Thermal insulation of the foundation is as important a task as the upholstery of wall and floor insulation. Frozen soil, especially in regions with harsh climates, does not protect the base of the building from water and cold, as a result of which the foundation is destroyed. To provide heat in the room and protect the house, thermal insulation works are carried out. You can do it yourself, it is only important to choose the right materials and installation technology.

Heat Insulation Requirements

The base of the building is constantly exposed to precipitation, temperature spikes, high loads. For this reason, special requirements are imposed on the choice of thermal insulation:

- low thermal conductivity;

- water tightness;

- high level of mechanical strength;

- resistance to temperature jumps;

- resistance to the formation of mold, fungi, damage from rodents and insects;

- incombustibility.

There are no strict requirements for vapor permeability, but it is recommended to take material with a low level.

Material selection

Mineral wool is not suitable for thermal insulation of foundations. This is due to the property of moisture accumulation and poor mechanical stability. It is better to take polymer insulation. The selection of material also depends on the estimate that is laid down in the project. Good insulation can be found among budget materials.

Styrofoam

Polyfoam is widely used in the creation of thermal insulation of buildings. It is characterized by low weight, regular sheet shape and ease of installation. On sale there are varieties with different densities and thicknesses that can be used in different fields. To insulate the foundation, the densest materials with a minimum thickness of 50 mm are selected.

The thermal conductivity of the material is more effective than that of wood, expanded clay or mineral wool. Polyfoam practically does not absorb water and does not shrink, does not deform over time. It features high soundproofing properties. The properties are also not affected by salt or chlorinated water, weak acids, soap liquids. It can interact with bituminous mastics, adhesive water-soluble agents.

PSB-S-50 and PSB-S-35

For slab foundations and foundations with great depth, PSB-S-50 polystyrene foam is used. It can withstand heavy loads and provides high-quality protection against swelling of the soil. Columnar and standard types of foundations can be insulated with material marked PSB-S-35. Operating temperature ranges are from -60 ° C to + 80 ° C. The dimensions of the plates are 1 × 0.5 m, 1 × 1 m, 2 × 1 m. The service life reaches 30 years.

Other varieties are not used due to poor density and fragility.

Extruded Styrofoam

There is a type of polystyrene foam, which is made by extrusion. The material obtained in this way is characterized by improved characteristics. It is stronger, waterproof, has a low level of vapor permeability and thermal conductivity. In extruded polystyrene foam, microorganisms do not form even with prolonged dampness.

Plates have a smaller thickness, but the effect of them is higher. For insulation in a temperate climate, a thickness of 40 mm is chosen, for installation in a cold northern climate, 60 mm is required, which is better to lay out in two layers of 30 mm. Laying is done vertically and horizontally.

Popular manufacturers are Technonikol and Penoplex. Warming the foundation with foam allows you to get a design life of more than 40 years.

Polyurethane foam

It has a durable coating without seams, is resistant to bad weather conditions and adverse effects. It also performs the functions of vapor and waterproofing, so that the process of insulation becomes easier and cheaper. The material has good adhesion to stone, concrete, brick, wooden blocks and other substrates.

There are two ways to apply polyurethane foam - pouring and spraying. In the first case, the work will be more difficult and costly, therefore it is rarely used. The second method is applicable for insulation of roofs, walls, ceilings and other parts of the structure. Before application, all components are mixed with air and the mass is sprayed onto the surface. The disadvantages include the need to purchase special equipment or rent it. The service life is 50 years.

Expanded clay

It has good characteristics, but due to the complexity of the process it is not used for thermal insulation of foundations from the inside. Also expanded clay cannot protect the basement from moisture, as it is not a moisture-resistant material.

Thermal insulation technology

Thermal insulation of foundations can be carried out at the construction stage or during the operation of a home. Before starting installation work, a check and preparation of the base is mandatory. It must be rid of cracks, debris and waterproofed. The effectiveness and durability of the result depend on the quality of the preparation.

Slab foundation insulation

Slab foundations must be isolated at the construction stage, as they are located under a layer of reinforced concrete.

The most time-consuming stage is excavation. The foundation is excavated until the soil or foundation freezes. If possible, it is better to hire special equipment to reduce the time.

The walls of the foundation are cleaned from the ground with a stiff brush. For 10 days, the foundation must be left so that all moisture is gone. Work must be carried out in the warm and dry season.

Step-by-step foundation warming algorithm:

- Inspection of the dried walls for damage. All defects are eliminated, dust must also be cleaned. If the thickness of the bumps exceeds 20 mm, the plaster is reinforced with a metal mesh. Then you need to wait for the plaster to dry and then you can proceed to the next stage of insulation.

- Waterproofing. It is better to take coating materials - bitumen mastic, polymers, rubber. To improve adhesion, a bitumen primer is also used. It is applied in a thin continuous layer and wait a day until it dries completely. Then, the mastic selected for waterproofing is applied.

- Mastic is mixed with water if the composition is too thick. It is applied with a wide brush or roller in a continuous uniform layer with a thorough treatment of all angles. The layer should not be too thin and not too thick. After the first layer has hardened, a second layer is applied. If the terrain is flooded with groundwater, a third coat should be applied.

- 5-7 days after the waterproofing dries, the insulation is installed. To do this, use special glue ALLFIX, Ceresit CT 83 or Titanium. Work is carried out from bottom to top in horizontal rows with the transportation of vertical joints. After applying glue, a plate is applied to the surface. Its location is checked by the construction level. Insulation plates for the foundation of the house are laid outside as densely as possible to each other so that joints are not visible. If the installation is two-layer, the plates are staggered. The joints of the two levels should not coincide, otherwise the effectiveness of insulation will fall.

- Fastening of the ground part using dowel nails or screw method.Fasteners need to be done after the solution has completely dried. Depth reaches 40-50 mm. After the dowel is hammered to the stop.

- Plastering the surface of the plates. Fiberglass reinforcing mesh is also placed. It is recommended to cut it into pieces and put on an overlap of 10 cm.

- Next you need to wait a day. After complete finishing leveling, and after drying of this layer, the surface is worked out with a grater with an emery cloth.

- At the end, the trench is covered with soil. Leave about 30 cm to the top. The soil should be compacted so that then the shrinkage is not so noticeable.

- A layer of sand 10-15 cm thick is laid on top.

- A waterproofing membrane is placed on top.

- The last stage is the arrangement of the blind area by pouring concrete screed.

In the case of using polyurethane foam, alignment and waterproofing are not necessary. After creating a trench and cleaning the walls from the ground, cracks are closed and delaminations are removed. After drying, you can apply insulation. When the material hardens, you can fill the trenches with soil and make a blind area.

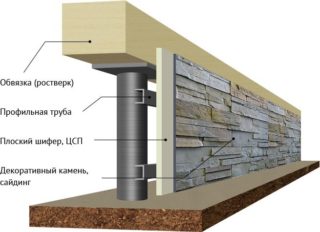

Thermal insulation of the column foundation

If the foundation is made in the form of pillars and piles, the insulation process will be different. To isolate the space between the grillage and soil, a structure is assembled that performs the function of a socle. It does not carry a load, and therefore, requirements for mechanical strength are not imposed.

Algorithm for pile foundation warming:

- Digging a trench between the pillars of the foundation. It should be narrow with a depth of half a meter. A third are covered with sand and gravel.

- Laying the frame of metal rods. Concrete mortar pouring.

- When the layer dries, a brick is laid around the perimeter of the foundation. Small vents remain in the opposite walls to allow for natural ventilation.

- After the masonry has dried, the selected insulation for the foundation is glued on the outside. Then they plaster it and put a reinforcing mesh.

- Falling asleep trench soil after complete drying. Tamping soil.

At the end, the decorative finishing of the frame base is done. It can be painted, applied with artificial stone or plaster, made with siding.

If it is not possible to put a brick clogging, a frame of bars or metal profiles is placed between the foundation supports. Wood must be treated with an antiseptic and dried. Bonding is done on metal corners and bolts with self-tapping screws.

Insulation board fixing

In the case of horizontal insulation of a private house, the plates can be laid in one or two layers. Material thickness - 50 or 100 mm. Thermal insulation is done after preparing the foundation pit and falling asleep on a sand pillow.

The algorithm for warming the foundation of the house outside:

- Tamping the sand layer in area and horizontal. The smoother the surface, the better the heat insulator lies.

- Laying film and heat insulation boards. In each subsequent layer, the plates are shifted so that joints do not form. The width of the shift is half the sheet.

- Installation of formwork around the perimeter of the foundation. A reinforcing frame of steel rods is mounted in it.

- Next you need to knead and pour concrete. You should wait until the layer has completely dried.

- Running the blind area. The sand is leveled and compacted. From the foundation you need to make a slight bias. Plates are evenly applied to each other, and a waterproofing membrane is placed on top. It should be overlapped by 10-15 cm.

- Sand backfill.

On this, the process of foundation warming is completed. If everything is done correctly and according to the instructions, the house will always remain warm.

When you can not insulate the foundation

If you refuse to warm the foundation, you can save money on building materials and the process of thermal insulation. Even before building a house, you need to decide whether insulation is necessary for the building. You can consult with professionals, and only then make a final decision.

The base can not be isolated in the following cases:

- The house is in a warm climate. Even in winter, there are no strong and prolonged frosts. In this case, the soil does not freeze, so the foundation can not be insulated.

- Uniformity of soil under the house. Tuition in this case will be uniform and the house will not give way.

- The underground part is below the freezing level. The heap of soil will not raise the foundation, but will only compress the side walls.

- Having good drainage around the house. Water is drained from the soil, so you can create good drainage and reduce heaving.

- There is high-quality thermal insulation of the blind areas.

- Before construction began, a thick layer of expanded clay or dry sand was poured under the foundation. This method is expensive, therefore it is practically not used.

The decision on the need for insulation is decided by the owner of the house. It is necessary to consult a professional, study the experience of building and warming houses in the region and note the features of laying the foundation.