For heating residential buildings in the private sector, solid fuel boiler equipment has traditionally been used. It is not inferior in its popularity to gas units equipped with a gas holder, and even surpasses them in terms of operational safety. Therefore, it is important for many owners of country houses to understand what a pellet boiler is and how it works.

What is a pellet boiler

At its core, a pellet boiler is a type of solid fuel unit designed for a special type of fuel (wood briquettes) and characterized by partial or full automation of the work process. The fundamental difference between this equipment and other samples is the autonomy of the action - the ability to function almost without the intervention of the owner. A feature of units of this class is a higher efficiency value, achieved due to the high heat transfer of fuel briquettes and due to the design features.

In the domestic market, pellet boilers are represented by several versions:

- models designed only for pellets and not capable of long-term operation from other types of fuel;

- combined units in which both firewood and coal are loaded;

- samples that work well on almost any kind of biomass.

Modern pellet boilers are reliable and safe units that are in constant demand among the owners of suburban farms.

Features of the device and principle of operation

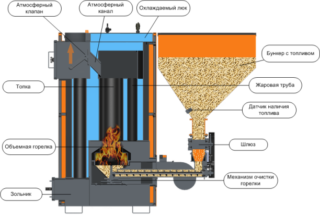

The typical design of a pellet boiler for heating a private house consists of the following main components:

- furnace module;

- convection zone;

- ashpit.

In addition, the system contains a special mechanism for feeding wood pellets into the combustion chamber, as well as a hopper for storing them. In most models, the procedure for adding fuel is dispensed with without human intervention and involves their automatic supply to the place of use.

The screw method for refueling pellets for boilers together with the ignition mechanism ensures their rapid combustion. This allows us to classify pellet heating equipment as technologically advanced.

The system includes a built-in fan, forcing air into the combustion zone. Its presence significantly increases the efficiency of solid fuel utilization, and also accelerates heat transfer processes. For reliable ignition of the unit, it is required that the furnace first burns out well. After that, the unit enters the operating mode, during which hot gases are formed, discharged through the chimney to the outside.

Another feature of the equipment is the large losses in the output channel of the spent product (up to 95 percent). This is considered a drawback to the design used.

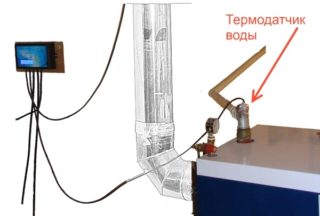

In the boiler itself, the air flow intensity is automatically regulated, taking into account the optimal parameters of its functioning. If necessary, a manual mode for controlling the operation of the system produced from the remote control, remote from the furnace at a considerable distance, is possible.

A distinctive feature of the pellet unit is the continuity of fuel supply up to a certain point, until the maximum temperature in the system is reached.When it is interrupted, it is possible to resume the operating mode only after the temperature in the circuit drops to an acceptable value.

Advantages and disadvantages

To get a complete picture of the operation of solid fuel heating boilers, it is not enough to know their operating principle and device. To do this, you need to familiarize yourself with the advantages and disadvantages. The following characteristics are attributed to the positive aspects:

- increased indicator of profitability, eliminating the need to create large stocks of firewood or coal;

- high efficiency, which can only be achieved with the operation of gas boiler equipment;

- high calorific value of the starting material;

- the cost of solid fuel is rather low in comparison with the thermal effect;

- absolute safety of operation of equipment of this type;

- the ability to fully automate the workflow;

- the ability to dispense with the control of the state of the system without human intervention, since the built-in automation controls the fuel supply and temperature conditions of the system;

- durability and reliability of equipment in general.

The advantages of the systems include the absence of unpleasant odors and harmful smoke that is harmful to human health. According to a number of features, pellet type constructions belong to the category of environmentally friendly and attractive for the modern user.

Units of this class have disadvantages that must be taken into account when choosing a specific sample of heating equipment:

- the high cost of components manufactured specifically for the repair of units with their own hands;

- the difficulty with the purchase of combustible fuel (pellets), due to poor setup of the process of production of wood pellets;

- high energy consumption associated with additional electricity costs for process automation.

A feature of the operation of the equipment is the need for a new adjustment of the heating system after it is forced to stop for more than 10 hours. The difficulties of handling pellet boilers include the user's constant concern about the continuity of power supply from the current source. In order not to depend on unexpected power outages, it is recommended to install a stand-alone generator.

What to look for when choosing

The modern pellet boiler is a cast-iron or steel structure equipped with a hopper of a sufficiently large volume - up to 500 liters. The indicated dimensions of the pellet accumulator are found only in samples with a capacity of more than 50 kW.

When choosing a suitable boiler model for its main reference point, as a rule, its price is taken. Heating equipment of this class costs at least 200 thousand rubles. This indicator varies depending on such characteristics as power, functionality, as well as features of a particular sample.

Correctly choosing the right instance of boiler equipment will help accounting for the capacity declared by the manufacturers, it is reduced to the unit area of the premises, expressed in square meters. m. With its increase, the dimensions of the loading hopper, as well as the dimensions of the entire device, increase. Due attention when choosing a suitable product sample is given to the quality of the metal of which it is made.

Homemade boilers in terms of efficiency are inferior to prefabricated plants, but they surpass them in terms of low cost and reliable operation. This can be achieved by increasing the thickness of the metal structural elements.

It is important to remember the total weight of the unit so that the prepared base can withstand it.

Pellet boiler options

You can familiarize yourself with the options for manufacturing pellet boilers in more detail, if you consider the rating of several models that have received high marks from an ordinary buyer.

The Sunsystem V2 25KW / PLB25-P product belongs to high-tech and fully automated equipment samples. It is equipped with a water circuit and is intended for heating private buildings with a small usable area. Characterized by high-quality assembly, the model has a removable hopper with connectors that allow it to be mounted from different sides. It has a modern design and has the auxiliary option of self-cleaning and a built-in timer.

The Pelletron 40 CT model is characterized by simplicity and versatility in operation and maintenance. Understood control allows people who are not at all familiar with this type of heating equipment to use it. The radiators and boilers included in the kit, as well as the elements of the heated floor, can be installed in other heating systems.

The considered models on one load are able to work for at least 24 hours. For supplying pellets and air to the burning site, they have two controlled mechanisms. To clean the storage tanks, a moment is selected that occurs immediately after burning the next load. Electric heating elements are used as heating elements in these samples. They are distinguished by a relatively high efficiency and a high level of heat transfer. The negative sides of the models include the ability to work only on special, "white" pellets.

In third place is the fully automated Kupper Ok 20 product with a pellet burner. It has an attractive price without losing quality. Users are attracted by the increased productivity, which allows servicing residential premises with an area of up to 250 m2.