In the manufacture of foundations for any construction projects, enclosing formwork is necessarily used. It sets the outlines of the concrete base, corresponding to the pouring pattern, and its exact geometric dimensions. Polystyrene foam formwork is one of the possible options for enclosing structures, increasingly used in construction.

Advantages and disadvantages

The use of modern fences used in the manufacture of foundation foundations is justified by the presence of a number of advantages:

- quick installation of the foundation by combining several operations at once: the load-bearing elements and high-quality thermal insulation are mounted in one technological cycle;

- profitability, due to the low cost of the material and the lack of costs for its dismantling;

- the possibility of obtaining a flat surface of the walls of the foundation being built, which reduces the consumption of concrete mortar;

- increasing the strength and reliability of the structure due to the fact that fixed formwork made of expanded polystyrene becomes part of the foundation;

- tightness of the enclosing structure, eliminating leakage of water and concrete mix - is achieved due to the high density of the installation of plates;

- protection of structural elements from the adverse effects of the environment and biostability, extending the life of the building.

The use of fences based on PPS allows you to protect the foundation from frozen soil, low thermal conductivity (only 0.032 W / m) significantly reduces heat loss. The advantages of polystyrene formwork for the foundation include the possibility of obtaining a closed contour of the fence, due to this it is possible to reduce losses by another 11 percent. At the same time, the cost of fixed formwork is approximately 20 percent lower compared to standard designs.

The disadvantages of such structures include:

- exposure of the foam to ultraviolet radiation;

- significant time costs for arranging a separate waterproofing (especially for formwork) and for the phased pouring of concrete mix;

- the need to reinforce PPP products using transverse reinforcement.

The disadvantage of using this material is considered to be insufficient insulation of the lower layers of the foundation being poured.

Types of formwork

Before starting installation work, it is advisable to familiarize yourself with the existing options for fixed barriers used in construction practice. The main feature by which products are classified is the material of manufacture:

- polystyrene foam;

- fibrolite;

- arbolit.

The choice of a suitable option is determined by the complexity of the future building and its design features. Gas-filled polystyrene stands out among its analogues for its strength and lightness. When installing it, there is no need to attract heavy construction equipment.

The fiberboard is made on the basis of two components:

- wood shavings, giving the formwork elements characteristic fibrousness;

- inorganic binder responsible for fiber adhesion and material strength.

The main advantage of fiberboard formwork is its resistance to temperature fluctuations.

Arbolit includes two components: wood shavings and concrete mix, which are kneaded in the form of blocks of a given shape.In the latter, small voids are provided, during installation reinforced by fittings, and then filled with mortar. Despite the attractive strength indicators, arbolite products have a number of disadvantages, including low thermal insulation and high cost.

You should also pay attention to the mixture of wood chips with concrete or chip cement, distinguished by its excellent soundproofing properties.

According to the features of the structure formed by the elements of the fencing, the known types of fixed formwork from PPS are:

- cellular;

- classic

- modernized.

The first variety is a lot of hollow blocks, fastened together like a children's prefabricated designer. The cavities formed in this case provide free filling with a solution of the internal spaces of the formwork. To reinforce the fill, vertical and horizontal elements are used, fastened inside the PPS cells. Such blocks are usually manufactured on an industrial scale.

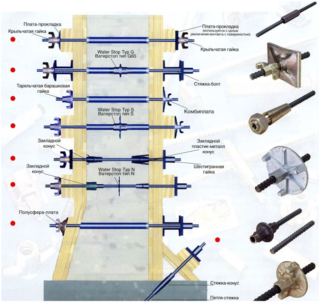

Classical designs are presented in the form of familiar shield fences installed on both sides of the poured space. Between themselves, the PPS plates are additionally bonded with metal ties. Improved fences practically repeat the previous version, but instead of typical metal ties they use metal or wood beams. To increase the strength of the structure, they also use struts and stops.

Features of installation for the strip foundation

Strip foundations are among the most popular foundations built with the independent construction of houses and other buildings. In their manufacture, the preparation of the pouring site is of particular importance, since the reliability of the entire structure depends on its quality. Formwork for a strip foundation made of polystyrene foam is quite simple to equip, which does not exclude the need to take into account the following nuances:

- It is recommended to fill the solution in such a design in layers, which ensures a smooth increase in the load on the walls;

- the cavities in the block are filled with a solution according to the same procedure as the main foundation mass;

- the reinforcement used to strengthen the foundation is laid in such a way as not to damage the working surfaces;

- binding is usually carried out inside block elements;

- there is no need to dismantle the PPP slabs, since they remain in the structure as heat insulation elements.

If necessary, non-removable polystyrene formwork is further strengthened by means of spacers. At the same time, it is important to preserve the foundation foundation configuration unchanged in the project.

Do-it-yourself fixed formwork

For independent arrangement of fences from the faculty for foundations of any type, you will need to familiarize yourself with the order of the operations performed in this case. Due to the ease of the material used, all procedures for its arrangement are carried out by one person without outside help. The declared advantages of products based on PPP allow you to act as follows:

- A sketch of the strip foundation is made with an exact indication of the location of the individual elements.

- Prepared blanks of proprietary PPP formwork. When choosing them, the need to use several rows of structures (up to 4) is taken into account.

- Measures are being taken to link the formwork elements to the flooded space, for which small pieces of reinforcement are used.

- During the installation of fixed structures based on PPP, special attention is paid to the density of their joining - no gaps should remain.

- When carrying out installation work, do not pour all the concrete at once. First, partial pouring is carried out, after which a pause is made for 3-4 hours, sufficient for the solution to shrink.After this, the remaining volume of the concrete mixture is added.

When constructing monolithic bases for casting fences, special shaped panels are used. The individual components are connected by means of coupling bolts and form a working area, which is then poured with concrete mortar. When working with them, it is necessary to take into account that these products have different dimensions.

What attention is paid to

When working with foam blanks, it is recommended to pay attention to the following features of the arrangement of formwork:

- the height of removable block structures averages 3.3 meters;

- width ranges from 0.25 to 2.4 meters;

- the exact dimensions of the block formwork are selected based on the individual characteristics of a particular structure;

- the foundation also needs to be phased in, due to the instability of the building envelope.

Even with four-row stacking of blocks using reinforcing reinforcement, casting needs pauses arranged between several approaches. This time is enough for the solution to completely settle and condense well.

When installing fixed blocks made of polystyrene foam, great attention is paid to the area of their docking. Separate elements of a branched foam construction are interconnected with great care, which allows you to get the most even surface pouring.