Rockwool brand mineral wool boards of increased stiffness or ППЖ 200 are designed to insulate structures that are subjected to severe loads. They are made from durable mineral raw materials with the addition of binders. Before working with a heater, it is important to study its technical characteristics, pros and cons, and the available areas of its application in advance.

Description of insulation Rockwool ППЖ 200

Rockwool insulation ПЖЖ 200 is a mineral wool board made with basalt fibers. It is a non-combustible, hydrophobic and vapor-permeable material that has a dense fibrous structure. Plates of this type are impregnated with a binder synthetic component, ensuring their maximum strength. Due to the structure, they have a low level of thermal conductivity, which makes it possible to use them as a heat insulator. In this case, the temperature of the insulated surfaces can reach 200 degrees.

Plates from the manufacturer Rockwool are made from phenol-free environmentally friendly raw materials. They have a Hygienic certificate, which makes it possible to use them in the field of civil engineering, as well as a radiation safety certificate. The thickness of the plates can vary between 50-100 mm with a step gap of 10 mm. All materials of this type are produced with the addition of water-repellent additives to prevent the development of fungi and mold.

Specifications

Plates ППЖ 200 belong to the low-combustible group of materials of category G1 and highly inflammable category B1 according to GOST 30244. This factor is their main advantage. ППЖ insulation contains inhibitors to increase corrosion resistance during contact with metal. Due to their optimal characteristics, they can be used for thermal insulation of reinforced concrete floors, as well as standard-type wall panels.

The compressive strength of the plates during 10% deformation varies between 0.1-0.8 MPa, moisture absorption is 8.8% by mass and 2.7% by volume. The ultimate tensile strength of the material is 0.01 MPa, the separation of layers 0.042 MPa, the vapor permeability is 0.049 Pa. Thanks to the convenient and stable shape and volume of the miniplite, ППЖ 200 is easily cut and processed. The plates are packed in 2-4 pieces with a protective shrink film, the volume of one pack is 0.08-0.12, taking into account the thickness.

Advantages and disadvantages

Heater Rockwool ППЖ 200 has its advantages and disadvantages, which must be considered before purchasing. Of the advantages of mineral wool plates of this type note:

- high level of mechanical tensile, compression and tensile strength;

- increased heat resistance, melting of mineral plates is possible only after 2 hours of exposure to a temperature of 1000 degrees;

- resistance to chemical components, damage to insects and rodents, the formation of mold;

- vapor permeability;

- durability, ability to maintain volume, shape, thickness and weight;

- the absence of problems during installation and during processing, which allows you to cut plates without much effort and use them for thermal insulation of complex structures.

The Rockwool minplit used for thermal insulation has practically no drawbacks, with the exception of the high cost and the specific smell of urea, which is added during the production process.

Areas of use

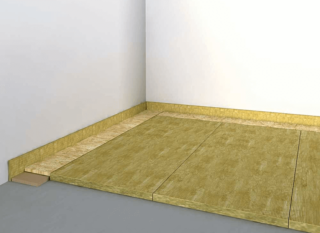

Minplita Rockwool ПЖЖ 200 can be used for various construction needs. Brand boards are used for insulation of load-bearing structures and floors, as well as roofs, wall panels, floors between floors and structures made of corrugated board or reinforced concrete. ППЖ 200 are suitable for insulating stucco facades, but they need to be reinforced with steel mesh. With their help, they increase sound insulation by laying slabs of mineral wool under a cement screed in the floors.

Plates of this type are suitable for thermal insulation systems of industrial equipment, as well as for industrial premises. They have a wide range of applications, with sheets of ПЖЖ 200 it is possible to isolate the roofs of roofs and attics for the purpose of fire protection. Sheets help to further increase the fire resistance of materials and metal structures. In roof structures, slabs are responsible for the thermal insulation properties and strength of the entire roof as a whole. When used for insulation of floors and floors, sheets provide thermal and sound insulation.

Mineral wool board production process

Rockwool PPZh-200 plates are made from natural basalt raw materials, due to which mineral wool has good sound and heat-insulating properties. This effect is achieved by processing the starting materials using high temperatures. In the process, special fibers are formed inside the raw material, which bind to each other with the help of an adhesive substance and form separate plates. The resulting material fully retains its pristine qualities and has a long service life.

Miniplates belong to the category of environmentally friendly materials, since basalt rocks and gabbro are used for their manufacture without the addition of metallurgical wastes. During the production of plates are subjected to melting with the drawing of fibers, this process is similar to the formation of the material in natural conditions. ПЖЖ-200 from Rockwool are created by laying the fibers in a chaotic manner, which favorably affects the technical characteristics of the material and reduces its weight.

The unique structure of the plates allows them to maintain the necessary level of rigidity and not lose their resistance to tearing. The material is impregnated with water-repellent oils to increase hydrophobicity, which allows the use of plates even in high humidity conditions.

Rules for choosing Rockwool insulation ППЖ 200

When buying PPZh-200 boards, their technical features and characteristics must be taken into account, and they must be checked for compliance with the requirements. Rockwool materials from the manufacturer have a rectangular shape, the optimal level of density and stiffness. Small particles of fiber should not be strewed from them, high-quality plates do not miss during installation and are able to maintain the initial volume. During the selection of plates, the dimensions of the insulation itself and the features of the installation object must be taken into account. Despite the incombustibility of the PPZh-200, it must not be allowed that the plates are too close to the electrical wiring.

The combination of plates with foil mineral wool provides optimal thermal insulation. This mineral wool is a basalt insulation glued with aluminum foil. Experts recommend paying attention to the density of products, the degree of resistance to loads and the ability of plates to maintain their original shape even with strong compression depends on this indicator. For floors, ceilings and partitions, it is recommended to use heaters with a density of up to 50-100 kg / m3, for facades up to 100-125 kg / m3, for horizontal surfaces up to 35 kg / m3, for screed up to 200 kg / m3. Materials with the correct density indicators provide maximum comfort and convenience at all stages of operation of the insulation.

The manufacturer recommends monitoring the storage conditions of ППЖ-299 plates, on which their quality largely depends. Storage of insulation is allowed on pallets made of wood in a package of durable polyethylene, which should be without damage. Also in the room you need to create optimal temperature conditions.