In the Finnish sauna or Russian bath, the main room is traditionally a steam room. For the adoption of the thermal procedure, it is very important to maintain heat in the steam room and the washing room, which is achieved by additional thermal insulation of the bath. This is especially necessary in stand-alone buildings, in which it is often quite difficult to keep heat and it takes a lot of time and fuel to reach the required temperature. Warming in the steam room in the bath allows you to solve these problems.

Materials for insulation

Not so long ago, to save heat in the bathhouse, the steam room was insulated exclusively with natural heaters: clay mixed with sawdust, dry moss and tow. Their main disadvantages were fragility, susceptibility to putrefactive processes due to exposure to moisture.

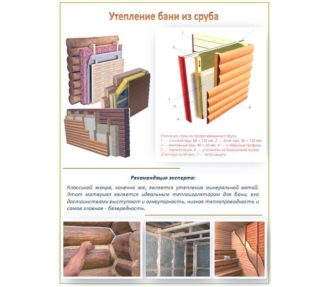

The thermal insulation for the bath in the steam room should have moisture resistant properties, low thermal conductivity and a long service life. However, not all heaters can be used due to the high temperature in the steam room. Most often, to reduce heat loss in the bath, basalt stone wool with a coating of aluminum foil is used, which does not emit toxic substances when heated. It is a non-combustible material and is able to withstand temperatures up to +700 degrees. It is successfully used for internal insulation of walls and ceilings. For floor insulation, it is recommended to use expanded clay or penoplex, which have low thermal conductivity, have moisture resistant properties and do not emit substances harmful to health.

What to consider when insulating a bath

Particular attention should be paid to the waterproofing device to protect the walls and insulation from moisture and condensation. The use of roofing material for protection against moisture in the bath is unacceptable, at high temperature in the room there will be a smell of resin. As vapor and waterproofing, foil materials should be used:

- kraft paper;

- isocom;

- Isolon

- penofol.

In the manufacture of foil kraft paper, the composition does not contain polymers, which allows the use of insulation in a steam room when exposed to steam above +100 degrees. Isocom, Isolon and Penofol are used in the washing room and rest room, where the temperature is much lower.

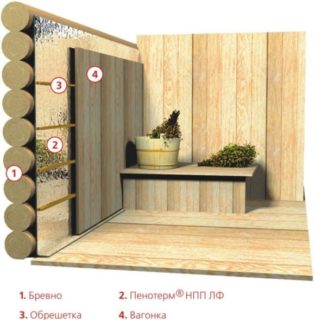

Before you start warming the steam room in a wooden bathhouse, you should inspect and remove the foci of fungus formation and rotting of the wood. It is necessary to treat the walls and elements of the lathing with a special non-toxic antiseptic, water-based, intended for baths and saunas. The steam room is insulated in the bath in the following sequence:

- A plastic film with lap joints of at least 10 centimeters is attached to the walls and ceiling and glued with tape for sealing.

- Ceiling and wall lathing is installed with a step corresponding to the width of the insulating material.

- Insulation is laid and fastened. If stone wool with foil is used, which is actually waterproofing, it remains only to seal the joints with adhesive tape with an aluminum layer. Insulation without foil must be closed with a waterproofing layer.

- The finish coating of the ceiling and walls is mounted on the crate.

Initially, the ceiling is insulated and closed, and then the internal walls of the bath. Lastly, work is done to warm the floor.Thermal insulation technology is quite suitable for saunas built of logs, bricks, foam blocks, aerated concrete and other building materials. Only the way of fixing the battens to the wall differs.

Warming the floor of the bath

The thermal insulation of the steam room floors in the bath is extremely important. It is recommended to use a moisture-resistant insulation, which does not lose its properties when temperature drops and has low thermal conductivity. The most appropriate insulation materials with similar parameters include:

- foamed glass;

- expanded clay;

- penoplex.

These heaters can be used when installing a wooden subfloor or on a concrete base. In the steam room, the flooring is made only of wood at a slight slope, which ensures the flow of water into the sewer. In the washing department, along with a wooden floor, a variant with ceramic floor tiles is quite common. Thermal insulation is laid out step by step according to the following scheme:

- A waterproofing layer of plastic film is laid on concrete or a rough field. Butt joints are sealed.

- Foam sheets are installed or loose insulation is poured.

- A second layer of waterproofing is being equipped.

- Flooring boards are attached to the lags. On a concrete base, a screed for floor tiles is poured and leveled over the insulation with waterproofing.

All wooden elements of the flooring are treated with an antiseptic before installation. The joints of the floorboards should be perpendicular to the sewer. The slope of the finishing coating for the water flow should be at least 1.5 degrees.

DIY steam room warming tips

It is not difficult to warm up the steam room on your own, if you follow simple instructions and tips. The steam room is a kind of thermos that keeps the heat inside for a long time. The lower the heat loss, the less time and fuel will be required to heat the steam room. A significant part of the heat according to the laws of physics goes through the ceiling, so if there is such a possibility, it makes sense to additionally isolate the steam room ceiling from the inside and from the attic.

It is not difficult to warm up the steam room on your own, if you follow simple instructions and tips. The steam room is a kind of thermos that keeps the heat inside for a long time. The lower the heat loss, the less time and fuel will be required to heat the steam room. A significant part of the heat according to the laws of physics goes through the ceiling, so if there is such a possibility, it makes sense to additionally isolate the steam room ceiling from the inside and from the attic.

The walls and ceiling should be leveled and sharp metal objects removed which during installation can damage the waterproofing layer during installation. It is best to use a waterproofing roll on a self-adhesive basis, the denser the insulation is pressed against the wall and ceiling, the less heat loss will be. It is advisable to install the waterproofing layer completely, in the entire room of the steam room, starting from the ceiling and ending with the perimeter of the bottom of the walls. At the bottom of the wall, leave a twenty-centimeter allowance necessary for joining the floor waterproofing.

For the design of the crate, a larch beam, which has low hygroscopicity and high resistance to decay, is best suited. The frame lath made of larch timber does not deform under the influence of temperature differences, changes in air humidity and has high mechanical properties.

Basalt stone wool with a layer of aluminum foil produced by the Rockwool Light Butts campaign retains 97% of the heat, does not absorb moisture, has good compressive and tensile strength, and has a long service life. To warm the steam room in the bath, it is unlikely to find a better material than stone wool.

To warm the floors in the steam room, it is preferable to use foam, which has low thermal conductivity and water-repellent properties. Sheets are easily cut with a knife, have docking grooves at the ends, eliminating heat loss. For greater efficiency during installation, you can use mounting foam for gluing joints. With equal success, it can be used for insulation of wooden and concrete floors.