Rockwool insulation will help protect your home from the cold and draft. Brand products are known worldwide. One of the largest manufacturers of heat and sound insulation offers stone wool insulation. Non-combustible and safe material helps maintain an optimal microclimate and a comfortable room temperature.

Features of technology and production of insulation Rockwool Scandic

The first thermal insulation materials under the ROCKWOOL trademark appeared in 1937. Rocks became the raw material for the production of insulation. Over the years of development, the company has significantly improved its thermal insulation manufacturing technology, but the original product has remained the same. Basalt stone provides durability, environmental safety and incombustibility of mineral wool. The molten feed is placed in a centrifuge where thin, strong fibers are formed. They are arranged in a chaotic order, but reliably intertwined with each other. The material is treated with water repellent compounds to reduce moisture absorption.

Especially for warming low-rise buildings, the company has developed a series of Rockwool Scandic products with characteristics that make installation work faster and easier. The material is created using Flexi technology. One edge of the insulation is able to shrink during installation, and then restore shape. The width of the elastic section is 5 cm. For installers, it is marked. Advantages of the new technology:

- It simplifies the installation of the plate in the assembled frame of wooden beams or metal guides. It is not necessary to cut the mineral plate, it is enough to compress the elastic edges and to fill between the guides.

- The insulation does not require additional mounting during installation on an inclined and vertical surface. Work can be done by one person.

- Tight fit eliminates the appearance of cracks and bridges of cold.

Another feature of the Scandic series is its high compression ability. The material can be compressed by 60-70%, and after removing the load, it returns to its original shape. This feature allows compact packaging of plates for transportation. The insulation is completely in a dense plastic film. The procedure takes place under vacuum. Compact packaging can be transported by car.

Advantages and disadvantages

The heat insulator has the following advantages:

- Low coefficient of thermal conductivity - the fibrous structure of mineral wool with many air layers actively prevents the movement of heat and cold. Warming with basalt plates ensures a stable and comfortable temperature in the house with minimal heating costs.

- Vapor permeability - in each room there is wet steam. To maintain a healthy microclimate, it needs to go out. The porous structure of the mineral insulation provides high vapor permeability of the material.

- Sound insulation - randomly located stone fibers and voids between them contribute to the attenuation of the sound wave. Rockwool boards are used to create soundproof partitions between rooms or floors and acoustic ceilings.

- Flammability is one of the criteria for a good insulation fire safety. Stone cotton slabs are resistant to fire, withstand temperatures above 250 ° C. They do not support combustion, do not emit smoke when heated.The material belongs to the fire safety class KM0.

- The environmental safety of the insulation is confirmed by the EcoMaterial Green certificate. The raw material for its manufacture is natural stone. The product is safe for human health, it is recommended for installation in residential premises. In order to reduce environmental pollution, the company processes waste basalt wool for the production of new heaters.

- Durability - a strong interweaving of basalt fibers ensures the uniform shape of the plates throughout the entire period of operation. Hard mineral wool does not crumple, does not deform. With proper installation, its heat-insulating properties are preserved for more than 50 years.

- Convenience of installation and transportation - Rockwool slabs have a standard size. During installation, the frame is assembled with a step equal to the width of the material. Mineral wool is easily placed in it, and thanks to Flexi technology, the laying process is accelerated. The compression of the plates in the package allows you to load more material during transportation.

- Resistance to biological and chemical effects - stone fibers are not affected by fungus and mold. They are not selected by rodents for housing. Basalt slabs are resistant to most chemical compositions, but at the same time do not cause corrosion when in contact with metal.

Disadvantages:

- Mineral wool is composed of organic binders. The composition is harmless at operating temperature. Rockwool uses a small amount of binder.

- Basalt fibers during installation can cause an allergic reaction. It is recommended to lay and cut the plates with gloves, a respirator and goggles.

Thanks to special processing, basalt wool is characterized by a low percentage of water absorption. But direct contact of the insulation with water must be avoided. Installation of thermal insulation should take place in dry weather. After installation, the plates are closed with a waterproofing membrane.

Dimensions of the Scandic series insulation

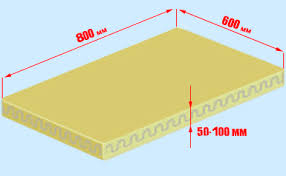

Scandic series products are available in two sizes, with several options for the thickness of the plates:

- The standard option is a plate 800 × 600 mm, thickness - 50 and 100 mm. The number of sheets in a pack of 12 and 6 pieces.

- XL size insulation - plate 1200 × 600 mm, thickness 100-150 mm. The number of products in a pack of 6 and 5 pieces.

The manufacturer indicates that the bundle contains from 3.6 to 5.76 m2 of mineral wool. Information allows you to calculate the required amount of material. It is worth considering recommendations for the effective thickness of thermal insulation. For walls, it is 100-150 mm, for the roof - 200-250 mm. In the manufacture of products, the linear dimensions of the plates are clearly observed. Thermal insulation does not change shape during the entire period of operation.

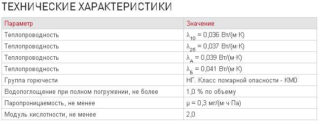

Specifications

The operating parameters of the material are related to the characteristics of raw materials and production technology. Inorganic raw stone provides strength and durability of the fibrous material. Mineral wool has specific properties that determine its advantages and disadvantages. In the catalog of the manufacturer ROCKWOOL Light Butts Scandic, the technical specifications are as follows:

The operating parameters of the material are related to the characteristics of raw materials and production technology. Inorganic raw stone provides strength and durability of the fibrous material. Mineral wool has specific properties that determine its advantages and disadvantages. In the catalog of the manufacturer ROCKWOOL Light Butts Scandic, the technical specifications are as follows:

- The coefficient of thermal conductivity is 0.036-0.039 W / m * K.

- Vapor permeability - 0.3 Mg / (M * h * PA).

- The compressibility factor is not more than 30%.

- Water absorption - 1 kg / m2.

- Combustibility group - NG.

Mineral wool is an excellent sound insulator. With proper installation, it reduces noise by 42-63 dB. Technical characteristics of the insulation Rockwool Light Butts Scandic ensure the durability of its operation. Plates do not lose their properties for about 50 years.

Density

For Rockwool Light Butts Skandik boards, the density is 37 kg / m3. This is an indicator of universal insulation, which can be used in various areas that are not exposed to high loads.Medium stiff fiber boards are the best option for soundproofing rooms. They are characterized by low thermal conductivity and minimal weight. The insulation does not load the supporting structure. Material of low density is cheaper than more rigid analogues.

Scope of use

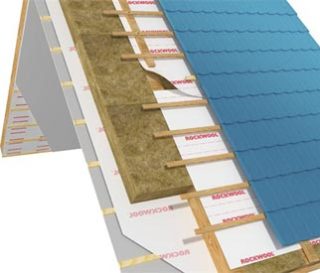

Thermal insulation Rokvul Scandik low density designed for private construction. It is used in the construction of houses, garages, farm buildings, baths and saunas. Elastic plates can be installed in various sections of the structure:

- frame walls;

- external insulation for siding;

- attic and floor floors;

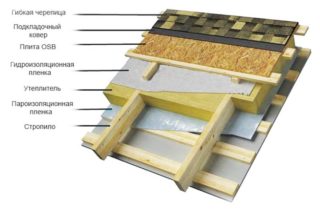

- pitched roof.

The scope includes only non-loaded structures. This feature is associated with a low density of material. The low rate of water absorption and resistance to fire allow the use of stoves when warming baths. The material is laid in the frame of the partitions, closed with a foil vapor barrier. Increased humidity in the bath negatively affects the condition of the insulation. The use of non-combustible basalt wool increases fire safety. When installing mineral wool, personal protective equipment must be used.

Insulation of buildings with slabs Rockwool Scandic reduces heating costs, speeds up work processes. The materials are easy to install, reliable and durable.