Gas convection boiler is a standard type of heating equipment. The unit heats the room, water for domestic and household needs. Smoke is removed through the chimney after the initial combustion of the fuel, the high temperature in the furnace prevents condensation from forming on the inside of the boiler. Powerful equipment requires forced air supply and removal of combustion products, since liquefied and natural gas are explosive substances.

Device and principle of operation

In convection units, the temperature of the return and supply branches differ slightly. This prevents the appearance of drops of water with dissolved acids on the parts of the heat exchanger, chimney and furnace. With radiator heating, the supply line heats up to + 80 ° C, and in the return line - up to + 60 ° C, which eliminates condensation. Sometimes an automatic mixer is placed to mix the liquid of the supply circuit into the return line.

In convection units, the temperature of the return and supply branches differ slightly. This prevents the appearance of drops of water with dissolved acids on the parts of the heat exchanger, chimney and furnace. With radiator heating, the supply line heats up to + 80 ° C, and in the return line - up to + 60 ° C, which eliminates condensation. Sometimes an automatic mixer is placed to mix the liquid of the supply circuit into the return line.

Work begins with a gas supply and the operation of the piezoelectric ignition element. The spark ignites the igniter, burning all the time of operation, the attenuation of the device threatens an explosion. From the igniter, the base burner is switched on, which heats the energy source to the required temperature. Automation shuts off the main burner when the indicator is reached, and a drop in the value leads to the repeated inclusion of the flame.

The burner and heat exchanger determine the type of boiler. The first element is made of stainless steel, and regenerators and recuperators are made of materials:

- stainless steel;

- copper;

- carbon steel.

The disadvantage of the convection method is the irrational use of heat. If you set the low temperature mode, cooling of the final products leads to condensation in the chimney.

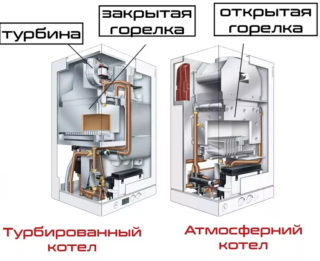

Types of convection boilers

According to the type of smoke exhaust distinguish between turbine and chimney types. Forced traction devices are installed in boilers where air enters from the street and is removed outside the building. The procedure is provided by mounted fans through small diameter ducts. Organized removal makes it possible to put the boiler anywhere in the house and divert products through horizontal pipes.

According to the type of smoke exhaust distinguish between turbine and chimney types. Forced traction devices are installed in boilers where air enters from the street and is removed outside the building. The procedure is provided by mounted fans through small diameter ducts. Organized removal makes it possible to put the boiler anywhere in the house and divert products through horizontal pipes.

Chimney used:

- separate view;

- coaxial option.

Natural draft involves the intake of oxygen from the room where the boiler is located, and the removal of combustion products without the use of fans.

Depending on the number of connected heating branches, boilers are:

- single-circuit;

- double-circuit.

The choice of boiler type depends on the needs of the house and existing heating equipment. If there is a central hot water main, a single-circuit boiler is installed. The double-circuit unit works so that while the liquid heats up in the water supply, the energy source in the system cools down. Such a boiler will not cope simultaneously with heating and heating the liquid if the demand for hot water is large.

Ukrainian manufacturers produce dual-circuit equipment in which the additional circuit has the shape of a coil and is located around the heat exchanger. This type of water heating is not regulated automatically, and hot liquid is obtained only during the heating season.

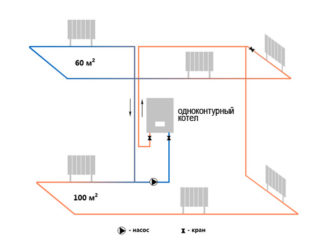

Single-circuit

This type is used only for heating the room, and if you need to get hot water, a capacitive indirect water heater is connected. A gas convection boiler heats the structure by heating the energy carrier in the heat exchanger.The heated liquid enters the piping system and batteries, gives off heat and returns along the branch to the regenerator. The heating and advancement of water in the heating main is repeated.

Radiators are installed sequentially, while saving pipes. The first batteries in the path of the energy carrier are heated more strongly, the latter do not receive the required heat. In the final radiators, the number of sections is increasing to increase heating. Sometimes control fixtures are placed on the first heaters to limit the temperature.

The movement of energy occurs due to the difference in pressure in the hot and cold state. The second option involves the use of a circulation pump.

Bypass

In this embodiment, the heating branch and the DHW circuit are connected. The heating line forms a closed system, during operation of which hot liquid does not enter the water supply. When the water supply is opened, a valve is activated that directs water to the DHW system, but blocks the flow of the coolant into the heating circuit. After closing the tap, the valve switches, water enters the heating system.

In a double-circuit boiler, a combustion chamber is used:

- open

- closed.

In a unit with an open chamber, air is naturally pumped out of the boiler room. Equipment is not installed in other rooms, because when there is insufficient ventilation in the room, there is a lack of oxygen and accumulation of combustion products. Such boilers cost less and are used where there are separate boiler rooms.

In boilers with a closed chamber, air is supplied and forced out, so there is no danger of smoke in the room. A storage boiler works better with a boiler than a flowing boiler if the pressure in the water supply system weakens or disappears. The cost of a unit with a boiler is higher than similar equipment with a flowing type of heating fluid.

Installation methods

Floor or wall option is selected depending on the power and the heated area. Wall-mounted units provide heating of the room no more than 200 m2 and differ in performance not more than 14 l / min. If the needs of the building are higher, a floor unit is installed.

Floor

The equipment is mounted on the floor or on a special foundation, and piping elements are purchased separately from the boiler.

Types of units are produced:

- fire tube steel boilers;

- cast iron gas equipment.

The first type has increased power and high efficiency. The heat exchanger is made in the form of a cylinder with a welded joint, contains steel manifolds for the movement of water. The gas combustion chamber receives the cooked gas-air composition from the blast burner.

Cast-iron equipment is more often produced with sectional heat exchangers and has blast or tubular burners. Boiler power is average, weight is much lower than fire tube boilers. The cast-iron heat exchanger serves for a long time subject to a certain temperature regime. For installation, the first and second type of boilers are supplied disassembled due to their considerable weight.

Floor units are selected if it is required to heat several separate buildings or a large room, even if the total heating area does not exceed 200 m2.

Wall

A suspended gas convection boiler is mounted on a vertical fence or a metal frame is welded for it. The heat exchanger is made of steel or copper; burners are often made of a tubular type. Wall-mounted equipment is compactly placed in the room, boilers go on sale with all the necessary elements and trim parts. The sales kit is a kind of boiler unit with remote control.

The wall-mounted version with an open camera is not often bought, although it costs less and does not depend on electricity supplies. Closed wall-mounted boilers acquire more often, popular models are compact, have an attractive appearance. Manufacturers apply advanced technologies, the equipment is equipped with modern electronic filling. This can be a disadvantage, because the electronics can not withstand power surges and depends on the mains.

Wall-mounted boilers are sensitive to energy quality. The fluid is heated in a small casing with thin-walled inner elements. Poor water in the system leads to sedimentation. Antifreeze also does not apply to all wall units, as there is an instruction in the technical passport.

Advantages and disadvantages

The advantage of a convection gas boiler is its simplicity and low cost. Used inexpensive materials, because no condensation or corrosion of the metal. In convectors there is the possibility of reducing the cost of the intake and removal of combustion products through the use of natural traction.

The inefficiency of convection gas units is combined with the advantages of:

- the equipment is available in wall and floor type;

- some models have a cast iron heat exchanger that lasts a long time;

- condensate formed during operation goes into the pipe and does not act on the insides;

- easy to install and repair;

- some models do not use electricity;

- works silently;

- on sale a large selection of dual-circuit and single-circuit options.

The minus is that the heating system is designed taking into account the temperature of the energy source at the outlet, which should not be less than + 57 ° C, otherwise liquid droplets appear on the stacks of the heat exchanger, furnace and chimney, which violate the integrity of the elements.

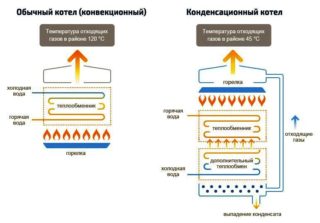

Comparison with condensing boiler

When operating condensation equipment, the water in the return circuit must be cooled as much as possible so that condensation appears. Drops fall from combustion products that are saturated with fumes. The coolant receives additional energy and raises the temperature until it enters the boiler heat exchanger.

When operating condensation equipment, the water in the return circuit must be cooled as much as possible so that condensation appears. Drops fall from combustion products that are saturated with fumes. The coolant receives additional energy and raises the temperature until it enters the boiler heat exchanger.

In condensation models there are additional heat exchange and condensation precipitation chambers, which are called economizers. The compartments are made of metal that is difficult to corrode, since the walls come in contact with the liquid. In convection units, heat is obtained only through the combustion of gas, and heat from condensation is not used.

Condensing units emit 20% more heat than traditional models when burning the same amount of fuel. The efficiency of the first type of equipment reaches 95 - 100%, and convection types show 82 - 86%.

Condensing boilers require a special line design in order to cool the energy source to a low temperature. Massive and expensive radiators are used, and if the liquid does not cool, the system with the unit will work with an efficiency lower than stated in the passport. Equipment is not available with open type furnaces.

Equipment selection

The boiler power is determined at the rate of 100 W per 1 m2 of the room. The indicator can grow up to 150 W, depending on the heating of neighboring rooms, the height of the ceilings and the area of window openings. The number is multiplied by the area of the room and the calculated power is obtained.

The type of ignition of the unit matters. Piezo ignition works by pressing a key and is independent of electricity. The lack of additional fuel consumption for a burning ignitor and the dependence on the flow of gas from the pipeline. An electric igniter is more economical, there are models that turn on automatically after a power outage.

Boilers of Korean manufacturers combine quality, reliability, low cost and adapt to gas pressure surges.The downside is the problems with finding spare parts for repairs, as well as the lack of service workshops.