Owners of accumulative or flow-type water heaters are constantly faced with the problem of scale deposits on the walls and bottom of the tank. To combat it, manufacturers offer various drugs, including special chemical solutions. In addition, folk savvy allows the use of various auxiliary means (citric acid, for example). One of the most effective techniques to get rid of scale in heating equipment is to install a protective anode for the boiler in them.

Why do I need an anode

To understand why a magnesium anode is needed in water heaters, you will need to consider the very principle of salt deposition (scale formation). The water entering the tank always contains more or less natural (soluble) salts. When heated, they react with the coating metal of the coil of the electric heater and parts of the storage tank of the boiler.

The material of the tank, made of corrosion-resistant stainless steel, under the influence of hard water changes its structure over time and gradually collapses.

On the other hand, there are metals whose chemical activity is so great that they “divert” a significant portion of the reagents onto themselves - the magnesium necessary for this is precisely related to them. The main purpose of the anode based on it is to protect stainless metal surfaces from salt deposits formed as a result of contact with water.

Since lime deposits and most types of metals have different expansion coefficients, over time the heating element is strongly deformed. The scale that forms on it reduces heat loss, and water heating slows down. As a result of this, the net power delivered to the load drops sharply. When installing the anode in a water heater, it is possible to get rid of all these shortcomings and significantly reduce the rate of electricity consumption.

Features of models of various manufacturers

The famous Slovenian company Gorenje conducted an experiment in which a modern anode was mounted on old water heater samples, for which magnesium was used. These experiments yielded positive results, which resulted in an increase in the efficiency of the devices by reducing the time for heating the water with a completely filled tank.

Another popular company, Atlantic, also tested with its own models. According to its results, an amazing result was obtained that showed a double increase in the service life of equipment.

Thermex company producing modern water heaters is known for the fact that its products are distinguished by long service life due to the presence of glass-ceramic coatings on the heating elements.

The first company to install a magnesium element in its products is Ariston, a company characterized by high quality indicators of manufactured equipment.

Types of anodes and principle of operation

In accordance with the material used in the manufacture, the anodes for boilers are divided into the following types:

- magnesium;

- titanium.

The titanium element, like magnesium, is also located to the left of the periodic table - it is able to attract cations to itself.

Principle of operation

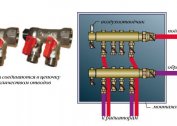

The basic principle of using a magnesium anode is the increased chemical activity of this metal, significantly exceeding the same indicator for steel parts. Due to this, the water around them is saturated with magnesium cations, which bind the oxygen formed during heating by the heating element. Due to this reaction, corrosion of the boiler elements is ensured.

An excess of cations leads to the formation of loosened scale due to a bond with carbon anions, which are subsequently easily removed from the structure. Formed in the form of an insoluble precipitate, a part settles with time on the anode itself.

The elements of the boiler fail, since over time there is a consumption of the magnesium anode, which gradually wears out due to corrosion. With intensive use of a home boiler, taking into account the low quality of tap water, you should be prepared for an urgent replacement of an element that has expired.

Magnesium Anode Replacement

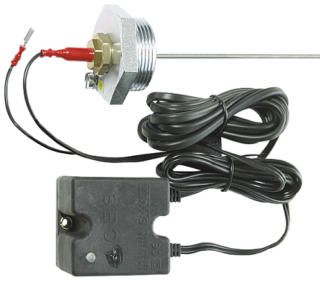

The magnesium anode looks like an ordinary metal pin with an alloy deposited on it with a thickness of approximately 15 millimeters. At the end there is a threaded rod made on the basis of metal. The average length of the pin is approximately 140-660 mm, and the studs are approximately from 14 to 25 millimeters.

Technical serviceability or malfunction of the magnesium anode is easily controlled visually. When inspecting it, it should be borne in mind that severe deterioration will significantly affect the performance of all heating equipment. All manufacturers of these elements have their design is different, and sometimes differs quite a lot. This fact forces many consumers to purchase anode type, which is specifically designed for this model of water heater, to replace.

For long-term operation of the equipment (more than 15 months), it is recommended to proceed in the following order:

- Disassemble the unit to a state that will allow free access to the site being examined. To do this, you need to unscrew the screws that secure the cover of the device with a magnetic screwdriver, remove it or move it to the side.

- When the length of the wires is enough, you need to remove the thermostat and the sensor from the tube (it is fixed to the contacts). Otherwise, you will have to disconnect the power cable and only then remove the thermocouple.

- Using a wrench, you need to unscrew the block flange, and then remove the heater along with the anode.

- Using the pliers, you should grab the worn element or the remainder in the form of a thin rod and unscrew it from the socket.

- If traces of severe damage are found, this part will have to be completely removed and replaced with a new product.

The boiler comes with a special tool (hairpin), through which the anode is twisted out of the threaded hole in the heater's flange.

When dismantling, it is important to pay attention to the fact that the size and the total number of mounting bolts depends on the specific modification of the boiler. On Ariston, for example, there are fasteners having five 10 mm turnkey nuts, or one metal spacer bar fixed on one 14 mm nut.

Wear criteria

There are several easily identifiable indicators that it is time to completely clean the unit and then change the magnesium anode:

- when the household appliance is turned on after some time, protection is triggered, which is explained by the presence of a thick layer of scale on its heating element;

- the previously observed water heating is completely absent when the boiler is operating normally;

- the equipment case begins to periodically “beat” with electric current, which is a sign of a violation of the quality of insulation due to the destruction of individual parts.

One of these manifestations is an excuse to immediately stop the operation of the boiler and begin to research it. Only a thorough study of the state of the electric water heater and the anode allows us to make a final conclusion about the need to replace them.

Specialist advice

The average life of a typical magnesium cell is two years. However, in special cases, this figure can take other values - 1 year or 3, most often depends on water quality. This applies only to models of water heaters equipped with steel flasks.

In the domestic market, boilers equipped with an internal stainless steel flask are also represented. Given all these points, experts recommend paying attention to the following details:

- Whenever possible, you should check the operation of the boiler unit by ear.

- If hissing is heard during heating, the contact covered with an insulating coating has worsened at the attachment point of the heating element.

- After some time, it is advisable to look into the interior of the boiler. Having found a 50% destruction of the anode, you need to look for a replacement for it.

- You should try to clean the boiler more often than indicated in the product instruction manual.

It is not allowed to start the heating unit without anode.