For the arrangement of heating, elements made of modern materials - polymers, aluminum, are increasingly being used. And, it seems that over time they will finally replace all other components. But in many cases, without the latter it is impossible to make high-quality and effective heating of a house or apartment. What functions do metal heating elements perform: batteries, pipes, radiators, screens? First you need to consider their unique properties.

General characteristics of metal elements

Steel alloys were used in the very first heating systems. This is due to their increased heat resistance, good heat dissipation and relative cheapness. Subject to operating rules, metal radiators can last up to 40-50 years. The same applies to radiators.

Their main advantage is mechanical strength. Depending on the steel grade, the temporary resistance can reach 300 MPa. Modern metal panel radiators are effective due to the high rate of thermal conductivity. Its average value is 70 W / m * K. Together with the possibility of hot and cold processing of workpieces (stamping, welding, casting), these characteristics make it possible to produce reliable components of a heating system of various shapes and designs.

Consider the main consumer properties of metal elements:

- The ability to withstand high pressure without deformation - up to 50 atm;

- Corrugated metal pipes for heating are used to set the turning angles of the highway, connecting them with rigid ones. This allows you to reduce the number of joints in the pipeline;

- Painting. After a slight surface treatment, a special paint (heat-resistant) can be applied to the metal. Thus, the heating will look harmoniously in the overall interior of the room.

The disadvantages include the complexity of the installation. The main pipes for heating are metal, with a diameter of 20 mm and above, it is recommended to connect by welding. Smaller cross-sections are joined by thread.

When choosing the metal components of the heating system, it is necessary to carefully study their operational and technical properties.

If there is a high probability of occurrence of water hammer or sharp pressure drops in central heating - it is best to install metal pipes.

Metal pipes for heating

For the manufacture of heating pipes, the so-called "black" metal is used. In it, iron is the main part. This directly affects the complexity of manufacturing and, as a consequence, the cost.

Most often, the installation of heating from metal pipes is performed from products with a diameter of 15 to 40 mm. In closed systems with forced circulation, pipelines with a cross section of 15 to 25 mm are used. In the open, the main line is equipped with pipes up to 40 mm. This is necessary to reduce hydraulic resistance.

The choice of pipe sizes for metal heating depends on the preliminary calculations of the system. But in addition to this, one should take into account such features:

- If flat metal radiators are installed in the system, the diameter of the connection pipes must coincide with the cross-section of the pipeline;

- The roughness of the inner surface of the pipe. This creates additional resistance when moving the coolant. To reduce this indicator, the installation of large diameter pipes is recommended.But at the same time, the total coolant volume in the system will increase;

- The metal has high thermal resistance - up to 500 ° C;

- When installing heating from metal pipes in the presence of an electric boiler, the grounding of the entire circuit is necessarily done.

Until recently, only solid or welded pipes with high rigidity were used in the arrangement of heating. But besides them, they began to use flexible models.

If polymer pipes are installed, they make the cutting sections of the metal from the boiler without fail. Their length should be at least 2 mp everyone.

Corrugated pipes for heating

A metal corrugated pipe for heating has appeared on the market relatively recently. Before that there were models designed for cold water supply, the characteristics of which were not suitable for heating.

It is made of stainless steel. First, with the help of molding machines, a cylindrical workpiece is made. Then welding takes place in a special environment - this is the most complex process, since it should not lead to burning of alloying metals. To improve the strength characteristics, corrugated metal heating pipes are exposed to high temperatures and then cooled. This process is called annealing.

The result is an elastic construction, the maximum bending radius of which can reach 3-4 diameters.

The result is a metal corrugated pipe, which in the heating system will have the following features:

- Simple threaded installation. You can use models with threaded fittings already installed, or install them yourself, cutting the pipe of the right size in advance;

- The properties of stainless steel prevent the appearance of limescale on the inner surface of the pipe;

- Possibility of installation in the highway from copper pipes, as well as with bimetallic radiators. Stainless steel does not form galvanic pairs with these materials, i.e. there will be no corrosion at the joints.

The main disadvantage of a corrugated metal pipe for heating is its high cost.

| Name | price, rub. |

| Corrugation, d-15 mm, m.p. | 175 |

| Corrugation, d-20 mm, m.p. | 305 |

| Corrugation, d-25 mm, m.p. | 343 |

| Corrugation, d-32 mm, m.p. | 735 |

| Coupling, external thread, ½ ” | 107 |

| Coupling, external thread, ¾ ” | 173 |

Most often, corrugated metal pipes for a heating system are installed to connect radiators or as elements of a warm floor.

For heating with high temperature conditions (90/70 or 95/80) you need to use an annealed corrugated pipe.

Installation of metal heating pipes

When drawing up the installation diagram for metal pipes, one property must be taken into account - they have a high specific gravity, depending on the diameter and wall thickness. For solid-rolled or welded models, it is recommended to adhere to the following installation rules described in GOST 3262-75:

- Galvanized models can only be adopted with threaded connections. For this, it is best to use factory-made couplings and adapters;

- Thin-walled highways of "black" metal are connected by gas welding. The use of electric arc is impractical, since there is a high probability of burning;

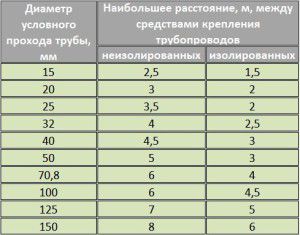

- The distance between the fasteners should correspond to the table;

- For bending pipes of small diameter (up to 20 mm), you can use a special machine.

For corrugated lines, installation is even easier. Before connecting to a flat metal radiator, measure the required length. It is important to consider the dimensions of the fittings. Then, with the help of cutting equipment (scissors), the pipe is cut, and fittings are installed at its ends.

After installing the heating from corrugated metal pipes, make sure that they are not twisted.This creates excessive surface tension, which can cause premature failure.

Metal heating radiators

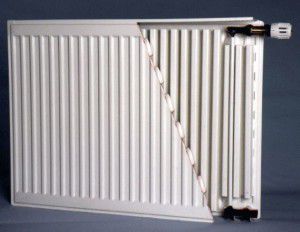

Along with bimetallic or aluminum radiators, metallic radiators for heating have good performance characteristics. They differ from standard designs in monolithic (non-separable), affordable cost and long service life.

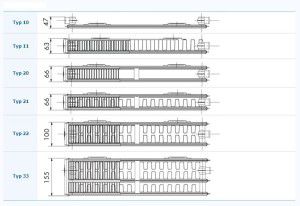

A design feature is the heating of the room using the convection method. For this, metal panel radiators for heating should consist of 2 components - a body and a piping system through which the coolant flows. The transfer of thermal energy occurs due to the snug fit of the pipes to the metal ribbed surface. For better convection of air flows, special channels are provided inside.

When choosing metal batteries in a heating system, you need to pay attention to the following characteristics:

- The number of heating panels - from 1 to 3;

- Total battery area. Heat transfer and rated power depend on this;

- The thickness of the metal should not be less than 1.25 mm;

- The panels must be interconnected by roller welding. Visually, the thickness of the seams does not exceed 2-3 mm, in contrast to the point or arc;

- If there is insufficient heating area, but an acceptable radiator power, you can additionally install metal screens on heating radiators

The advantage of metal panel radiators in the heating system is a high threshold for maximum pressure. It can reach 50 atm.

For the full operation of flat metal radiators in heating, the installation of temperature regulators and Mayevsky taps is recommended.

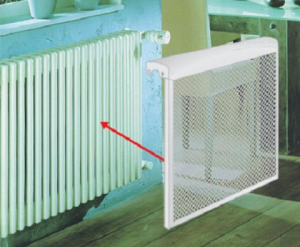

Metal screens on radiators

The appearance of radiators is not always acceptable for a particular room interior. This can be fixed by installing screens for heating radiators made of metal. But besides this, they perform other functions.

If the heating system provides a high-temperature mode of operation, it is likely that burns will occur when the battery is touched. The metal screen in this case performs protective functions, since it touches only a small part of the radiator. As a result, its heating level is much lower.

When choosing the optimal model, it is recommended to pay attention to the following characteristics of metal screens on heating radiators:

- Installation method. Most often, the design provides for the internal ribs on which the screen rests;

- Closing area. It can only be the front of the radiator. If necessary, you can choose a model with side screens;

- The size must exceed the dimensions of the radiator by 10-15 mm;

- The ventilation part must be present on the front part. Do not install homemade continuous screens for heating radiators metal. This will lead to a significant deterioration in air convection.

In some cases, it is necessary to close the outer pipes for heating from metal. You can also use screens for this. It is important to choose the right size.

Regardless of whether metal screens for radiators or steel pipes are used in heating, they should be protected from corrosive processes. The best way is to apply the paint and varnish outer layer, use distilled water as a coolant (prevents the appearance of scale) and timely flushing of the system. Such an integrated approach will significantly increase the time of non-repair service of elements.

In the video material, you can find practical recommendations for installing steel pipes in heating: