The company "Vesuvius" produces heating devices made of cast iron for 10 years. Each plate is designed on the principle of forced convection of air and its rapid heating. Vesuvius stoves are designed for heating baths, greenhouses, workshops and small houses. The lineup is reliable and low cost.

Hardware Specifications

The stove from the Vesuvius brand is distinguished by a system of pipes relating to the sections of the furnace. They are placed so that when sucked from the floor, the cold air masses rise up and heat up. The manufacturer produces products with the following characteristics:

- wall thickness depending on the zone of the furnace - from 8 to 12 mm;

- air heating - from 60 to 150 degrees;

- long burning - from 7 to 8 hours after heating;

- performance - a small unit is able to pass 4.5 m3 of air per minute;

- different volume of the steam room - from 6 to 50 m3;

- the volume of the combustion chamber is from 14 to 30 m2;

- maximum temperature of the product - 1200 degrees;

- standard chimney diameter - 115 mm;

- the depth of the furnace tunnel is 290 mm.

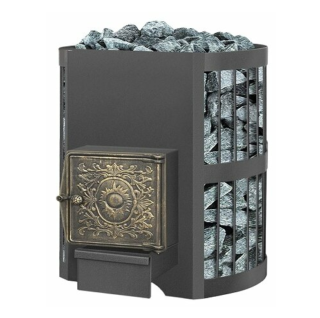

Models have a rounded shape, which contributes to an even distribution of heat throughout the room. The all-welded outer casing of the plates is bolted together. For high-quality heating of stones, an external mesh or door is used. The manufacturer's warranty on the entire range of furnaces is 35 years.

Using the Vesuvius stove you can heat the room up to 350 m2.

Benefits of Vesuvius Furnaces

The Vesuvius furnace is safe due to bolt or welding fastening of parts. The joints of the elements of the furnaces are processed using a ceramic seam, which allows to withstand high temperatures without damage. Universal equipment, which has many advantages, is equipped with a Russian bathhouse or Finnish sauna.

Durability

Cast iron is a material that does not deform at high temperature, so the equipment has been in operation for more than 30 years. Solid rectangular grates are nearby and do not crack when heated. The stove is not subject to corrosion, therefore, does not require heat-resistant staining or anti-corrosion treatment.

Versatility

The owner of a bath, sauna, greenhouse or workshop can install a stove with good heat dissipation. The equipment is easy to operate, capacious firebox for firewood. For baths, a closed type of heater is suitable for generating wet steam.

A water tank is not supplied with the furnace, but the manufacturer proposes to purchase a 55-125 liter Vesuvius boiler.

Cooking Ability

For a summer residence or a country house of temporary residence, you can not purchase cooking equipment. For cooking, the upper horizontal surface of the unit is suitable. The only condition is the use of the right utensils. Pig-iron utensils are compatible with stoves, which warms up evenly, preserves the taste of products and keeps them warm for several hours.

For equipment with a small volume of the furnace during cooking, it is necessary to reduce traction.

Efficiency & Cost Efficiency

Forced convection technology provides quick room heating. Due to the channel system, air exchange is accelerated - the heater is able to work in rooms with a volume of 100-150 cubic meters.

The stone container can hold up to 60 kg. The material is placed in the compartment between the casing and the furnace, heats up to 400 degrees and gives good steam.The blower and the working area have a special configuration - the device runs for 2-3 hours after one fuel tab.

The blower is made as a pipe embedded in the loading hatch, due to which a single-door system is realized. This allows you to quickly light the furnace and clean the ash.

The organosilicon protection of the case excludes its deformation and rusting under the influence of moisture, high temperature.

Only firewood, bark, wood chips and wood shavings can be laid in the firebox. When using coal, the body overheats, the welded joints crack.

Easy installation

A cast-iron stove for a Vesuvius bath is sold in a complete assembly; it is simply placed indoors. To organize a fireplace in a workshop or a country house, the products are bricked up, leaving holes on the side to remove warm air. Before installing the device, a chimney is equipped.

If the stove is used as a heating unit, it is necessary to completely change the piping system in the house.

Manufacturer lineup

The company "Vesuvius" produces several types of wood stoves.

Potbelly stove

The stove-potbelly stove from the Vesuvius brand is made in the Mini modification, intended for installation in a small room - a garage, a greenhouse, an attic. For the manufacture of the unit, structural steel 5 mm thick is used.

Benefits:

- beautiful details;

- convenient handle;

- it warms up small rooms up to 100 m3;

- welded joints are invisible.

Minuses:

- there are no holes in the cellar;

- it is made without grid-irons;

- no drawer or door for ash cleaning.

Product weight - 20 kg, height - 450 mm, width - 300 mm, depth - 500 mm.

Fireplace stove

The Vesuvius fireplace stove is produced in several versions.

In line Scythian includes 26 devices that differ in size. The furnace body is welded, the firebox has a remote construct, the ash pan extends. The ventilation hood is made in the form of a mesh.

Features of a series:

- heating of rooms with a volume of 6-40 cubic meters;

- the ability to bookmark up to 60 kg of stones;

- door decoration (panoramic, heat-resistant glass);

- large capacity of the ventilation casing - stones heat up to 350 degrees;

- prolonged heat storage.

The location of the stones in the casing around the perimeter of the furnace eliminates the influence of infrared rays on the metal.

Fireplace PC manufactured by Vesuvius in angular and direct modifications. Direct models include:

- PK-03 (224) - is equipped with a cast-iron cooktop, fire-resistant heat-resistant door, thin lining. After the first bookmark, firewood burns up to 5 hours. Equipment power - 12 kW.

- PK-02 (205) - is made with a hob, a system for adjusting the intensity of combustion. The stove is decorated with ceramic inserts. You can connect an electric fan to it. Power equals 12 kW.

- PK-01 (270) - a steel fireplace unit with a heat-resistant door. At the bottom of the furnace there are 3 cast iron grate. Using the blower, you can adjust the combustion modes. The power of the device is 9 kW.

Corner models are represented by a series of PK-01 (220). The wood-burning fireplace is made of steel with talchochlorite lining (beige, red, marbled). The height of the furnace is 843 mm, the width is 752 mm, the depth is 586 mm. Power is 9 kW.

Fireplaces are made under a chimney with a diameter of 115 mm.

Sauna stoves

The Vesuvius brand oven, which is suitable for a bath or sauna, is also available in several series.

Series Legend - An open heater that weighs almost 160 kg. It is equipped with an extended firebox, which is suitable for heating rooms up to 28 m3. The devices are compatible with chimneys 115 mm in diameter, can be installed in steam rooms for 8-30 cubic meters.

Differences of the line:

- heating stone mass weighing 210 kg from all sides;

- integrated converter housing;

- the possibility of heating from the steam room, adjacent room;

- firebox of 3 elements.

Legend is the fastest unit in the brand line.

Series Hurricane different forged parts.Models 12 (260), 28 (270), 16 (205) and 28 (224) differ only in size. Drown from the steam room, adjacent premises. Units are designed for a steam room of 6-30 cubic meters.

Differences of the line:

- firebox of 3 elements;

- ceramic joint at the junction;

- working temperature - 1200 degrees;

- closed-type heater;

- malleable convection-ventilated casing.

Modification The standard is equipped with a leaky door DT-3.

Several modifications of the series Sensation which are heated from a steam room or an adjacent room. Ventilated stove is designed for granite rocks weighing 60 kg.

Features of a series:

- quick heating of stones up to 350 degrees;

- stability of temperature and steam production;

- removable outer casing;

- complete with cast-iron door.

The Sensation line is designed for Finnish (dry), Russian (wet and steam), Turkish (steam bath).

Budget line Optimum with a firebox 30x20 cm is made of metal 5 mm thick. The mesh-shaped casing holds 110 kg of stones. It is produced in two models with different types of use of the furnace (steam room, adjacent room).

The differences of the series:

- heating the steam room with a volume of 6-14 squares;

- cast iron grate;

- cast pattern on the door;

- scapular ashpit.

The height of the furnace is 58 cm, the width is 50 cm, the depth is 56 cm.

Series Lava and Rusich - stoves that are installed in a bath or sauna. Are made with a cylindrical or rectangular casing. The rulers are similar in design:

- Rusich - modifications designed for 40 kg of stones give light and dry steam. The rectangular firebox is reinforced at the top, rear (8 mm) and side (6 mm). The temperature of the stones rises gradually, without overheating. The steam room can be used in the Hammam mode.

- Lava - available with fireproof glazed doors. Traction adjustment is carried out using the damper. The weight of the stones for the bookmark is 50 kg.

The Rusich series includes 20 models, the Lava series - 23.

- Lava

- Solid fuel boiler

Features of the Triumph furnace

The Triumph line is made of cast iron. Model 180 T / O has a water circuit and a heat exchanger, model 180 - is available without it. Units are installed in rooms up to 180 m3.

Features of a series:

- equipment weight - 98 kg;

- the width of the furnaces is 485 mm, the height is 615 mm, the depth is 505 mm;

- bolted connection of elements;

- processing joints with a ceramic cord;

- two cast-iron elements 1 mm thick near the firebox;

- fire chamber with a door made of refractory glass;

- presence of adjustment of the intensity of combustion.

The operational period of the Triumph series is more than 30 years.

Mounting Features

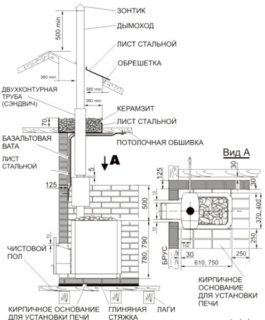

The brand recommends involving specialists in the installation of equipment. If the owners have skills or tools, self-installation is allowed. The process is as follows:

- Laying a red brick base to a height of 6 mm or a refractory foundation of 20 cm thick material.

- Removing the product from the wall from the tree by 50 cm.

- Sheathing the wall with a metal sheet. In this case, the distance is reduced to 38 cm.

- Execution of a superstructure in half a brick with preliminary cutting of the wire frame of the furnace.

Walls can be covered with slab brick pharmacies.

The manufacturer's instructions note the specifics of installing a specific modification of the furnace.

Legend Series

Installation work involves the assembly of the chimney, taking into account the location of the rafters and load-bearing beams:

- Sectional ceiling installation. A hole 130 mm in diameter is made along the axis of the chimney with an angle of inclination along the roof angle.

- Fixing on the outlet pipe of a single-circuit, starting pipe or tank with a gap seal.

- Installation of further elements - tapped with a mallet or hammer through the boards.

- Mounting the throttle and putting a chimney on it. Passing through the opening of the starting sandwich and organizing the coupling support clamp.

- Laying heat-resistant heat-insulating material - basalt wool, mineral wool.

- Further assembly of the chimney using sandwich elements along the condensate line.

- Putting on the chimney clamp cone with further tightening.

- Installation of the last sandwich and closing it with an umbrella-tip.

After checking the strength, tightness of joints and traction, a test firebox is produced.

Sauna stoves

The equipment is located in the steam room, and the tank is in the sink. For convenience, a samovar-type heat exchanger that heats the water is used. This increases the efficiency of the device, eliminates the removal of heat through the pipe.

Installation of fireplaces

Units are installed in rooms with good air flow. The optimum height of the smoke channels is 600 cm. The pedestal is made of non-combustible materials. To remove ash, an inflow zone from a sheet of metal 40 cm in front of the furnace and 10 cm on each side is organized. The distance from the fireplace to the ceiling is from 1.2 m.

The range of Vesuvius furnaces provides high-quality heating of the bath, it is characterized by efficiency and economy. The manufacturer produces cast iron models designed for a long service life.