The technology for designing and installing a heating system in a wooden house differs from standard schemes. This is due to the material of the building and its performance. Therefore, it is necessary to take into account the features of the heating system in a wooden house: the arrangement of pipes, the choice of boilers and stoves.

Rules for organizing heating in a wooden house

A professional installation of heating in a wooden house begins with the choice of a scheme and its adaptation to the parameters of a particular building. It is mandatory to pay attention to the specifics of the structure.

The main selection criterion is the safety of the heating system. Correct wiring of heating pipes in a wooden house should not impair the quality of the building, as well as lead to dangerous situations.

To avoid this, the following important points are taken into account when designing and installing heat supply:

- Mounting expansion joints and sliding mounts. The average shrinkage of the log house can be 5%. In this case, the position of the pipes and radiators will change. Therefore, the scheme of heating systems of a wooden house should be adapted to this phenomenon;

- Installation of bushings. Contact of pipes and batteries with a wooden surface is strictly prohibited. This can lead to zonal expansion and deformation of the walls and floor. Heating pipes in a wooden floor should be carried out through the logs using special steel sleeves;

- Installation of a safe chimney. The temperature of volatile combustion products can reach + 700 ° C. The correct calculation of heating in a wooden house should take into account the corresponding insulation of the chimney in places of contact with the wall or when passing through the floor floors.

Experts recommend that you familiarize yourself with the current SNiPs, with which you can make safe and efficient heating in a wooden house with your own hands. The main ones for studying are SNiP 41.01-2003, SanPiN 2.1.2.1002-00 and SNiP 23.01-99. They set out the requirements for thermal insulation of a house, the choice of heating systems and the optimal parameters of its operation - temperature, pressure and thermal distribution.

Heating radiators for a wooden house are no different from standard ones. It is important to choose the right installation diagram to prevent direct contact of the heater with a wall or floor.

Parameters for choosing heating in a wooden house

In a wooden house you can use all types of heat supply. But first, you need to analyze all the factors that influence the choice. Often, heating options for a wooden house directly depend on several of them.

The primary task is to determine the optimal energy source. It can be solid fuel, gas, electricity or diesel. It all depends on the cost and the possibility of constant supply.

You can not do the installation of heating in a wooden house with your own hands without the following preliminary stages of analysis:

- Fuel selection;

- Heat Generation Equipment: boiler, convector (gas, electric), film heating;

- Development of a layout of heaters. The heat distribution throughout the house will depend on this;

- Analysis of fixed costs for heat supply. The best option is gas heating in a wooden house. But this takes into account the difficult preparatory stage of obtaining permits.

If there is a connection to the gas line, the choice stops on this type of fuel. If it is possible to purchase cheap (and high-quality) diesel fuel, they make water heating of a wooden house with a boiler (or burner) of this type. The total area of the building and the degree of its insulation are also taken into account.

In practice, the choice of heating options for a wooden house depends on financial capabilities. Therefore, you should first draw up the optimal budget for the organization of heat supply in the building.

Gas heating in a wooden house

Installation of any gas-fired heating equipment should only be carried out by specialists. This is especially true for the arrangement of heat supply in wooden houses. There are several ways to implement gas heating in a wooden house.

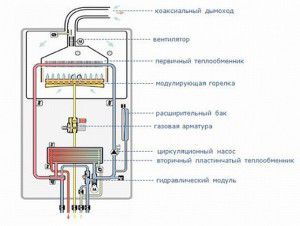

The most common heating method is to install batteries and radiators. They are connected to a gas boiler. There are two types of equipment, depending on the type of fuel used:

- Using trunk (natural) gas. To install heating in a wooden house, you must connect to the gas main. For this, a project is drawn up, the basis of which is the terms of reference from the management company;

- Application beam (liquefied) gas. For storage use special cylinders with a capacity of 10 to 50 liters. It is possible to minimize the costs of storage and delivery of fuel by installing a special storage facility - a gas tank.

In a typical scheme of heating a wooden house with gas, installation of pipelines that connect to the batteries is provided. However, recently the floor heating system has gained great popularity. In this case, heating pipes are installed in the wooden floor. This scheme is characterized by a greater length of highways as a result - increased heat transfer.

In buildings with a small area, you can consider installing gas convectors. In this case, there is no need to make the heating pipes in a wooden house, install radiators and boilers. The main source of heat is a gas type convector.

It is installed in every room of the house. To connect the gas, it is necessary to make a supply line.

The following factors are the features of installing heating in a wooden house with your own hands:

- Coaxial pipe installation is done only with a safety sleeve. It protects the exterior walls of the house from temperature effects;

- To ensure safety, the correct material for the manufacture of pipelines should be selected. They must be designed to transport gas;

- Heat exchange in a room can be improved with a fan installed next to the convector. There are currently models that come with a fan.

The main advantage of DIY heating in a wooden house is the ease of installation and maintenance. But compared with a gas boiler, fuel consumption will be 20-25% higher.

When calculating heating in a wooden house, it is recommended to organize the storage of gas cylinders in steel cabinets. Arrangement of a separate room will require large expenditures and time.

Solid fuel boiler in the heating of a wooden house

The rules for the design and installation of solid fuel water heating of a wooden house are practically no different from gas. Exceptions are recommendations for the arrangement of the boiler room. The large dimensions of solid fuel boilers and the heating of their surface cause special requirements for the boiler room.

Before installing heat supply in a wooden house with your own hands, you need to familiarize yourself with the characteristics of this room:

- Minimum area The boiler room should be 7 m². This is necessary for repair and maintenance work;

- Non-combustible materials. The boiler must not be installed on a wooden floor. As protection, you can use a sheet of stainless metal;

- Forced ventilation. The cross section of the ventilation duct is calculated from the ratio of 8 cm² per 1 kW of boiler power;

- Natural and artificial lighting;

- Minimum chimney height - 5 m. The number of bends should not exceed 3.

All heating batteries for a wooden house are mounted according to the rules. The minimum distance from the walls should be 3 cm. It is recommended to install a foam sheet to reflect heat on the wall.

Without fail, the installation of protective components - an air vent, a drain valve, an expansion tank, is provided for in the schemes of the heat supply systems of a wooden house.

Electric heating of a wooden house

It is not always possible to install a solid fuel boiler or connect to a gas main. In this case, choose electric heating of the wooden house. To do this, you can install water heating with an electric boiler or consider a more economical option - film heating.

In this case, you do not need to install heating batteries for a wooden house. In film heating, objects, not air, are heated. Conductive carbon strips are applied to the polymer surface.

With the passage of electric current, radiation is generated with a wavelength of 10-15 microns. When it hits the surface of objects, an increase in temperature occurs.

The main advantages of film electric heating of a wooden house are:

- Economical power consumption. This is due to the rated power PLEN up to 200 W / m²;

- Low inertia. Unlike gas heating in a wooden house, the temperature rises quickly. However, after the first installation, the system must first stabilize;

- The small area occupied by the PLEN. This is true for the electric heat supply of country wooden houses or cottages;

- Does not affect the humidity indicator in the house. To maintain the optimal microclimate in the rooms, this option for heating a wooden building is considered the most optimal.

However, for PLEN it is necessary to ensure uninterrupted power supply. In the event of a power outage, it will not work. Therefore, PLENs are often made as an alternative system along with water heating for a wooden house.

For the normal operation of the film heating, the total film coating area should be from 70% or more relative to the area of the ceiling or floor.

Stove and air heating in the house

Despite all the advantages of the above methods of heating the air in the log houses, furnace heating is still relevant. It is distinguished by a high laboriousness indicator when installing heating in a wooden house, as well as a low efficiency value.

To install this type of heat supply, a separate foundation will be needed. It is best to erect it at the construction stage of the building. If you plan to install a steel (cast-iron) furnace - you can not do it. A significant drawback of stove heating in a wooden house, made by yourself, is the small heating area. To solve this problem, you can think of a hot air circulation system in all rooms or make air heating in a wooden house.

A special heat exchanger is installed in the stove or fireplace, in which air is heated. He enters the premises of the building through pipelines. Most often, the mains are located on the ceiling, but installation options for the heat supply pipe in a wooden floor are possible. It all depends on the design of the furnace.

Features of air stove heating in a wooden house:

- Protection of the floor and walls in the area where the oven is installed;

- It is recommended that you install a fireplace or stove in the center of the house so that the heat from it is evenly distributed throughout the premises;

- Before installing a steel structure, it is recommended that the base be made of concrete screed or brick.

Instead of heating radiators for a wooden house in the air system, grilles with shutters are used. By changing the angle of the slats, you can adjust the amount of inflow of hot air into the room. To minimize losses during the advancement of air masses, the distribution of heat supply pipes in a wooden house is done with a minimum of turning parts.

To store firewood or coal, it is necessary to use a separate room or building. Fuel should not be in the same room as the stove.

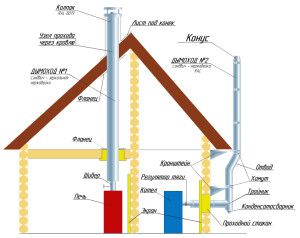

Chimneys in a wooden house

Particular attention in the design of heat supply should be given to the exhaust system. This function is performed by the chimney, which runs from the boiler (furnace) to the roof.

To calculate the chimney parameters, you need to know the approximate temperature of carbon monoxide. It is not constant and varies depending on the type of fuel used and the design of the boiler.

For stoves and solid fuel boilers, it is recommended to use brick chimneys or sandwich pipes. If you plan gas heating in a wooden house - you can install a coaxial chimney. But in any case, it is necessary to insulate the structure to prevent condensation. Most often, basalt or mineral wool is used for this.

| Type of boiler (stove, fireplace) | Carbon monoxide temperature, + ° С |

| Stove, fireplace. Fuel - firewood | 350-650 |

| Bath stove | 400-700 |

| Pyrolysis boiler | 160-250 |

| Pellet boiler | 120-250 |

| Diesel fuel boiler | 150-250 |

| Gas boiler | 120-200 |

| Solid fuel boiler | 500-700 |

When installing the chimney system yourself, you should be guided by the following rules:

- For brick chimneys, a separate foundation is most often needed. The thickness of the seam should not exceed 10 mm;

- The minimum distance from the chimney to the wooden wall is 25 cm;

- Forced ventilation is installed in the room;

- When the chimney passes through the floors, installation sleeves are installed. To compensate for thermal radiation, there should be a layer of asbestos between them and the wooden surfaces;

- The height of the pipe above the roof should be 500 mm;

- The minimum thickness of stainless steel chimneys is 1 mm.

To improve traction, a deflector is installed. In addition to preventing precipitation from entering the chimney, it helps to stabilize the movement of air, which is important for the normal operation of the boiler or furnace. For stove heating, you can make a wall of brick, which equip chimneys of complex shape. This contributes to better heating of the wooden house and increases the heating efficiency.

The video shows an example of heating a wooden house with a boiler: