Stove heating is the oldest way to maintain a comfortable temperature in the house. But even for this, at first glance, an inefficient heat supply method, there are a number of modern technologies for arrangement. These include heating a private house from the stove: water, wood, steam.

Furnace heating requirements

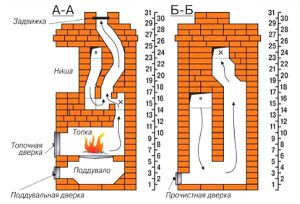

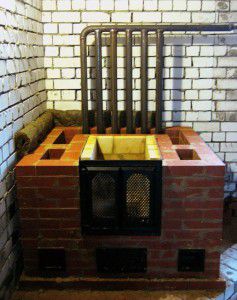

A traditional stove is a brick structure in which there is a firebox, an ash pan and a flue system. The latter played an important role, since the heating of the house was due to the heat of carbon monoxide, which passed through a complex system of channels.

However, for houses with a large area, such a scheme is not effective. Therefore, they prefer to do water heating from the stove with their own hands. To do this, a heat exchanger is installed in the furnace for heating the heat carrier - water, air or for generating steam. Such a scheme will increase the heating efficiency and significantly increase the heating area in the house.

But before you make air heating with a stove, you need to familiarize yourself with the rules of its organization. The main ones are ensuring the security of the system:

- It is recommended that the furnace not be mounted with a supporting wall so that a chimney duct system can be equipped;

- The material for the manufacture of floor and walls in the area of the furnace should be non-combustible;

- Mandatory installation of a protective door in the blower and firebox;

- Drawing up a schedule for cleaning the chimney from soot and soot. This procedure should be carried out at least 1 time in 2 months and before each heating season.

How to build a do-it-yourself stove with water heating? First you need to choose the optimal design that will meet the requirements of a particular house. There are many schemes of construction - from the simplest designs to complex ones with sunbeds and ovens.

The height of the chimney of the furnace should not be less than 4 m. Otherwise, due to the high temperature of carbon monoxide, condensate will accumulate on its surface, which will inevitably fall into the combustion chamber.

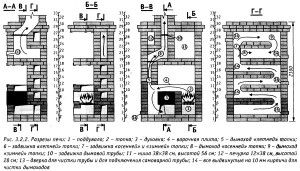

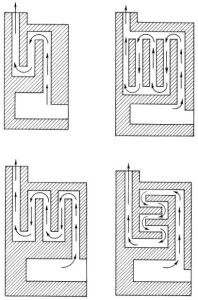

Schemes for the construction of a heating furnace

First of all, it is necessary to determine the functionality of the future furnace. Will it serve only for heating the coolant or have other possibilities. Most often, a brick stove with water heating is done together with the hob, which is very important for country houses.

It is also additionally recommended to make a complex chimney system. When hot carbon monoxide gases pass through them, the walls will heat up and heat will be transferred to the room. However, they can occupy up to 70% of the total furnace volume, which is not always possible for houses with a small area.

How to make heating from the stove "from scratch" on your own? First of all, you need to determine its location. The side walls of the structure will accumulate heat and transmit air to the room. Only then heating a private house from the stove will be truly effective.

The heat exchanger should be located in the combustion chamber at its rear. It must be made independently or ordered according to the drawings. Alas, the heating of a private house from the stove does not have factory heat exchangers. Their configuration depends entirely on the design of the furnace, its size.

After choosing a specific scheme, you can proceed with the construction of the furnace. The best option would be to purchase a finished steel model and cover it with a protective layer of refractory brick.But if you need really large and powerful stoves for a cottage with water heating - it is recommended to do it yourself.

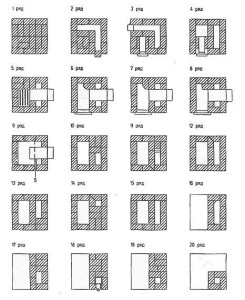

The construction of a stove for heating a house on wood begins with the construction of a foundation. It should not be tied to a common house. To do this, pour a concrete screed in the ground, and its height should be 5-7 cm above the floor level. Then you can proceed directly to the construction of the structure:

- According to the selected scheme, the first rows are laid up to the ash pan.

- A blower door is installed and bricked. Its standard size is 19.5 * 24 cm, made of cast iron.

- The combustion chamber is made according to the same principle.

- The chimney is best installed ready-made round section. So steam heating from the stove will be more efficient - the absence of vortex gas flows will not affect the draft.

It is best to use fireclay refractory bricks for furnace laying of the chamber and ash pan. The lining of the furnace can be done with ordinary silicate, since it has a good heat capacity.

Without experience, it is difficult to make water heating from the stove with your own hands. It is best to use the services of professional stove-makers at least in the early stages of construction.

Methods of furnace heating

Having understood how to make heating from the stove, you should correctly choose the method of heating the room. To do this, you can apply standard heat supply schemes, which instead of the boiler will have a brick structure.

The main selection criterion is the total area of the house. The required maximum cooling rate of the coolant depends on it as it passes through transport pipelines. Depending on this parameter, you can choose the following types of heating a private house from the stove:

- Water. The most popular and simple, but also time-consuming;

- Steam. Most often used for houses with a large area and high-temperature stoves;

- Aerial - the best option for a country house.

Each of the systems has a number of characteristic features of arrangement and operation.

Water heating stove

The most important component of water heating from a stove made independently is a heat exchanger. It is designed to transfer thermal energy from the combustion of fuel (wood, coal) to the water in the system. It is best to make it yourself, since each furnace often has individual dimensions of the combustion chamber. To do this, it is recommended to use heat-resistant steel with a thickness of at least 2 mm. The design of the stove for a cottage with water heating can be different. The main condition is to ensure maximum contact of the heat exchanger with the fuel combustion zone. For this, it can be made U-shaped so that it frames the combustion chamber.

Steel structure is manufactured using a welding machine. Before you build a stove with water heating in advance, you must draw up a drawing of the heat exchanger, subject to the following conditions:

- The internal dimensions must match the dimensions of the combustion chamber;

- The diameter of the nozzles for connecting to the direct and return line depends on the type of brick stove with water heating. If the system is closed, it is best to use steel pipes with a diameter of up to 30 mm. For open, the optimal option for highways is 40 mm. Thus, the loss of velocity of the coolant due to friction against the inner surface of the pipes is reduced;

- The heat exchanger is installed directly during the construction of the furnace. For installation in an old structure, it will be necessary to disassemble it before the furnace chamber is fully opened.

To improve the heating parameters, the installation of a circulation pump is recommended. It will contribute to an even distribution of thermal energy on radiators and batteries, and also significantly reduce the risk of coolant overheating.

For factory steel furnaces with a water heat exchanger, an arrangement of the foundation is not required.

Air heating stove

There is the simplest option of arranging air heating with a stove - to make a system of chimney channels with a large area for heating the room. However, this method has a drawback - volume limitations, i.e. it is impossible to heat a large house in this way.

An alternative option for air stove heating is the installation of a heat exchanger, as is done in fireplace heating. To do this, it is necessary to make a sealed structure similar to a stove with water heating. In it, hot air will heat up and, due to natural circulation, enter special transport channels.

However, in practice, such heating is very problematic. The chimney occupies most of the top of the stove, carbon monoxide from which in no case should be in contact with air in the heat exchanger. And for efficient air heat supply with a stove, a maximum chamber volume is needed. Also in the design process, you may encounter the following difficulties:

- The inability to upgrade an old stove for installing air heating;

- Supply channels for transporting hot air. Their diameter should be at least 100 mm, which causes difficulties in installation in the design of the furnace;

- Truly efficient air heating is only possible with a fan or similar devices.

It is because of these factors that air heating with a stove is not practiced. Not easier and faster to make steam. It is similar to a brick stove with a water heating circuit, but has a number of individual features.

For effective air heating, it is best to install a fireplace. It is more suitable for mounting a heat exchanger.

Steam oven heating

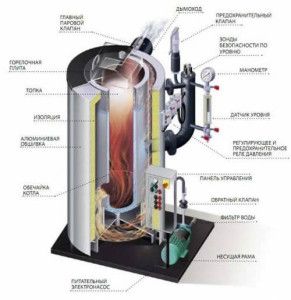

How to make steam heating from the stove at home? This will require special equipment, since the problem is not only in heating the water above + 100 ° C. It is necessary to organize its supply in the right amount for a certain period of time.

As an example, we can consider the principle of operation of a factory steam heating boiler. In it, the temperature of the combustion chamber is controlled by a group of devices. Therefore, gas models are most often used. In the volumetric heat exchanger, the formation of hot steam occurs, which is supplied to the pipelines using air pumps. Water is supplied automatically as the pressure in the heat exchanger decreases.

Is it possible to make a similar steam heating from the stove? In practice, it is practically impossible to implement. One of the problems is the inability to control the power of the combustion chamber. The following factors should also be considered:

- The problem with the location of the equipment. Monitoring devices and a water supply system should be located in close proximity to the heat exchanger;

- Steam heating from the stove cannot have mechanisms for regulating the flow of coolant into the pipes;

- Difficulties with the manufacture of a heat exchanger.

To make a full steam heating from the stove at home is almost impossible. Therefore, the best option remains water, as the simplest and most effective.

You can use steam heating units as the main source of thermal energy, and stove as an alternative.

If there is no way to make heating from a brick stove, you can purchase a ready-made factory design. On the market, several manufacturers offer similar options for arranging heating.

| Name | power, kWt | price, rub. |

| MBS THERMO VESTA | 16 | 49000 |

| Thermophore Professor Butakov | 16 | 28300 |

| Bavaria fireplace stove with tiles | 14 | 35000 |

You can also make a metal stove for a cottage with water heat supply yourself. But after installing it, it is still recommended to lay protective brickwork around the structure. This will increase heat dissipation and protect against hard IR radiation.

The video shows the stages of the construction of a furnace with water heating: