One of the solutions to the problem of heating a house can be pyrolysis solid fuel heating boilers - efficient in operation and unpretentious in operation. However, the high cost of factory-made heating devices makes a potential buyer think: rather than try to make a pyrolysis boiler yourself? For a working person with technical skills, this is quite possible. Our article will help to understand how the combustion process occurs in a pyrolysis boiler for heating a private house, from what materials it can be mounted and how to connect it to the heating system.

Features of pyrolysis heating devices

The main difference between a pyrolysis solid fuel heating boiler (gas generator) is considered to be the special principle of fuel combustion. If in ordinary boilers firewood or coal simply burn with an open flame, then the process is divided into two stages:

- Fuel is loaded into the combustion chamber and a fire is kindled. When the temperature exceeds 400 ° C, the pyrolysis process begins - slow decay of the fuel with a lack of oxygen. This generates heat, smoke and pyrolysis gas, which includes carbon monoxide and various hydrocarbons.

- To put the boiler into operation, close the direct draft damper and turn on the fan. The gaseous products of pyrolysis are displaced by a stream of primary air into the combustion chamber, where they are enriched with oxygen from the supply of heated secondary air. The mixture of pyrolysis gases and suspended particles completely burns out and gives off its thermal energy to the heat exchanger built into the boiler.

How economical and convenient are pyrolysis heating boilers, user reviews confirm. Now they no longer need to get up at night to toss firewood. The next portion of fuel loaded into the boiler will slowly smolder from evening to late morning. The combustion efficiency is such that almost no ash remains, and only a light transparent smoke comes from the chimney.

For the normal course of the pyrolysis process, the boiler must be equipped with a fan, so it is necessary that the power supply in the house is uninterrupted.

Requirements for homemade pyrolysis boilers

In order for a self-made pyrolysis heating boiler to surpass the efficiency of a conventional solid fuel boiler, its design must meet strict requirements:

- the temperature in the furnace should be optimal (600–700 ° C), since it is under these conditions that the most high-quality isolation of pyrolysis products occurs;

- regulation of combustion power should not significantly reduce efficiency;

- the heating boiler must be suitable for continuous continuous burning of fuel;

- the housing of the pyrolysis gas combustion chamber must be resistant to corrosion and able to withstand temperatures above 1200 ° C.

It is also desirable that a chamber for pre-drying wood raw materials be provided in the boiler design.

Specifications that a home-made pyrolysis boiler should have for heating a private house:

| Technical specifications

|

Units rev. | For small houses

|

For cottages |

| Power | kW | 15–25 | 35–50 |

| Efficiency | % | 80 | 85 |

| Maximum working pressure | bar | 1,8–2,0 | 3,0–4,5 |

| Max. heating area | m² | up to 200 | up to 500 |

| The volume of water in the heat exchanger | l | 18–25 | 40–65 |

| Furnace volume | l | 70–100 | 200–300 |

The use of a home-made heating device is sometimes risky, because with an improperly regulated combustion process, so-called “cotton” can occur - an explosion of pyrolysis gas.

Fuel for pyrolysis boilers

Of all fuels, firewood and various wood waste are better suited for the pyrolysis process. In addition, in pyrolysis boilers for heating a private house, you can also burn coal or peat, but the efficiency will be slightly less.

The thickness of the logs does not matter much, and their length is limited only by the dimensions of the combustion chamber. The main condition is that among them rot and trash should not come across. If, in addition to firewood, sawdust and shavings be used for burning, their volume should not exceed 1/3 of the total fuel load.

Wood fuel should be dry, humidity not more than 20-25%. Otherwise, its combustion will be incomplete, heat transfer will decrease, and the chimney will become clogged with soot and tar.

DIY pyrolysis boiler

To make tosolid fuel pyrolysis calving, an amateur craftsman will first have to study the available information on this issue.

Within the framework of our article, we are able to give only general recommendations, and detailed drawings can be searched on the Internet. It is also useful to look at forums where experts exchange opinions.

According to their reviews, do-it-yourself pyrolysis heating boilers will still be cheaper than buying branded ones.

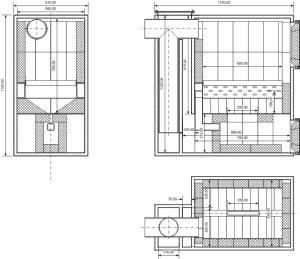

The power of the pyrolysis boiler is determined by several factors, and the main ones are: the overall dimensions of the product, the volume of the combustion chamber and the height of the primary air supply.

Any ready-made scheme of a heating system with a pyrolysis boiler will need to be modified taking into account the specific conditions of your home.

Materials and manufacturing technology

To make a pyrolysis heating boiler with your own hands, you will need:

- electric welding machine and a good supply of electrodes;

- "Grinder" and at least 20 cutting wheels to it;

- steel 4mm, 3 sheets 1.25 × 2.5 m;

- steel 2 mm, one sheet;

- pipe 57 mm with a total length of 8 m;

- fireclay brick, 12-14 pcs.;

- and some more small details.

Cutting metal and performing welding is not an easy task. If there is no way to do this yourself, you will have to invite a wizard.

The boiler doors must be closed tightly so that heat is not lost and smoke does not come out.

Testing the finished boiler

During the test, the shortcomings of the home-made heating boiler should be identified and methods for their elimination determined. A qualitatively mounted pyrolysis unit has the following properties:

- fuel flames up quite easily with natural traction;

- smoke does not escape from under the seal of the upper door;

- the fan provides a stable air flow and does not make noise;

- the boiler enters the operating mode in 20-30 minutes;

- when the fan is turned on, the flame in the combustion chamber is strong and even;

- the pyrolysis gas combustion process is manageable;

- when the fan stops, the reverse thrust effect does not occur;

- the ratio of thermal power to the spent amount of firewood corresponds to the calculations.

If a home-made heating boiler demonstrates compliance with these parameters, it can be considered functional after eliminating the discovered deficiencies.

Schemes for connecting a pyrolysis boiler to heating

The heat in the house depends on whether the heating system with the pyrolysis boiler is properly arranged and whether the furnace mode complies with the norm. All the nuances need to be provided for at the design stage.Heating a house can be done using hot water or air.

When developing a heating system, special recommendations and safety standards must be strictly followed.

Water heating

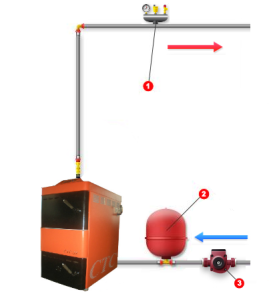

The installation of a pyrolysis solid fuel heating boiler should be carried out in a room specially designated for the boiler room. In addition to the boiler itself, it is necessary to place here such elements of the heating system as a circulation pump, shut-off valves, expansion tank, sensors, thermometers and other devices. In the same boiler room, it makes sense to equip a place for logs of firewood near the boiler so that you do not often have to go out in the cold.

Direct connection of the pyrolysis boiler to the heating system can be performed in different ways. The following figure shows the easiest way to connect.

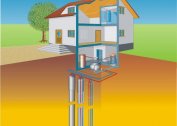

Other ways to connect the pyrolysis boiler to a water heating system:

- with a contour of a mix - to the above system elements are added an additional circuit and taps that control the amount of heated water;

- with a hydro arrow - this scheme is best manifested in heating systems with several circuits;

- with storage tank - the water is heated by entering it from the tank and allows optimizing the operation of the boiler even without electricity.

When choosing a connection scheme for the pyrolysis boiler heating system, it is advisable to calculate the cost of each option in order to find the best among them.

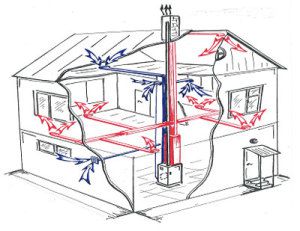

Air heating

Homeowners use a pyrolysis air heating boiler most often not for heating a house, but for garages, warehouses, greenhouses and other utility rooms. The method of heating living rooms with heated air has not yet become widespread. But here, the use of a pyrolysis boiler could demonstrate its advantages. For example, an air heating system is especially relevant when the owners of a country house are concerned that the water heating system does not unfreeze during their long absence.

A system using pyrolysis air heating boilers consists of one or more fans, temperature sensors, a control unit and a duct network for transporting hot air to the heating points.

Whichever heating system pyrolysis solid fuel boilers are used for, for their trouble-free operation, it is necessary to insulate the chimney so that condensation does not form on its walls.

Finally

By analyzing reviews of pyrolysis heating boilers, you can get the impression of their undoubted advantages. In the context of the gradual rise in price of natural gas, it is increasingly becoming justified to decide to arrange a heating system with a pyrolysis boiler of hand-made manufacture. Many users are attracted by the autonomy of such a system and the simplicity of its operation.

Watch the video on how to make a fairly simple model of a pyrolysis boiler with your own hands:

For those who cannot connect to the central gas supply, pyrolysis solid fuel heating boilers will become reliable assistants in the heating of housing. But if you decide to save, then your decision will be to make a heating device yourself. Installation and connection of the pyrolysis boiler to the heating system will be accessible to people with engineering and locksmith skills.