When creating a heating system, much attention is paid to the choice of fuel. Many are considering the option of biological raw materials, which include pellets. This is a waste of woodworking production, which are specially treated. To switch to heating with pellets, you need to familiarize yourself with their properties, characteristics and advantages. Such heating is used in the country, in private homes.

Description of raw materials

Pellets are wood pellets treated with a special material. In fact, they represent waste from woodworking production. Pellets are environmentally friendly natural raw materials, which do not contain hazardous chemicals and compounds. They are non-toxic and safe for health and the environment.

The best raw materials for the manufacture of pellets are sawdust, cuts, shavings, slabs, wood flour and other waste. Granules can be white, black, gray depending on the type of wood. Farmers can create pellets from hay, husks of sunflower, reeds, rice husks and other agricultural waste. Their processing does not cause difficulties and does not require special equipment. Pellets can also be made from peat. This is a more costly process, as it requires the availability of special equipment and good resources.

The main parameters include:

- Ash content. The lower it is, the better for the boiler - it does not require frequent cleaning.

- Humidity. The amount of water in the pellets is about 60.

- The total length of the granules.

- Density.

- The bulk mass.

- Abrasion class.

Properties also depend on the rock from which the fuel is made.

Manufacturing technology

The main point of production is to dry and extract wood waste to a specific fraction under a pressure of 300 atmospheres. The use of glue and other bonding additives is prohibited.

The following equipment is required for production:

- Crushers. Allow to grind raw materials to a certain fraction.

- Dryer. Reduces moisture to a predetermined level.

- Hammer mills, chip machines or disintegrators. Allow to obtain fractions up to 4 mm in size.

- Screw mixers.

- The press.

Production Stages:

- Drying the rock to a certain percentage of moisture. The value is predefined. High-quality fuel contains a minimum of fluid, making home heating more efficient.

- Shredding. The raw material is sent to the crusher, where it is crushed to a predetermined fraction.

- Pressing. Pellets are sent to a pellet mill, which collects them into pellets. This process is also called pelletization. For pressing, special dies and molds are used.

- Cooling.

- Packing and shipping to the consumer.

Also before grinding can be carried out regrinding and water treatment. It depends on the type and quality of the raw materials.

When the cooling process is completed, the fine particles are sieved and sent for recycling. This allows you to make production virtually waste-free.

On average, the production of one ton of pellets requires about three to five cubic meters of wood. Compaction occurs three times. The preparation of one ton of fuel will require about 30-50 kW / h of energy.

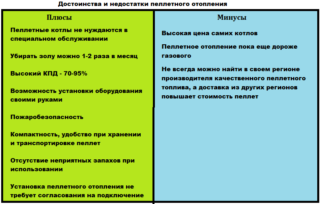

The benefits of pellets

Fuel features can improve the heating process, making it more efficient.

Fuel features can improve the heating process, making it more efficient.

The positive qualities of raw materials include:

- Environmental friendliness. Pellets are made from natural materials, so they are safe for the environment and human health.

- Cost.Pellets are more expensive than firewood, but their price is lower than other types of fuel.

- Low ash content. During the season, the average ash formation is 20 kg.

- The possibility of recycling ash.

- Simplicity and convenience of storage.

- High efficiency of the installation operating from pellets. High thermal conductivity.

- No combustion control required.

- Depending on the model of the furnace, the fuel supply may be enough for the whole season.

Of the shortcomings, only a higher price is allocated than for firewood. Machinery operating from this type of raw material requires more complex maintenance, which increases the cost of use.

Unlike firewood

Both types of fuel are produced from the same materials. But their combustion process is different. This is due to the fact that the firewood is more humid, which is why part of the energy goes to the evaporation of moisture. Only after this occurs combustion. Also included is ash, which is non-combustible ash. Pellets consist of the same parts, but in different proportions. There is about 5% of water in them, so less time will be required for evaporation, all the energy will be spent on heating.

The density of pellets is higher than that of firewood. For this reason, they are required in less quantity for heating. When 1600 kg of wood is burned, the same heat is released as when using 1000 kg of pellets.

Fuel consumption

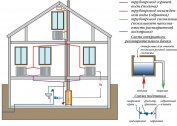

Raw materials are sold in bags with a specific volume. This allows you to simplify the calculation of the required number of pellets per 1 sq.m. and 1 kW of energy. Pellet heating can be correctly calculated in several steps, as a result of which the user will receive monthly fuel waste for heating and will be able to find out the average cost.

First you need to find out how much heat gives 1 kg of granules. Part of the energy is sent to the chimney pipe. As a result, the heat of combustion of the particles is multiplied by the efficiency of the generator.

To generate 1 kW of energy, a certain amount of fuel is needed. To do this, divide 1 kW by the obtained value of the amount of heat.

On average, for heating a house with an area of 100 sq.m. it takes about 5 kW of energy per hour. The heat consumption per day is 5 kW * 24 h = 120 kW. For a month you get 120 kW * 30 days = 3600 kW. This value is multiplied by the calorific value and the weight of the pellets to be used for the month is obtained.

From these values you can find out the daily consumption and other values for any area.

Features of pellet boilers

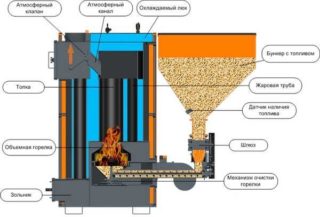

Pellet boilers are characterized by high efficiency and high cost. The design of such a device has the following components:

- Compartment. Granules for heating are stacked in it. It can be built-in and external.

- Pellet feed mechanism. Screw and pneumatic systems are used.

- Automatic ignition module. Allocate lambda probes, control systems on a local line, GSM, monitoring via the Internet.

- Burner. There are different types - flare, mantel, volumetric combustion. Differ in principle of action, shape and temperature.

- Sensor Management Module. Sensors are responsible for maintaining the temperature regime.

Due to the presence of thoughtful and high-quality automation, pellet boilers are also popular. This allows them to be conveniently operated without the need for constant monitoring.

Features of the device directly depend on the quality of the granules. When buying cheap fuel, there is a risk of deterioration in the functioning of the boiler. The technique depends on electrical energy, failures of which also lead to difficulties in operation. The average life is 20 years or more.

The main disadvantage of pellet boilers is the high cost of equipment and maintenance.

Recommendations of specialists

If you want to buy a pellet boiler, you should study the opinion of professionals. Quality devices are ways to heat and provide hot water to an entire building.

Key tips:

- The boiler requires periodic cleaning, otherwise its effectiveness is reduced. It is also important to pour granules into the hopper in time and check the draft in the chimney.

- Pellets are stored in a dry room in a house or surface building.

- When choosing a fuel, you need to pay attention to size. Average length does not exceed 50 mm, diameter about 6 mm. Elements should be smooth.

- When making fuel yourself, you should know in advance on what equipment it can be made. Rice husk requires serious costs and effort due to the presence of silicon in the composition, which leads to rapid wear of equipment.

- A quality pellet boiler requires financial costs. Its price cannot be low due to materials and manufacturing technology. It is important to buy equipment in a specialized store and choose the equipment of well-known trusted brands.

There are pellet fireplaces. In such a device, a fire-resistant protective glass is used, which prevents the fire from entering the room. The selection criteria are the same as for the boiler, plus the style of the device itself.