The choice of solid fuel boilers as the main source of thermal energy is due to several factors. One of them is the affordable cost of fuel. But along with this, inconvenience in maintenance is noted - it is necessary to constantly fill the furnace, remove ash, etc. Therefore, as the best alternative, they choose home heating with pellets: boilers, consumption, reviews of which talk about the advantages over conventional systems.

Features of pellet heating at home

First you need to understand the difference between pellets and simple wood. For the production of granules, wood waste is used that goes through several stages of processing. After thorough drying and cleaning, they are exposed to steam, resulting in a viscous mass. Then, under a pressure of 300 atm, small cylindrical granules from 6 to 8 mm in diameter and up to 70 mm in length are obtained.

A modern pellet heating boiler can generate more heat than a similar one on wood. This can be seen from the comparison table of the calorific value for different types of fuel.

| Fuel | Calorific value, kW / kg |

| Firewood | 2,84 |

| Fuel briquettes | 4,7 |

| Pellets | 4,99 |

But even this is not an advantage of heating pellets at home. The task of constantly filling the combustion chamber with fuel was solved in a rather effective way. In general, the heating system consists of several blocks:

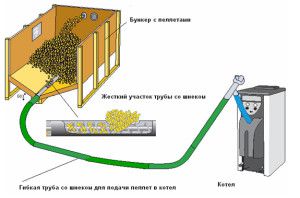

- Bunker. Designed for storing pellets. Often made of stainless steel. An important parameter is its volume. Depending on this, a further maximum fuel supply is determined;

- Pellet feed line to the boiler. Consists of a flexible hose and auger. Under their own weight, the granules enter the screw rotor and from there into the distribution chamber;

- Modern pellet boilers for heating a house are divided into several zones. In the first, granules are loaded, which, through the bell, fall into the zone of influence of the air burner. In this case, incomplete combustion of the fuel occurs, resulting in the formation of wood gas. It is the main source of heat, burning in the afterburner.

With this heating scheme, the operation of the boiler is almost completely automated. It is only necessary once every 3-4 days, with continuous operation, remove the ash and replenish the hopper with fuel as necessary.

The rules for installing the boiler on pellets for heating a private house are the same as for other similar equipment. Therefore, it is best to equip a boiler room for this, which will meet the requirements of SP 42-101-2003.

Pellet boiler selection

Without a properly selected boiler, it is impossible to heat the house with pellets. Reviews about various models are not always unambiguous. Someone does not like the relatively low efficiency, some complain about the constant clogging of the combustion chamber. Therefore, when choosing equipment, it is recommended to pay attention not only to its power, but also to design features.

The ratio of the generated thermal energy to the area of the house for pellet equipment is standard - 1 kW per 10 m² of living space. Then you need to pay attention to the following functional and design features of the boiler:

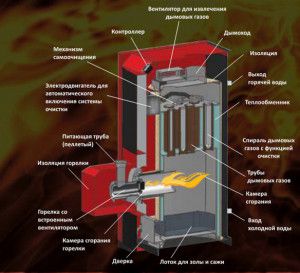

- Combustion chamber volume. The maximum load of the furnace and the burn-out time of all fuel depend on this;

- Self-cleaning function. Pellet heating boilers have a flue gas spiral.Over time, a soot layer may form on it, which will significantly reduce the power of the equipment;

- Automatic control. It is best to choose models with the ability to control the load depending on external factors - temperature in the room, on the street, etc. In this case, the pellet consumption for heating will be optimized.

For consumers, the main indicator is still the cost of the boiler. Among the many models, there are several that are used for heating on pellets. Reviews of their work indicate reliability and a good indicator of efficiency. One of the most affordable is the products of the Russian company Teplodar. Their model Kupper OK 20 currently costs about 84 thousand rubles. The kit includes a hopper, feed device, burner and the boiler itself.

In the industrial segment of powerful heating equipment, Viesmann leads the way. Their automated kit, designed for a maximum power of 90 kW, costs about 310 thousand rubles.

In addition to power, you need to pay attention to the efficiency of the boiler. Efficient heating of the house with pellets is possible with a minimum rate of 80% or higher.

Quality pellets for heating

However, in addition to correctly selected equipment, the operation of pellet boilers for heating a house directly depends on the quality of the fuel. The popularity of this method of heating the room has led to the appearance of low-quality granules made by handicraft method without observing technology. This was reflected in the actual calorific value - it is significantly below normal. There is an erroneous opinion that the consumption of pellets for heating in a private house depends on their color. In fact, the darker the granules, the more bark was used to produce them. Light yellow pellets are made from furniture industry waste, and dark brown pellets are made from logging. Also, all types of granules will sink in water, since their density exceeds 1.

One of the main selection criteria is ash. According to existing European standards, this figure should not exceed 1.5%. In case of inconsistency during combustion, a large amount of slag will form, which will negatively affect the operation of the boiler.

In addition, quality pellets should have the following characteristics:

- Humidity - less than 10%. Otherwise, there will be an increase in pellet consumption for heating due to loss of heat capacity;

- Dust content - not more than 11%. This directly affects the ash content of pellets;

- Packaging. The best option is when the granules are stored in special bags processed inside with a waterproofing film. In this case, their storage period may be calculated in years.

The cost of one kilogram of granules is from 6 to 10 rubles. depending on the package. If you have a large hopper, it is recommended to purchase pellets in the so-called big bags - large bags. The mass of full containers will be about 900 kg.

Reviews on pellet heating can be found on specialized forums. Comments on sellers or manufacturers' websites are not always objective due to internal moderation.

How to determine pellet consumption

Another correct question that arises for future owners of the above equipment is how much pellets are needed to heat a house? To determine this indicator, you need to know the main flow factors.

The main one is the area of the house. With the proper level of thermal insulation for heating 1 m² of the room, 200 grams of pellets for heating in a private house will be consumed. This is an indicative indicator, depending on the model of the boiler and its parameters.

In addition, when calculating the flow rate, such characteristics must be taken into account.

Pellet boiler power selection

Ideally, it should correspond to a ratio of 10 m² of space 1 kW of energy.However, in this case, the equipment will operate at maximum load. Therefore, you need to take a small margin of power. Then for a building with an area of 200 m² you will need the following number of pellets for heating a house - (200/10) * 0.2 = 4 kg per hour at maximum load.

Automatic fuel system

It is necessary to install such a fuel supply mechanism in order to create economical heating of a private house with pellets. Reviews about homemade augers and flow control devices are generally not very good - it is difficult or impossible to make fine adjustments to the supply of pellets to the boiler. Therefore, it is recommended to purchase factory models.

Climate zone

For winters with a low minimum temperature, pellet consumption will be correspondingly less than with extremely low frosts. This is also necessarily taken into account when calculating the consumption of pellets for heating in the house.

In the presence of a gas main, it is best to choose this type of energy carrier. According to reviews, heating on pellets is economical, but still more expensive than gas.

Self-made heating pellets

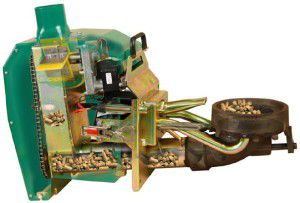

Is it possible to make heating a house with pellets in such a way as to minimize material costs? In some cases, a standard solid fuel boiler is upgraded.

To do this, you need to purchase a pellet burner and a screw for feeding granules. When using big bag bags, you can make a suspension system that replaces the hopper. The flexible PVC hose must have a diameter of 75 to 100 mm. This takes into account that the screw will be mounted inside it. The latter is best purchased factory, as it will already have an electric motor for rotation.

The burner also needs a factory one, since self-production may cause problems with reliability and power regulation. The average cost of 30 kW of the model will be from 45 to 50 thousand rubles. The main problem will arise when operating an old boiler. It does not provide a cleaning system, as in special models. Therefore, it will be necessary to clean the heat exchanger of soot once every 2-3 months.

Is it profitable to use a pellet heating boiler? Yes, but it’s best to choose boiler models that can work not only on pallets, but also on any other solid fuel. Some of them are designed even for the installation of a gas or diesel burner. This will make it possible to change the type of fuel without upgrading the entire system.

As an example of the complexity of the independent manufacture of a pellet burner, you can watch the video material: