No one argues that it is wonderful to have your own "house in the village." However, with the onset of cold weather, the problem of heating such a house arises sharply. Since, as a rule, there is no centralized heating similar to what exists in urban apartment buildings in rural areas, it is necessary to solve the problem of installing a brick furnace for water heating. Its arrangement is not so complicated, but the heat energy obtained is very cheap, and the stove itself has a high efficiency of about 80-85%, so double heating of the house per day is enough. Heated heating radiators slowly give up the stored heat - for several hours. At this time, the furnace can not be heated, but the house will still be warm, even if it is very cold outside. A small-sized heating water boiler is able to provide a fairly large area of housing with heat (for small houses, just a stove is enough). The heating of the boiler itself is achieved due to the hot smoke from the furnace.

Essential tool

Before starting work, you need to stock up on the tool:

Before starting work, you need to stock up on the tool:

- a pickaxe for breaking bricks into small components, necessary when laying out the details of the furnace;

- the construction level necessary to control the evenness of the masonry;

- Large shank shovel for mixing masonry mortar;

- steel trowel-trowel for coating the furnace with clay or cement and leveling this mixture on the surface, as well as sealing joints between bricks;

- wooden ruler to check the evenness of the corners of the furnace.

Masonry order

When laying the furnace, it must be strictly monitored so that the bricks do not touch the boiler, and also leave a small gap for its expansion when heated.

When laying the furnace, it must be strictly monitored so that the bricks do not touch the boiler, and also leave a small gap for its expansion when heated.

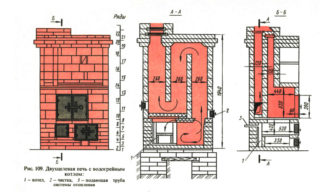

The lowest row of bricks is laid out by the method of continuous well masonry, while on one side a couple of bricks are squeezed, thus forming a bias towards the bottom of the furnace. The next row of bricks is interspersed with longitudinal jumpers (dressings), and a blower is mounted on the third row. The fourth row should also contain a hole in the wall of the furnace for further cleaning. In the same place, from a piece of brick, they establish a similarity of a support under a cast-iron or steel headset for a firebox in the form of a grate to maintain solid fuel in the furnace (grates).

The ash from the burnt fuel will spill out through the slots of the grate; therefore, holes and doors for cleaning are provided on the next row of masonry. A heating water boiler is also mounted at the same level, its crown must reach the outlet of the pipe for supplying hot water. This installation scheme prevents air from entering and stagnating in the furnace heating system. On the next row, again, jumpers are needed at the joints of bricks, they immediately put a door for the furnace. 7 row is laid in the usual way, but the next one is laid out so that the chimneys are completely covered with bricks. The next 3-4 rows are laid with longitudinal jumpers.

Rows 13 and 14 are the ceiling of the heating chamber, so they are made of fireproof material. Rows 15 to 17 complete the heating chamber equipment. On the 17th row, several more holes are made with doors for cleaning. By the next row, the horizontal surface of the furnace ends. From the 20th row, a chimney begins to be outlined, which is arranged in order with horizontal jumpers at the joints and ends on the 30th row. The upper wall of the furnace, overlapping the flue gas duct, is carried out on the 38th row of masonry, and a smoke valve is installed in the same place.

It is very important to lay out the chimney correctly - this is a difficult and very crucial stage.It is necessary to make sure that the internal walls of the house (especially the wooden one) are at least half a meter from the chimney, this is dictated by fire safety measures.

Experts recommend laying a chimney made of refractory bricks with a section in the form of a square with a side length of about 40 cm, the inner square - an opening with a side size of half a normal brick. Outside the roof of the building, it is possible to use a conventional pipe, which will speed up and reduce the cost of arranging a water heating furnace. One of the modern options is ceramic pipes made of refractory clay-kaolin (chamotte). They are reliably protected from ignition of unburned fuel particles and temperature differences, they last a very long time and have high corrosion resistance. Their shell is made of concrete or stainless steel, which makes the design of the entire furnace very reliable.

To protect against spontaneous fires, it is mandatory to cover with materials containing asbestos all surfaces where the chimney goes to the roof.

Important points and tips

In order for a self-made brick oven to be safe and perfectly perform its functions, it is necessary to observe several basic rules:

In order for a self-made brick oven to be safe and perfectly perform its functions, it is necessary to observe several basic rules:

- alternation of masonry rows should be strictly observed;

- joints of bricks must be strictly horizontal and even;

- during laying, each subsequent row of bricks must be shifted 25% of the distance from the previous one;

- all doors and cleaning grates are mounted directly during the laying of the next row of bricks;

- metal elements are additionally strengthened with metal pins, the ends of which are embedded in the masonry of the furnace;

- every finished several rows of masonry is preferably dried for 1-2 days.

Subject to these recommendations, the exact adherence to technology and the use of quality materials, you can provide your home with warmth and comfort for many years.