Even with a high-quality heating system, the finished structure does not always retain heat qualitatively. In order to eliminate cold bridges and protect against heat loss, the house is insulated from the outside. Before starting work, it is necessary to select materials, study the technology that is optimal for a particular building.

Thermal insulation materials for external insulation

Regardless of the type and quality of building materials can not completely retain the heat inside the house. Voids in the rows of timber, heterogeneity of brick and aerated concrete blocks, joints in panel structures and air cavities must be closed. External thermal insulation with the correct use of materials will reduce the cost of heating and air conditioning at home, will ensure a comfortable temperature in the off-season.

Expanded polystyrene

Expanded polystyrene is characterized by a coefficient of thermal conductivity of 0.028-0.034 W / (m * K) depending on the density. Polyfoam is available in slab and bulk form. The cellular structure provides, in addition to thermal protection, noise insulation of the building. Budget material - durable, does not absorb moisture, does not burn.

Extruded Styrofoam

The heat insulator is moisture-proof, which allows you to insulate the basement floors and the foundation. It has the appearance of plates that are laid on a vapor barrier membrane. Installation is carried out on the wall, previously cleaned of debris and leveled. Plates are attached to glue or anchors with mushroom caps.

Extruded polystyrene foam is subject to burning. The second minus of the material is the obligatory alignment of the wall to prevent the formation of voids, where moisture accumulates, and fungi appear.

Stone wool

Basalt insulation is environmentally friendly, does not irritate the skin. Thanks to the fibrous structure, mineral wool retains warm air and qualitatively protects the structure from cold. The low coefficient of thermal conductivity provides a minimum layer thickness during installation - only 30 mm. Installation is carried out by gluing to a wall of brick or concrete, followed by fixing with dowels.

Polyurethane foam

Thermal insulation material is available in the following forms:

- Thermal panels with decorative finishes in the form of tiles or chips and a bearing base made of waterproof plywood or OSB. Depending on the type of insulation, the plate is two-layer (polystyrene foam) and three-layer (polyurethane foam). Fastening is carried out open (anchors and dowels) and closed (own locks).

- PPU. Foam provides evenness and seamlessness of the thermal insulation coating on uneven walls. Two-component material is sprayed from professional stations. One-component polyurethane foam is applied from an aerosol can in 1-2 layers.

Foamed foam polyurethane is not suitable for a "wet facade" - it can come off when loaded.

- Polyurethane foam

- Stone wool

Thermal insulation technology

The building codes state that it is better to insulate a private house or cottage on the outside in two or three layers. Three-layer thermal insulation provides an outer layer of structural materials. The two-layer method eliminates the insulating properties of the external finish.Self-warming of buildings begins with the choice of a method of protection against heat leaks.

The building codes state that it is better to insulate a private house or cottage on the outside in two or three layers. Three-layer thermal insulation provides an outer layer of structural materials. The two-layer method eliminates the insulating properties of the external finish.Self-warming of buildings begins with the choice of a method of protection against heat leaks.

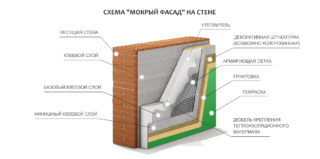

The wet facade system

The wet façade technology prevents dew point formation and saves money. Insulation works are carried out according to the following algorithm:

- Elimination of surface irregularities. Provides a tight pressing of the insulation to the wall, eliminates the risks of condensation and mold.

- Wall treatment. Cement, silicate or epoxy plaster is applied with a layer of up to 5 cm.

- Painting the plaster layer. It is carried out after the wall dries.

- Fastening of support strips for even thermal insulation.

- Installation of insulation boards on a solid wall. The material is laid on the bar and fastened with dowels. 4 elements are in the corner parts, 1 - in the center. The second method is fixing with adhesive solution to a pre-installed stack.

It is allowed to carry out the insulation of the capital surfaces of the house with foam or foam. The advantages include ease of laying, and the disadvantages are the labor involved in pre-leveling the surface and repairing cracks.

The technology of the "wet facade" is the best option for the restoration of buildings for the construction of which brick was used.

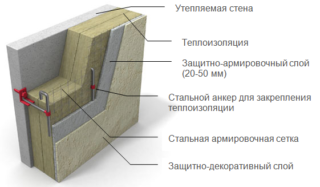

Warming in the form of three leveling layers

The well method allows the use of stone durable insulation for all types of exterior walls. An additional ½ brick construction is lined up in front of the main surface indented. A kind of emptiness appears between the walls, which works like a "thermos". From the inside, the “well” is reinforced with mesh or steel anchors.

The technology of three leveling layers has several features:

- Control the distance from the main wall to the decorative. If it is small, the percentage of heat transfer from the inner surface to the outer one increases, and the drying of the condensate is prolonged.

- Additional use of insulation - polystyrene foam, expanded clay, stone wool or foamed polyurethane. The material is attached to the main wall, behind it is a well, and then - a decorative design.

- Arrangement of ventilation. The design must be purged to prevent moisture formation.

- Lack of gaps in the masonry. Otherwise, the brick layer will damp and collapse, and the heat insulator will get wet.

To prevent the formation of a “cold bridge”, purchase an anchor with a small cross section or install a mesh made of plastic.

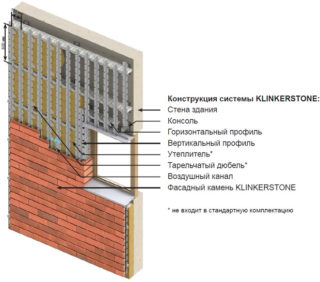

Ventilation Facade System

The ventilated facade provides high-quality insulation and an aesthetic appearance of the structure. For work, an artificial slab stone, wooden siding or lining is suitable. The principle of creating thermal insulation resembles a well, but is implemented differently:

- Installation of vertical metal rails in increments of the width of the insulation.

- Fixing the heat insulation plate in 5 places on the dowels.

- Shelter of the outer part of the insulation with a membrane that protects against penetration of steam and moisture.

- Fastening decorative panels to complete clips indented 8 cm from the base layer.

The dew point is located on the inside of the facade panel. The gaps between the lining ensure normal air circulation and eliminate condensation.

As a vapor barrier, it is allowed to lay a plastic film.

Features of technology selection

Before starting the preparatory work, it is necessary to choose a method of creating thermal protection. Selection is carried out with reference to the wall material:

- Expanded clay, brick and reinforced concrete structures are insulated in any way.

- Wooden beam - two-layer or three-layer walls are equipped with an air ventilation layer.

- Frame type of buildings - if there is cladding, a three-layer wall is made with central thermal insulation or an air gap (ventilated or non-ventilated).

- Block cellular concrete - a two-layer wall is lined with brick. The interlayer may be unventilated or ventilated.

For external windproof sheathing, roofing material, gypsum board, profiled sheets, siding can be used or warming of a wooden house with penoplex followed by finishing.

The procedure for preparing the external walls for laying thermal insulation

Before performing the insulation, the foundation is prepared. The works provide reliability, efficiency, durability of the insulation system and include:

- Dismantling of old finishes and surface cleaning. When installing ventilation facades, the wall can not be cleaned.

- Alignment of the base or facade. With minor thickness errors, a 2-layer deep penetration primer is applied to the wall. Irregularities of more than 2 cm are covered with cement mortar with a further primer.

- Alignment of the wall under the ventilated facade with brackets.

- Installation of beacons, on which the insulation will be aligned. Elements are mounted plumb and checked by level. For the manufacture of lighthouses, wooden or aluminum slats are used, which are fastened with self-tapping screws or anchors.

Insulate the outer wall only after preparation. Otherwise, thermal insulation will quickly lose its properties or will not be effective initially.

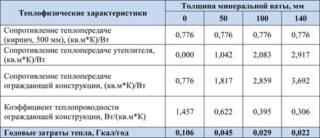

Selection of insulation thickness

SP 50.13330.2012 establishes a complex algorithm for calculating the thickness of the material. For calculations, it is better to contact specialists, but you can use the online calculator or special offline programs.

In standard conditions, take into account the type of wall material:

- brick - 210 cm;

- expanded clay concrete - 90 cm;

- wooden - 53 cm;

- aerated concrete - 44 cm;

- mineral wool - 18 cm;

- expanded polystyrene - 12 cm.

After clarifying the thickness of the wall material, it is necessary to verify the regulatory requirements and calculate how much insulation to add. For wet facades, the plaster layer is taken into account, for ventilated facades - the distance of the air gap. Interior decoration is also taken into account.

Stages of installation of insulation

You can consider the technology of external thermal insulation using the example of laying extruded plate polystyrene foam or polystyrene on a brick or concrete surface:

- Installation of metal profile rails on the lower part of the basement or facade.

- The application is close to the plate against the wall and a reference point for plumb lines lowered from the roofs.

- Adhesive insulation on dry mixes or polyurethane adhesive.

- Checking the evenness of the first plate and laying the rest. The subsequent layer is shifted horizontally by 1/3 or ½ of the previous one.

- Adjustment of thermal insulation. Corners are cut out on the sides. For durability of fixing plastic expansion bolt shields are used. They are placed on two adjacent corners, corner and center points.

- Closing joints. Joints may be putty coated, glued with metal tape or filled with heat-insulating foam.

Before applying the cladding, plastic mesh is installed and plastered.

With the right choice of material and technology, external thermal insulation is easily installed with your own hands. In the process of selecting the thickness of the insulation layer, it is necessary to be guided by the requirements of the standards.