Among the options for heating a private house, a special place is occupied by waste oil boilers. They appeared relatively recently and caused a lot of debate about the practicality of their use. However, despite criticism, they are increasingly being used as the main source of heat. How to make effective home heating with used oil yourself: boilers, reviews and a description of the specifics of operation will help to solve this issue.

Principle of operation of waste oil boilers

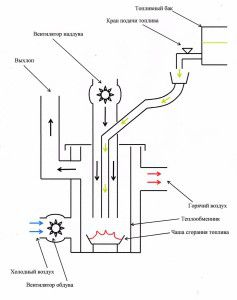

Fully-fledged air heating with used oil can be arranged only after familiarizing yourself with the specific design of the boilers. This type of fuel in its technical characteristics is similar to diesel, but has a greater amount of additives. They arise due to the specifics of the operation of the oil - in the car, industrial promise, etc.

Therefore, many factory heating oil boilers are in fact diesel. Their principle of generating thermal energy is similar to a car engine. With the help of the pump, fuel is injected into the nozzle with the simultaneous injection of a large amount of air. This mixture ignites, producing a large amount of thermal energy.

An alternative is the do-it-yourself oil heating boiler. In it, the fuel burns out as in ordinary solid fuel. However, the efficiency of the system is much lower. Therefore, experts recommend installing factory models.

This is due to their advantages:

- Accurate calculation of fuel consumption and air supply to the nozzle;

- Reliability and safety of work;

- Organization of a carbon monoxide exhaust system;

- Preheating fuel to increase combustion efficiency.

But at the same time, heating a house with used oil using factory boilers is characterized by high initial costs. You can slightly reduce them by purchasing a burner that is installed in a solid fuel boiler.

The nozzle diameter for the used oil must be larger than for diesel.

Expediency of installation

Is it really beneficial to heat a country house with waste oil? This option of heat supply can be applied only when accessing relatively cheap fuel. Otherwise, it will not be economically feasible to install complex and expensive equipment.

The heating of a country house with used oil, in addition to the boiler, must include a tank for storing fuel. It has special requirements. The use of open barrels is strictly prohibited, as used oil gradually evaporates. For this, closed containers are required. In addition to them, pumping equipment will be required to supply fuel to the combustion chamber.

Summarizing all of the above factors, we can distinguish the main requirements for the feasibility of heating with waste oil for a private house:

- Access to cheap fuel. For a house of 150 m² with 9 hours of heating, about 22.5 kg of oil will be required per day. For the heating season, this figure will be about 2200 kg;

- Special storage tank. Its capacity should be at least 2 months of consumption, i.e. about 500 kg;

- It must be remembered that the amount of soot at the waste oil heating stove will be an order of magnitude greaterthan diesel or solid fuels. In this regard, the frequency of cleaning the combustion chamber and chimney will increase.

Do-it-yourself heating with waste oil is done with the installation of a fan, not a turbine. This reduces the flow of air, which affects the composition of the combustible mixture. This technology leads to rapid clogging of the nozzle and its frequent failure.

You can negotiate with your nearest service center for the purchase of used oil. This is best done 4-5 months before the start of the heating season.

Security measures

The most important question for the consumer remains - is steam heating with waste oil safe? All complaints of foul smell and fuel ignition are associated with non-compliance with safety rules.

It is important to choose the right composition of the used oil. It should not contain waste gasoline, acetone and other flammable products. You should also pay attention to third-party impurities inherent in automotive mining. They are the cause of premature burner contamination.

For air heating on waste oil, the following safety measures should be provided:

- Chimney with a diameter of at least 100 mm. It is best to use a sandwich chimney, since less soot is formed on its surface;

- Storage of fuel tanks in the immediate vicinity of the boiler is not allowed;

- Waste oil tanks must be airtight. If water gets into them, fuel will spatter during burner operation. This may cause a fire;

- The temperature effect on the waste oil heating boiler is much higher than that of solid fuels. Therefore, the wall thickness of the heat exchanger and the combustion chamber cannot be less than 2 mm;

- In order to avoid smoke in the boiler room, a forced circulation system is arranged in it. Recommended air exchange should be 180 m³ / h per 1 m³ of area.

Only after meeting these requirements can we talk about a safe heating system for a country house with used oil.

The operation of a fan or turbine can take a large amount of air from the boiler room. Therefore, the capacity of the ventilation system of the room should be 1.2 times higher.

Overview of manufacturers of heating boilers for development

Reliable heating with used oil, reviews of which are mostly positive, is impossible without a factory burner. It will depend on it the safety and efficiency of the heat supply at home. Currently, foreign manufacturers of this type of equipment dominate the market. This is due to the complexity of production and the relatively low demand among Russian consumers for heating boilers for mining. Most models are designed for heating large rooms, and their power exceeds 60 kW. But despite this, it is possible to organize heating with waste oil in a private house and with the help of less efficient burners.

Boilers Clean Burn

The American company specializes in the production of powerful waste oil boilers. Its products are in demand in boiler rooms for heating 2-3 apartment buildings. The minimum boiler power is 200 kW. Feature is the unique shape of the heat exchanger, providing 95% efficiency.

Kroll Burners

The German manufacturer is profiling on the manufacture of waste oil burners. It is important that the company's engineers took into account the specifics of heating a house with used oil - the burner can be installed on almost any type of solid fuel boiler. In addition, it has a unique fuel heating system, so that its viscosity is close to ideal.

A feature is the mandatory presence of compressed air, which can be generated using a compressor. This is a prerequisite for the organization of heating on waste oil with your own hands.

Heat Boilers

This Russian manufacturer is one of the few who was able to make a truly unique heating equipment based on used oil. Their heating boiler "Zhar-20" with a rated power of 30 kW can be installed in a private house. It does not take up much space, and at the same time, all safety measures for steam heating with used oil are taken into account.

The price of equipment from the above manufacturers depends on the power of the boiler (burner), its design features.

| Model | price, rub. |

| Kroll KG / UB, 75 kW / h | 270000 |

| Clean Burn CB-2000, 200 kW | 580000 |

| Heat 20 | 170000 |

Before you purchase a specific boiler model, it is recommended that you read the reviews for heating with used oil. They will help to draw up an objective point of view on the performance of specific equipment.

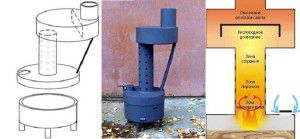

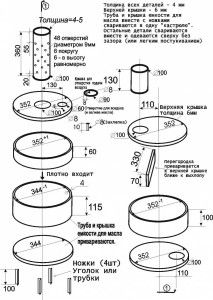

Homemade waste oil boiler

A waste oil heating furnace is not always necessary for heating a house. In some cases, it is made for heat supply of a garage, utility rooms. Then it is almost impossible to choose a factory model of a burner with a power of up to 10 kW. The only way out is to do it yourself.

The principle of operation of this device is based on the combustion of a mixture of oxygen and oil. During the combustion of this composition, the water tank is heated, located in the upper part of the structure. To make such a boiler for heating with waste oil, do-it-yourself will need to choose the right raw materials. The temperature in the combustion zone can reach + 700 ° C, so it is best to use heat-resistant steel grades.

To supply air, you need a compressor with a small capacity. The hose from it is installed in the pipe located next to the reservoir with waste oil. For ignition, a piezoelectric element or a similar device is installed.

Unlike factory burners, steam heat supply on waste oil has its own specifics of work. It lies in the principle of obtaining thermal energy. Consider the stages of heating on waste oil using a do-it-yourself boiler:

- The oil is heated to + 40 ° C as a result of which vapor forms in the upper chamber;

- In the combustion zone, air is mixed into the fuel swine, resulting in the release of a large amount of heat;

- The received energy can be directed to heating water in the upper heat exchanger or to enter directly into the room through the walls of the combustion chamber.

For this home-made waste oil boiler, it is important to correctly create a chimney system. It should freely remove combustion products from the premises. You should also consider the high oxygen consumption during fuel combustion. Therefore, for heating a country cottage on waste oil, an autonomous air supply system is made.

To adjust the power of the boiler, a valve is installed on the air supply hose. With it, you can reduce (increase) the flow of oxygen and the composition of the combustible mixture.

Used Oil Heating Reviews

How can you determine the relevance of installing a heating furnace on waste oil? There are many criteria - a calculated indicator of efficiency, operating comfort. However, the most effective way to find out about possible problems is to read reviews on heating with waste oil:

- We decided to make working out air heating in our service center. The benefit of fuel is always in abundance. They installed a home-made boiler and conducted a “field test”. The first problem is the mandatory cleaning of oil before filling.Even a small amount of antifreeze (which happens often) significantly increases the volume of soot. After finalizing the system, everything is functioning normally;

- We heard a lot about heating a private house with used oil - efficiently and at low cost. My husband works in electric networks and managed to agree on the sale of transformer oil at a good price. We installed a German burner on an old boiler, made a competent fuel supply. The system works like a clock. The only drawback is the high consumption - in winter up to 25 kg per day;

- For the garage, I made a homemade boiler at workout. It works fine - pre-installed a good chimney. The walls of the boiler are heated to red and therefore you have to blow them with a fan. He also noted that it is necessary to clean the furnace often.

From operating experience, it will take from 1 to 3 years to compensate for the initial costs of installing equipment in used oil. This applies only to boilers with a capacity of 60 kW and above.

The video shows an example of a homemade boiler: