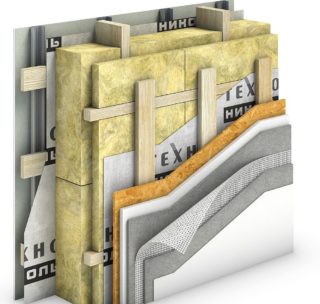

Frameworks are considered one of the most popular today. They are economical, light in weight, the construction technology is simple and understandable. However, to ensure the optimal microclimate inside the building, the walls lack thickness.

External heat insulation will allow increasing thermal protection, in addition, competent thermal insulation of a house, in addition to a comfortable stay, increases the life of the building. How to insulate a frame house from the outside? What is needed for cladding the facade, which technology to choose?

Varieties of materials and tools

For warming frame buildings are used:

For warming frame buildings are used:

- The cellulose insulation of ecowool, which does not burn, does not decay, insects and rodents do not start in it. It has high sound and heat insulation performance, while being environmentally friendly. To install ecowool, you will need special equipment, it is almost impossible to do external insulation with it with your own hands. This is not the most economical option to improve the performance of a frame building, however, one of the most reliable, easy to install.

- Hemp or linen hemp mats are ideal for frame buildings. Their capillary structure is similar to wood. Good moisture absorption. With external insulation of the frame structure with linen or hemp mats, vapor barrier is not needed. Instead, a vapor-permeable membrane is sufficient.

- Straw, sawdust with good sound, heat-absorbing properties, environmental friendliness, durability, affordable.

- Mineral wool, non-combustible, vapor-proof material. It costs more than polystyrene foam, but it attracts by its long service life and is easy to operate. The only drawback is hygroscopicity, which will require additional arrangement of vapor barrier.

- Polyfoam, expanded polystyrene - a popular option for insulation. The laying method is simple, affordable, the panels have good moisture and air tightness.

- To warm the frame house, you can also use peat, an environmentally friendly non-combustible material resistant to decay with high moisture-absorbing characteristics.

You will need tools:

- Electric drill, hacksaw, screwdriver;

- Level, construction knife, several spatulas, including with a serrated edge;

- Hammer, construction level, glue;

- The reinforced grid with a cell of 50 mm, expansion bolt shields with an umbrella or mushroom head, screws, nails;

- Wooden bars for lathing with a width equal to the width of the selected material.

Insulation procedure

In general terms, the work order looks like this:

In general terms, the work order looks like this:

- Preparation of the outer surface.

- Arrangement of vapor barrier.

- Installation of insulation.

- Finishing work.

The first stage of the work on the sheathing of the frame structure outside is preparatory. The surface of the walls, supporting structures are cleaned of dirt, dust, removing wire, nails, adhering particles. If the surface of the facade is uneven, there are cracks, it is worthwhile to first level it with the plastering method.

This will ensure maximum tightness of the contact of thermal insulation and the outer plane of the walls. For better adhesion, the surface is primed, while the primer consumption per 1 m 2 is 150 ml. After the soil dries, proceed to the installation of insulation.

Technology

Polystyrene foam. After preparatory work, proceed to the installation of insulation. First, an adhesive is prepared, diluting it so that it lasts about an hour. It is applied in the corners and in the center of the plate, after which the cogs are evenly distributed along the perimeter with a spatula. The foam is pressed firmly against the wall, starting laying from the bottom. Avoid distortions will help the level cord with sag.When the foam does not fit together, it is trimmed with a construction knife with a heated blade. Docking slots close up with mounting foam or adhesive solution with polystyrene foam crumbs. After gluing the material to the walls, it is fixed with umbrella plastic dowels at the rate of 5 pcs. on 1 plate. Then, a reinforcing mesh is mounted on the plane for subsequent puttying, reinforcing the corners with special corner profiles. Prepared plane

Polystyrene foam. After preparatory work, proceed to the installation of insulation. First, an adhesive is prepared, diluting it so that it lasts about an hour. It is applied in the corners and in the center of the plate, after which the cogs are evenly distributed along the perimeter with a spatula. The foam is pressed firmly against the wall, starting laying from the bottom. Avoid distortions will help the level cord with sag.When the foam does not fit together, it is trimmed with a construction knife with a heated blade. Docking slots close up with mounting foam or adhesive solution with polystyrene foam crumbs. After gluing the material to the walls, it is fixed with umbrella plastic dowels at the rate of 5 pcs. on 1 plate. Then, a reinforcing mesh is mounted on the plane for subsequent puttying, reinforcing the corners with special corner profiles. Prepared plane  putty in 2 layers, after drying, the wall is primed, covered with paint and other finishes.

putty in 2 layers, after drying, the wall is primed, covered with paint and other finishes.

Ecowool. In addition to excellent operational characteristics, it is good in that when laying it forms an even, seamless canvas. The easiest way in this case is to install insulation between the racks with an additional arrangement of wind protection, for example, from hydrophobized plates. The process looks like this. First, install the crate, while the inside of the structure should be covered with kraft paper, reinforced with foam. After that, holes are made in the canvas, a hose is inserted and ecowool is blown out, controlling the blowing density. The surface outside should be flat, so the irregularities are cut with a construction knife. Typically, ecowool dries in 2-3 days, after which they begin to finish.

Mineral wool. The process consists of several stages. Initially, the plane is prepared, treated with waterproofing mastic. After that, from the bars treated with an antiseptic, a crate is constructed. The step between them should be equal to the width of the insulation, minus 2-3 cm on each side for a snug fit of the plates with each other. The first row of bars and the counter-rail are mounted vertically, if the insulation is 2-layer, the bars of the second row of crates are mounted horizontally. When the frame is ready, the voids are filled with mineral wool, on top for wind protection they are lined with a film, fixing it with counter-rails. Now the facade of the frame building is ready for further siding. An important point: the arrangement of ventilation. To do this, gaps are left at the bottom and top of the wall, or grates are mounted in the siding panel. If it is decided to leave gaps, they are pre-covered with a fine mesh to protect the frame building from insects and rodents.

Mineral wool. The process consists of several stages. Initially, the plane is prepared, treated with waterproofing mastic. After that, from the bars treated with an antiseptic, a crate is constructed. The step between them should be equal to the width of the insulation, minus 2-3 cm on each side for a snug fit of the plates with each other. The first row of bars and the counter-rail are mounted vertically, if the insulation is 2-layer, the bars of the second row of crates are mounted horizontally. When the frame is ready, the voids are filled with mineral wool, on top for wind protection they are lined with a film, fixing it with counter-rails. Now the facade of the frame building is ready for further siding. An important point: the arrangement of ventilation. To do this, gaps are left at the bottom and top of the wall, or grates are mounted in the siding panel. If it is decided to leave gaps, they are pre-covered with a fine mesh to protect the frame building from insects and rodents.

In kind materials. Insulation of the facade from the outside can be done using straw, sawdust. In addition, you need to get a shovel, a bowl for mixing the mixture, a watering can. Boric acid, cement and lime are also needed. The minimum thickness of the insulating layer should be 0.3 cm. Electrical wiring, switches, sockets, sections where the chimney passes are protected by refractory membranes. For cables, for example, metal pipes with a wall thickness of 3 mm can be used. First, cement, lime, sawdust or straw are placed in the container, mixed thoroughly. After this, boric acid is diluted in a watering can, straw, sawdust are sprayed with a solution. Wet heat-insulating mixture is placed in areas that need thermal insulation, then straw, sawdust is well compacted, left to dry. If necessary, re-fill the mixture of sawdust, lime and cement. This may be necessary if voids are found in the heat-insulating layer after drying.

In kind materials. Insulation of the facade from the outside can be done using straw, sawdust. In addition, you need to get a shovel, a bowl for mixing the mixture, a watering can. Boric acid, cement and lime are also needed. The minimum thickness of the insulating layer should be 0.3 cm. Electrical wiring, switches, sockets, sections where the chimney passes are protected by refractory membranes. For cables, for example, metal pipes with a wall thickness of 3 mm can be used. First, cement, lime, sawdust or straw are placed in the container, mixed thoroughly. After this, boric acid is diluted in a watering can, straw, sawdust are sprayed with a solution. Wet heat-insulating mixture is placed in areas that need thermal insulation, then straw, sawdust is well compacted, left to dry. If necessary, re-fill the mixture of sawdust, lime and cement. This may be necessary if voids are found in the heat-insulating layer after drying.

Useful Tips

If the siding will be installed vertically, the battens of the battens are mounted horizontally. If the sheathing goes vertically, then the bars are mounted horizontally.

If the siding will be installed vertically, the battens of the battens are mounted horizontally. If the sheathing goes vertically, then the bars are mounted horizontally.

For the arrangement of thermal insulation, it is better to use not rolled, but plate materials.

To eliminate the appearance of cold bridges will help the installation of layer-by-layer installation of a lap insulation with a width of 50 mm.

Thermal insulation materials are selected based on the climate zone. The optimal thickness of the insulation is 100-250 mm, the minimum is 30 mm.

If it is decided to use sawdust, straw, they are first allowed to mature for 2 months. If you need to speed up the process, the raw materials can be moistened with liquid glass.

If sawdust, straw is used, metal pipes with walls of at least 3 mm are mounted in the layer during insulation. In this case, you do not have to arrange a vapor barrier, the mixture of sawdust and cement will completely absorb excess moisture.

When installing linen or hemp mats, the frame racks are installed at a distance from each other, the step should be 2-3 cm wider than the insulation.

Most insulation technologies for frame buildings are simple and straightforward. But if there is any doubt that it will be possible to accomplish everything exactly according to the technology, it is worth using the services of masters, having paid for the work.