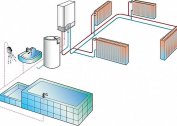

Today, manufacturers offer a wide selection of heating radiators: cast iron, steel, bimetal, aluminum. In many ways, the choice of this or that system will be determined by the type of heating system that works in your house, because water, having traveled many kilometers along the central heating system, significantly loses its quality: it becomes chemically aggressive and rather dirty.

Many radiators when using such a coolant quickly fail.

Cast Iron Radiators

Each of us is probably well acquainted with this type of heating devices. The undoubted advantage of cast-iron radiators is their highest reliability. They are well suited for use in domestic central heating networks, since these “batteries” are insensitive to either pressure drops or poor heat carrier quality. Cast iron radiators can also be successfully used in autonomous heating systems, if they use solid fuel boilers.

Each of us is probably well acquainted with this type of heating devices. The undoubted advantage of cast-iron radiators is their highest reliability. They are well suited for use in domestic central heating networks, since these “batteries” are insensitive to either pressure drops or poor heat carrier quality. Cast iron radiators can also be successfully used in autonomous heating systems, if they use solid fuel boilers.

Typically, manufacturers indicate the life of a cast-iron radiator in the range of 10-30 years, but under normal operating conditions, such a battery will last even 50 years. However, cast-iron batteries are not without their drawbacks, one of which is their very large weight. One section of such a heating device weighs about 6 kg, hence there are problems during transportation and installation of the heating radiator. Also among the shortcomings should be noted their high thermal inertia. Cast iron radiators heat up more slowly and cool more slowly.

Aluminum radiators

The material for the manufacture of these heating appliances is a special aluminum alloy with high thermal conductivity.

The material for the manufacture of these heating appliances is a special aluminum alloy with high thermal conductivity.

Aluminum radiators can very quickly warm up any room, however, the main problem that arises during the operation of these batteries is their insufficient mechanical strength. Such heaters may not withstand high pressure drops in the central heating system, so the use of aluminum radiators is recommended only in autonomous heating systems. In addition, the alkali used in washing heat networks dissolves the aluminum oxide film, as a result of which the metal reacts even with water, which once again speaks in favor of the fact that aluminum radiators and the domestic heating plant are completely incompatible.

It should also be borne in mind that aluminum is able to react even with copper, therefore, in autonomous heating systems, where the wiring is made of copper pipes, aluminum heating radiators are not allowed. Due to the fact that aluminum reacts with water to produce hydrogen, excess pressure will constantly build up in the system, which must be relieved to avoid damage to the radiator.

Steel radiators

This type of heating device is ideal for homes with autonomous heating system. Steel radiators are durable, although quite sensitive to the quality of the coolant, so you need to install them in urban apartments with a central heating system very carefully. These batteries also have good heat dissipation.

This type of heating device is ideal for homes with autonomous heating system. Steel radiators are durable, although quite sensitive to the quality of the coolant, so you need to install them in urban apartments with a central heating system very carefully. These batteries also have good heat dissipation.

Bimetal radiators

This type of heating device is a frame of their durable steel pipes coated with an aluminum shell. Steel tubes are designed to ensure the strength of the heating device, which allows you to operate it in a central heating system, withstand large drops and operate at a pressure of up to 40 atm.Aluminum shell improves heat dissipation. Thus, bimetallic radiators combined the advantages of steel and aluminum batteries. However, it should be borne in mind that the coefficient of thermal expansion of these metals is different, therefore, during operation, such heating devices can crack, emit unpleasant sounds and even deform.

Heat transfer methods for heating radiators

Also, one of the factors influencing the purchase of a heating device is which method it transfers heat to. The most efficient radiators are those that transfer heat to the surrounding air primarily by convection. So, the latter, due to the design features, heat the flow of air passing through the sections, and a peculiar air circulation is obtained: the warm stream rises upward, and the cold one comes into the section from below. This method of heating is much more effective than conventional heating by radiation, when heat is uniformly transferred by the entire surface of the device to the surrounding air. In addition to the fact that there are practically no air flows in this case, and the mixing of warm and cold air masses in the room is slow, a large proportion of the energy is spent simply on heating the walls behind the battery.

Also, one of the factors influencing the purchase of a heating device is which method it transfers heat to. The most efficient radiators are those that transfer heat to the surrounding air primarily by convection. So, the latter, due to the design features, heat the flow of air passing through the sections, and a peculiar air circulation is obtained: the warm stream rises upward, and the cold one comes into the section from below. This method of heating is much more effective than conventional heating by radiation, when heat is uniformly transferred by the entire surface of the device to the surrounding air. In addition to the fact that there are practically no air flows in this case, and the mixing of warm and cold air masses in the room is slow, a large proportion of the energy is spent simply on heating the walls behind the battery.

Cast iron batteries just have this drawback - these heaters transmit about 70% of the thermal energy by radiation, the rest - by convection. Consequently, insufficient efficiency is also added to the large weight of cast-iron radiators, which led to the mass rejection of these batteries, which we observe today.

In aluminum radiators, the ratio of convective heat transfer and radiation is approximately 60:50, in bimetallic ones - 50:50. Sometimes preference is given to “clean” convectors, the heat exchange of which is carried out only by convection, for example panel steel radiators.

Tips for choosing heating radiators

Regardless of the type of heating radiators, when purchasing them, it is necessary to focus, first of all, on the thermal power of the heating device. It is believed that for heating 10 square meters. m of space requires a heater of 1 kW. However, if the room has excellent thermal insulation and plastic double-glazed windows are installed, you can subtract 200 W from the total power, and if the heated room is angular, on the contrary, you need to add about 20% to the received power.

Of course, it is necessary to install heating radiators under the window, creating an obstacle to the cold air. In this case, it is necessary to focus not on the width of the opening, but on the design parameters, which we have already talked about. Otherwise, when the room overheats, oxygen begins to actively burn in it, worsening the well-being of residents, in addition, the high ambient temperature negatively affects the state of furniture and flooring.