To install a brick or metal stove in your home, you need to familiarize yourself with the known varieties of these products. Self-assembly of furnaces is possible only if they are carefully studied. You will also need to master the basics of assembling electrical and masonry brick structures.

Advantages and disadvantages

Advantages of modern brick stoves built in a house or in a bath:

- Such a design, unlike a metal one, has a large heat capacity.

- Surfaces heat up to not too high temperatures - are safe in operation.

- Brickwork looks beautiful in a wooden bath on a background of wood trim.

After the brick oven is well melted, the whole family can wash in the bath for about 5-6 hours. With a metal structure, this is not possible, since it cools down in just a couple of hours.

To assemble a metal structure, you will need an expensive welding machine, on which you still need to be able to work.

The disadvantage of brick products when compared with iron is the great complexity of manufacturing and significant costs for the wage specialist masonry. In addition, unlike steel structures, before installing the stove in the cottage with your own hands, you will have to make a foundation under it. This further increases the material and time costs for its manufacture and high-quality installation.

Criterias of choice

The efficiency of heating of living spaces and ease of use depend on how well the stove design is chosen. A responsible approach to this procedure is required, taking into account the following points:

- As a material, it is preferable to choose chamotte brick.

- The dimensions and thermal power of the future design should correspond to the heated area, which provides the desired indicator for heat transfer.

- It is important to choose the shape of the furnace structure correctly, taking into account the fact that its sidewalls give 3-4 times more heat than the front and rear walls.

- If it is necessary to heat two rooms at once, choose a narrow and long construction, which is built into the wall between adjacent rooms.

Another important condition is the competent choice of the installation site of the fireplace stove within the premises. Taking this factor into account will allow you to operate the oven with maximum efficiency, using for cooking, for example. You should not choose a bulky stove with a large margin of power, since part of the heat in this case is spent uselessly.

Room preparation

The place for the heating structure is selected at the design stage of the frame structure, which ensures the correct installation of the stove within the building. From a properly selected site, heat is evenly distributed throughout the house. A competent approach to solving this issue will also allow you to determine the place and power of the foundation being built for the furnace.

The place for the heating structure is selected at the design stage of the frame structure, which ensures the correct installation of the stove within the building. From a properly selected site, heat is evenly distributed throughout the house. A competent approach to solving this issue will also allow you to determine the place and power of the foundation being built for the furnace.

In construction practice, the installation of furnaces is implemented in one of the following ways:

- For the stove and for the home, a common foundation is being prepared.

- The base for the furnace structure is made separately from the foundation of the structure, and a distance of at least 150 mm is left between them.

The second option is chosen if the dimensions of the furnace and its mass are not very large, the shrinkage for it and for the walls will not differ much. The presence of a common foundation in this situation leads to deformation and destruction of the structure.

Features of installing a metal furnace

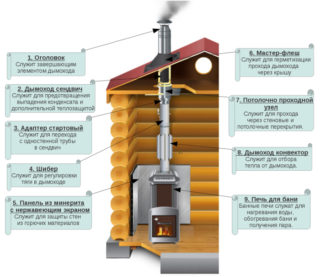

Step-by-step instructions for installing the stove in a country bath can be presented as follows:

- Selects the type of base, which in the case of lightweight metal construction may be completely absent.

- According to the instructions, there is an optimal place for placement, guaranteeing uniform heating of the entire room.

- On the selected site, the structure itself is installed, after which a chimney is attached to it.

If there are several rooms in the bathhouse according to the project, the stove installed on the wooden floor in the bathhouse is located at the crossroads of the walls that separate them.

When placing the furnace near the entrance to the bath, the radiation emanating from it creates reliable protection in the form of a thermal curtain. When installing the oven, it is important to ensure that the furnace door is correctly positioned to prevent burns. Part of the flooring in front of it is necessarily covered with heat-resistant sheet material.

Brick finish

For the protective finish of a metal furnace, a high-quality refractory brick with voids in its structure will be required. It is allowed to use finishing material with a relief pattern or just a smooth front surface. Its total amount is calculated taking into account the size of the iron furnace itself, as well as part of the area around it to be protected.

It takes into account the need to prepare the base for the stove on wooden floors, equipped from one or 2 rows of continuous masonry. If the chimney brought out is supposed to be laid out of a brick, it should also be taken into account in the calculations. It is important to decide on the method of laying brick blanks, which are most often placed on the edge, which saves on consumables. For greater thermal return, a method of laying in full brick is proposed.

Chimney installation and requirements for its height

When installing the chimney, you will need to fulfill the following requirements:

When installing the chimney, you will need to fulfill the following requirements:

- The vacuum inside the smoke exhaust pipe must be at least 5 Pa. For this, its height is selected at least 5 meters.

- The upper section of the pipe is located above the level of the wind support. Its diameter should not be less than the outlet pipe of the furnace itself.

To connect to the chimney, stainless steel transitional blanks with a thickness of at least 0.8 mm are used. When constructing a capital chimney, based on a powerful foundation, it is allowed to use a special nozzle made of stainless steel. In this case, the temperature of the exhaust gases cannot exceed a certain value indicated by the manufacturers of furnaces.