Autonomous heating systems with a Neva Lux boiler do an excellent job of heating residential and non-residential premises. They are better adapted to the harsh climatic conditions of Russia, more economical than central heating systems. Thanks to the simple device, the vast majority of faults are repaired independently by the customer or the installation organization. Some important components are supplied from European manufacturers.

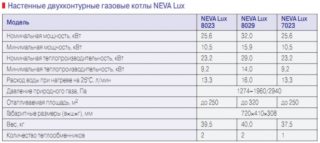

Specifications

Various modifications of gas boilers Neva Lux are suitable for heating homes, industrial and office buildings. Their modifications heat rooms with different sizes. High reliability and "smart" automation brought these boilers to the leading position among Russian manufacturers.

Specifications:

- Thanks to the powerful gas supply pump, they can work in low pressure systems. The pump itself will create the necessary conditions, depending on the settings set.

- Copper heat exchangers have higher efficiency than cast iron and steel models.

- All the most important mechanisms are made in Italy. Localization of production is limited to the manufacture of the housing and low-value parts. Cooperation with foreign partners, the use of European technologies favorably affects the quality and cost-effectiveness of the product.

- Foreign technology provides a 100% level of security.

- Easily adapt to specific operating conditions.

- The coefficient of performance reaches 98%.

Thanks to the interaction of European manufacturers, the consumer is provided with a technological and reliable device of high quality.

The main types of boilers Neva Lux

In the lineup there are 2 basic modifications - Turbo and Suite. Turbo boilers are volatile. For their uninterrupted operation, uninterruptible power supplies, a 220 V network, an electric generator are required.

Neva Lux boiler is regulated by a thermostat. Automation works completely autonomously and reduces fuel consumption. As a result of automatic regulation, the control unit independently adjusts the temperature regime depending on the degree of heating of the room.

Double circuit gas boiler

Traditionally, the company produces models for trunk gas. But for those who only have liquefied in stock, several models are available.

Double-circuit gas boilers are designed for heating and hot water. Owners of apartment buildings can refuse utilities and provide themselves with hot water themselves. It will come out cheaper. The water temperature can be adjusted.

Single circuit gas boiler

Models with one thermal circuit are smaller than double-circuit ones in size. Their operation is much simpler. They only maintain the temperature of the coolant in the heating system. Of the current off-season maintenance, the most important is the cleaning of the working chamber and the chimney from soot. Annual prophylaxis will prevent significant operational problems.

Installation and Connection

Neva Lux boilers are installed as follows:

- The equipment is hung on the wall with special strips.

- Ball valves are installed at the inlet and outlet of the boiler to facilitate operation and repair.

- Filters are placed using sweeps.

- The hot water and heating system is brought up, or the boiler is included in the existing water supply.

The boiler must be connected and set up by certified employees of the gas company.Neva Lux is usually located in the kitchen or in the utility room with a ventilation system. When choosing the installation site, you should take into account the places of water and gas pipes.

Typical malfunctions

Any complex equipment during long-term operation fails. The main indicator of reliability is a quick commissioning through repair with the elimination of typical faults. For any heating equipment and installation work, a warranty card is issued. Therefore, calling the wizard during the warranty period will be free - the manufacturer’s warranty will cover equipment malfunctions, and the installer will eliminate installation flaws.

A list of major equipment errors can be found on a special display.

Error 01

In the Neva Lux boiler, this type of error means the impossibility of igniting the device.

- Check valve opening and gas supply. Call the gas service if necessary.

- The clearance between the candle and the burner should be 5 mm. Adjust.

- Isolate the breakdown place when a candle is broken.

- Clean the contaminated candle.

- Ring the ignition transformer circuit.

Error 03

Accumulation of condensate in pipes causes error type 03.

- The chimney is clogged or its design is broken.

- Depressurization of the pressostat tube or a violation of its power supply.

- Fan failure.

Error 04

Error 4 indicates insufficient pressure in the heating circuit. This interferes with the functioning of the units and contributes to overheating of the boiler.

- Raise the pressure in the circuit.

- Remove the air plug with an air vent valve.

- Check pressure sensor.

- Clean the pump and inspect the connections.

A complete list of errors is given in the instruction manual. Some troubles in the form of replacement parts are carried out by the master on the spot. The reasons for the failure are due to improper maintenance or insufficient conditions for the operation of the nodes. After repairing the units, the unit works like new.

User manual

The instruction is included with the equipment. It can also be downloaded from the official page of the manufacturer - NEVA (Russia) in PDF format.

The document stipulates: technical characteristics of devices, safety parameters, requirements for installation and installation of the boiler. Also given are diagrams of the device and the control panel, recommendations for igniting the boiler and methods for connecting it. The methods of seasonal inspections, maintenance, care of the unit are described. The table lists error lists and methods for resolving them. At the end there are marks on the acceptance of the device, warranty, a list of service centers is given.

When working with equipment, the instruction should be at hand. If you cannot fix the error yourself, you should call the service center and call the wizard.

Boiler line overview

An update to the Lux model line is the new Turbo. This is a separate series of equipment. It is made taking into account the advantages and disadvantages of the previous modification.

Widely used models:

- For heating an apartment, a home, a single-circuit boiler in a wall version is suitable. Instead of a water circuit, an indirect heating boiler can be installed. Modulation burner allows you to effectively save fuel. The boiler 8618 attracts with its simple design and low cost. It lacks volatile complex electronics. Compact dimensions allow installation in small rooms. The circulation pump in the boiler makes it possible to connect to existing heating systems. It is allowed to connect an indirect heating boiler, forced smoke exhaust fan, room thermostat.

- Very popular among dual-circuit models are the 7218 and 8224 Lux series.Modern automation monitors the temperature in the hot water supply and at the same time feeds the bends of the warm floors. To reduce heating costs, a separate thermostat is displayed to monitor the room temperature - it turns on the boiler only when the set temperature decreases. Neva Suite 7218 is suitable for heating an area of 180 sq.m. A bi-thermal heat exchanger reduces equipment costs while retaining user-friendly features. The efficiency is 90%. The device can be converted to liquefied gas. It has a closed combustion chamber. The temperature of the coolant is 30-85 degrees. The electronic safety control unit with constant flame monitoring constantly checks the burner.

- Neva Lux 8224 heats 250 sq. M. m. of residential premises. Water cooling of the combustion chamber doubles its life. The microprocessor maintains the temperature level of the working environment with an accuracy of 1 degree. A copper heat exchanger is intended for the heating circuit; steel is used in the hot water supply from stainless steel. Added the ability to connect a computer to the control to simplify the diagnosis and configuration of equipment. Self-diagnosis information is displayed on the digital display with the output of parameters and errors.

The operation of the boiler is based on the “set and forget” principle. Once you set the parameters, you can not worry even when you turn off the power. During a long business trip or trip, the equipment is placed in minimum mode and saves gas. When the gas supply is cut off, the boiler switches to the circulation mode and drives the water along the circuit, preventing it from freezing.