of strength of the blocks must be taken into account.

Material properties

In the construction of residential and utility buildings, the characteristics and consumer properties of materials are important.

In the construction of residential and utility buildings, the characteristics and consumer properties of materials are important.

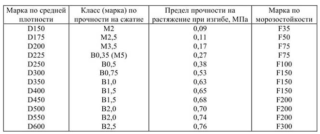

Technical parameters of finished products:

- density grade - from D150 to D600;

- compressive strength class - from M2 to B2.5;

- frost resistance grade - F35 – F300;

- thermal conductivity coefficient - 0.052–0.14 W / (m * оС).

Blocks reach full strength 28 days after manufacture.

Positive features and disadvantages

Twenty years of experience proved the positive qualities of plastic blocks:

- reduction of heating costs due to low thermal conductivity;

- fire safety;

- soundproof ability;

- environmental friendliness;

- the material does not rot and does not support the spread of the fungus;

- blocks with cladding do not require finishing;

- high construction speed due to the large size of prefabricated parts.

The identified shortcomings of polystyrene concrete are mainly associated with improper selection of building materials based on strength - the walls do not withstand the load, shrink, cracks appear. The same problems are inherent with improper manufacturing techniques.

Blocks are susceptible to destruction during frequent freeze-thaw cycles.

For fastening to walls of heavy structures, it is necessary to use specialized hardware.

Varieties of polystyrene concrete

A positive result of the construction and durability of the construction directly depends on the correct choice of materials.

GOST identifies four varieties of products.

Heat insulating polystyrene concrete is produced with an average density of D150 - D225 and compressive strength not lower than M2. Plates are used for warming load-bearing walls, ceilings over cold driveways and basements. Liquid polystyrene concrete is poured in the form of a screed on the floor.

Thermal insulation construction the variety should be in density D250 –D350 and correspond to a compressive strength class of at least B0.5. Blocks, lintels, additional elements are used for insulation of load-bearing walls or the construction of non-load-bearing structures.Abrasive jumpers are cast from polystyrene concrete.

Of cross void elements build fixed formwork, which is filled with reinforced concrete, receiving monolithic walls.

Thermal insulation concrete is produced with a density of D400 - D600 and compressive strength not lower than B1.5. Blocks are made from it for the bearing walls of one- or two-story buildings, and are used to make jumpers.

Sizes of finished products

GOST does not establish the exact geometric dimensions of polystyrene concrete products for manufacturers.

The sizes recommended by the document are collected in a table.

| Product Type | Length mm | Width mm | Height / thickness mm |

| Polystyrene concrete slabs | 1000–2000 | 500–600 | 50–200 |

| Ordinary wall blocks | 590–1200 | 250–400 | 295–400 |

| Additional elements | 145–1200 | 250–400 | 60–200 |

| Polystyrene concrete lintels | 1190–2998 | 180–300 | 115–180 |

| Sill blocks | 595–1200 | 295–400 | 250–400 |

In the product line there are wall half-blocks.

When designing and at the stage of pouring the foundation, it is important to know exactly what size products the plant produces at the construction site.

Manufacturing methods

Expanded polystyrene blocks are purchased at the factory or made independently.

The first method is preferable, since the manufacturer has the ability to accurately comply with the recipe of the mixture. After buying building materials, you can immediately begin construction.

With self-production, it will be necessary to withstand 28 days before the start of masonry for a full set of strength blocks.

In factory and home conditions, polystyrene blocks are made in two ways: injection molding and vibropressing.

Injection method

The casting method produces products of low and medium strength, suitable only for the construction of non-bearing insulating walls.

As a filler, GOST allows the use of recycled polystyrene raw materials. To obtain it, polystyrene is grinded in special machines.

The mixture for structural heat-insulating blocks may include only polystyrene in granules. Secondary raw materials in these cases are prohibited.

Further, the manufacturing algorithm is as follows:

- Polystyrene granules, water, a plasticizer (latex) are fed into the mixer, mixed for two minutes.

- Cement is introduced into the mixture, without turning off the mixer, it is continuously mixed for 3 minutes.

- If necessary, add sand in the desired proportion.

- Forms are prepared by lubricating their inside with machine oil.

- After thorough mixing, the solution is poured into molds.

- After 2-3 days in the summer or 5-7 days in the winter, the molds are freed from the frozen blocks - formwork is carried out.

- In some industries, drying is carried out in autoclaves.

- Leave the finished product for a set of strength.

The proportions of the ingredients for concrete of different densities are collected in a table.

| Density, kg / m3 | Cement kg | Water, l | Expanded polystyrene, m3 | Latex kg |

| 200 | 200 | 100 | 0,84 | 2 |

| 250 | 250 | 120 | 0,84 | 3 |

| 300 | 300 | 150 | 0,84 | 3,5 |

Making polystyrene concrete with your own hands, you need to stock up with the necessary number of forms for blocks and jumpers. To gain strength, you must have a sufficient amount of free space, protected from precipitation.

Vibrocompression

The second method, which can be applied in production and in everyday life, is more productive. High-density “bricks” are obtained by vibropressing, which can be used for the construction of load-bearing walls.

The second method, which can be applied in production and in everyday life, is more productive. High-density “bricks” are obtained by vibropressing, which can be used for the construction of load-bearing walls.

Work Stages:

- Preparation of raw materials, measuring the number of components.

- Mixing of components in a concrete mixer.

- Pressing on vibrating machines.

- Drying in the drying chamber at the factory or under shelter from rain and sunlight at home.

The method differs in the proportion of components. For strength, quartz or washed river sand is added to the composition of block polystyrene.

The table shows the formulations for concrete per 1 cubic meter of finished products.

| Strength grade | Portland cement, kg | Sand kg | Polystyrene, kg / m3 | Latex, l | Water, l |

| D300 | 160 | 75 | 9 | 3,5 | 95 |

| D400 | 190 | 110 | 10 | 4 | 115 |

| D500 | 215 | 180 | 11 | 5 | 130 |

Recipes are characterized by a low water content, the mixture is thick.Casting of such a composition is impossible. To eliminate air voids and pressing is used.

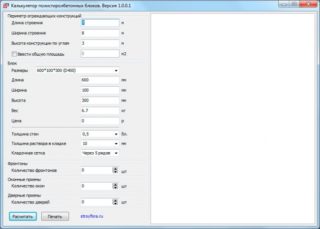

Calculation of the number of blocks

It is not difficult to calculate the required amount for building a house of blocks, knowing the size of the building.

Calculation Sequence:

- The perimeter of the building is calculated.

- Multiply the length of the perimeter by height, obtaining the total area of the walls.

- Multiplying the length and height of the block, get its area.

- Dividing the area of the walls by the area of one structural element, they will find out the number of products necessary for the construction.

- The supplier’s price lists always indicate the number of blocks in 1 m3. The figure can be obtained independently by dividing 1 m3 by the volume of the element. For example, one standard unit with dimensions of 598x298x200 mm occupies a volume of 0.0356 m3. Therefore, in 1m3 of such blocks there will be 1 / 0,0356 = 28 pieces.

Some publications recommend subtracting the dimensions of door and window openings from the wall area. This should not be done, as the resulting "savings" will be used for dressing in the corners of the building.

Features of masonry and decoration

For masonry use special glue. It has high thermal insulation properties and increased adhesion. In addition, the glue is very plastic and allows to achieve a joint thickness of 3-5 mm.

Seams close up with the same composition that was used for masonry.

The adhesives quickly set, so at the same time knead as much solution as needed for 15-20 minutes of work. Correcting the position of the block in the masonry is allowed within 10-15 minutes, after this time you will have to remove the solution and re-lay the masonry.

Every 3-4 rows, a steel reinforcing mesh is laid, which will help to avoid cracks in the walls during shrinkage.

Finishing is carried out 3-4 months after the end of the masonry, until this point, shrinkage occurs.

Walls inside and out are subject to obligatory protection - plastering, covering with siding and other means. The blocks are hygroscopic, mechanical impacts leave dents on the surface. Under the influence of precipitation and sunlight, polystyrene concrete is gradually destroyed.

During further operation, one should take into account the difficulties with hanging household appliances and furniture on the wall. One attachment point cannot be loaded above 20 kg. Select dowels with a length of at least 60 mm and a diameter of 6 mm. The holes for fasteners are drilled 1-2 mm less than the diameter of the dowel, since polystyrene concrete is subject to mechanical compression.

For plastering, you should choose specialized mixtures, do not use sand-cement compounds. It is important to pay attention to the compatibility of building and finishing materials, to use special primers and adhesives.

The right choice of polystyrene blocks and finishing materials allows you to build a reliable, warm home. Working with blocks is easy, the precise geometric shape makes it easy to get smooth walls.