Organization of heating in a private house is one of the most important types of construction work. The installation of a gas floor boiler to provide heating for the building is very popular among consumers.

General characteristics of a gas floor boiler

Gas boilers are available in several versions. They can be floor and wall. Wall-mounted are characterized by compact size and good performance. But most often in private homes they prefer the installation of floor equipment. This is due to its positive properties:

- Great power. The designs of these appliances can deliver more power than wall-mounted models.

- You can find non-volatile models that will work with a coolant moving without using a pump.

- Long life equipment. With well-chosen parameters and proper installation, the boiler can work for more than 50 years.

- Profitability and simplicity in leaving. Floor-standing boilers, unlike wall-mounted boilers, are made without built-in automation. They also do not have additional equipment. This reduces functions, but significantly simplifies maintenance and repair, increases the life of the device.

The installation of gas boilers has its drawbacks. The device must be located in a separate room for safety reasons. The room has a number of requirements that must be strictly observed. If the boiler room does not correspond to them, it will not be possible to obtain permission to launch gas equipment.

Types of floor gas boilers

The gas floor boiler can be single-circuit or double-circuit.

Single-circuit

With a single-circuit device, the boiler will only heat the coolant, function as a heating device.

The equipment is equipped with one heat exchanger. Due to this, its design is simplified, dimensions are reduced. However, if water heating is required, additional equipment will be required. Most often in such a situation they put an indirect heating boiler. Single-circuit floor heating gas boilers are selected for buildings in which hot water supply is not required. They are also used for large areas where all the power is spent on heating the building.

Double-circuit

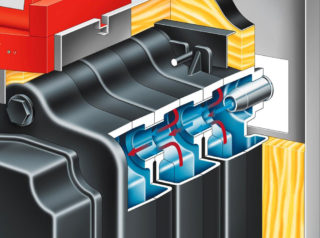

Floor gas double-circuit boiler is a more complex design. It is intended for heating the coolant and for providing the house with hot water. In dual-circuit devices, two heat exchangers are built-in.

Manufacturers produce models with bithermic heat exchangers, which are divided into segments. One of them moves the coolant in a different way the heating water. Such devices will be the most compact, but they are less reliable in operation.

It is optimal to purchase a unit with two completely separate heat exchangers. They form less scale. The circuits will be divided, so there is no need to block the heating at the time of distribution of hot water.

Double-circuit boilers are best suited for small buildings. If such an apparatus is used for large areas, separation of contours will be required. This is necessary for safety requirements.

Advantages and disadvantages

Depending on the design features, the floor boiler has its positive and negative sides.

With integrated boiler

Single-circuit boilers with a boiler have several advantages:

- Large internal cross-section of the heat exchanger. Due to this, scale formation is reduced.

- Simplicity of design provides a high rate of reliability.

- The consumption of thermal energy will be the most rational.

- The water inside the boiler always has the same temperature, since it is not affected by pressure surges in the gas line.

- The kit “boiler and gas boiler” will fully provide hot water and heat to the entire building.

The downside is that the correct operation of the boiler depends on the quality of the water, which most often does not correspond to the norm.

With cast iron heat exchanger

Boilers with a cast-iron heat exchanger have the following advantages:

- Durable, resistant to corrosion.

- Uniform distribution of heat due to the material is ensured.

- Cast iron has excellent technical properties.

- The material is resistant to environmental influences.

- A cast-iron heat exchanger can withstand high temperatures.

- The material has a long service life.

The disadvantages of cast-iron heat exchangers include:

- heavy weight, which makes transportation difficult;

- cast iron is afraid of temperature changes - if water gets on the hot material, it may burst;

- It is very difficult to carry the boiler with a cast-iron heat exchanger, as the material is fragile and can crack if it is accidentally dropped.

Cast iron heat exchangers are installed only on floor-standing boilers.

Non-volatile

The main advantage of non-volatile boilers is that there is no need to connect electricity. Due to the minimum number of nodes, the device is very compact, easy to install. Double-circuit floor-mounted non-volatile boilers are able to provide the house with hot water and full heating in an area with unstable power supply.

Devices of this type will work well only if there is sufficient pressure in the gas line. This point is a minus.

Selection requirements

When choosing a gas boiler for the house, it is necessary to take into account a number of nuances that are associated with the technical characteristics of the building, as well as the installed heating system. The following parameters should be noted:

- Power. Determines the maximum area that the device can heat. If it is not enough, the life of the boiler will be reduced due to premature wear of parts. If a double-circuit gas boiler is purchased, 25% is added to the capacity necessary for heating all rooms.

- Fuel consumption. Preferences in this situation should be given to units that have electric ignition, which reduces fuel consumption.

- Heat exchanger material. Devices in which a cast iron element is installed have a longer service life.

- Availability of power consumption regulation.

- Performance. It is relevant for double-circuit floor gas boilers and depends on the number of people living in the house.

- The maximum temperature for heating hot water. Most often varies from 80 to 90 degrees.

The dimensions of the gas boiler are selected taking into account the place of its installation. When choosing equipment, it is also recommended to pay attention to additional functions and features. They are aimed at improving security.

- Protection against overheating and freezing. This is the most relevant function for purchasing a heater in country houses, in which no one lives in the winter.

- Gas control system.It involves the installation of sensors that will turn off the equipment in the absence of gas supply.

If you plan to organize hot water supply, it is worth choosing models with two circuits.

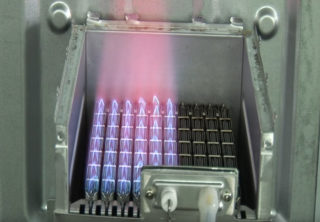

Types of burners

Burners of floor boilers are divided into one, two-stage and modulation. Single-stage systems assume that the device can produce only one power level; in a two-stage system, it is selected from two levels. Modulation controls the available power. The efficiency of the equipment depends on the type of burner.

Inflatable burners are equipped with turbines for heating. They take air from the room and from the street. They do not require a separate room.

Atmospheric burners are one of the most reliable at an affordable price. Their minus is air burning and low efficiency.

Automation Dependence

In gas equipment for heating, automation plays the role of additional safety. Thanks to special functions, the operation of the devices becomes more reliable, a constant optimal temperature is maintained.

Automation performs the following tasks:

- shuts down the system when the gas supply stops;

- adjusts the power level of the burner;

- displays indicators on the display.

Additional features prevent damage to the device.

Manufacturers Rating

In the market of equipment for organizing heating, a wide selection of floor gas boilers is presented. When buying, it is important to pay attention to manufacturers who are in consumer demand. Many companies use modern innovative developments that allow them to produce devices with excellent performance characteristics. The most popular manufacturers are:

- Lemax Domestic manufacturer, which offers a wide range of floor boilers, powered by gas. The main models are Patriot and Leader. Lemax produces both single and dual circuit devices.

- Don. Russian manufacturer of powerful devices designed for heating areas from 300 square meters. Thanks to the use of high quality materials and built-in automation, boilers of this manufacturer are widely popular.

- Buderus. German manufacturer offering premium condensation and convection type devices. Boilers are presented in a wide range of power.

The purchase of gas equipment to provide space heating and hot water supply is an excellent option for private country houses.