Most owners of private homes when choosing a heating method prefer gas fuel. The decision in favor of blue fuel is explained by the fact that this type of energy carrier is among the most affordable and cheapest. The reliability of the operation of the equipment directly depends on such important elements as gas burners for heating boilers.

Design and principle of operation

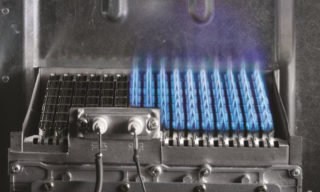

Complete combustion of gas and obtaining maximum thermal return are possible only if it is mixed with oxygen. A high-quality mixture during combustion forms a colorless torch with a blue tint, in the center of which the maximum temperature develops. It can be obtained only with a good burner, consisting of the following required elements:

- nozzle with ejector;

- firebox;

- flame control sensor;

- automatic temperature control unit.

The principle of operation of modern gas burners is that the fuel from the cylinder enters the nozzle, and then into the ejector. Due to the high feed rate, a vacuum forms in this place, which leads to an influx of air and its mixing with gas. Next, the resulting mixture through a system of tubes is discharged into the firebox, where it is ignited by an electric spark.

Types of burners

Boilers and burners are classified according to a number of signs:

- application area;

- type of fuel - liquefied and natural gas;

- developed working pressure and nozzle dimensions;

- type of fuel flow adjustment.

In accordance with the field of application, the burners are intended for installation in industrial and domestic boilers. The equipment of the first type uses injection burners with a supercharge from the built-in fan. Its declared power is in the range from 120 to 250 kW. For household models of heating units, this indicator does not exceed 120 kW. In these samples, atmospheric-type burners are mounted - without forced boost.

The difference between the burners is manifested in the developed working pressure, as well as in their nozzle sizes. In modern household structures, universal models are used that can work with various grades of gas. According to this criterion, diffusion-kinetic and injection samples of burners with partial or complete mixing of components are also distinguished. By the method of adjusting the torch, these devices are divided into the following types:

- single-stage single-mode;

- two-stage with two operating modes;

- with modulated adjustment.

Single-stage devices are automatically switched on if additional heating of the thermal medium is required, after reaching the desired temperature they are turned off. Two-stage burners are capable of functioning in 2 modes: at full power or only at a small fraction (40%). After the coolant reaches a fixed temperature, the gas valve closes, after which the burner continues to operate with reduced power.

Modulated devices operate in a wide range of capacities, varying from 10 to 100 percent.

Advantages and disadvantages

The advantages of nodes include:

- long terms of operation;

- silent ignition of the working mixture;

- complete utilization of combustion products;

- safety of use;

- automation of the control process of the ignition of the boiler.

The disadvantages of these mechanisms are considered in relation to their specific implementation. Specialized models of burners with a supercharged fan are characterized by increased noise, which forces the boiler to be installed in a separate room. Atmospheric analogues do not allow to obtain a high-quality mixture, which affects the efficiency of ignition.

Selection rules

When choosing the appropriate type of gas burner, the main attention is paid to its technical characteristics:

- nozzle dimensions;

- fuel supply method;

- a method of mixing gas with oxygen and controlling the composition of the mixture;

- compatibility with other boiler models;

- the presence of automation that controls the operation of the burner.

Among the noteworthy models, KChM brand products are widely used in modernized boiler units. They have three nozzles controlled by automation, and are usually installed in boilers of the circuit type.

When selecting a reliable and easy-to-maintain gas burner for heating boilers with automation, attention is also paid to the device for its ignition. The latter should occur without claps and similar extraneous sounds. The noise level of operation during ignition is noticeably affected by the design of the combustion chamber. In the process of assessing the reliability of the selected model, attention is drawn to the degree of safety of using the device.

Service Features

Gas burners, like other units operating at high temperatures, need regular maintenance and service. In accordance with current regulations, during the operation of gas equipment, any interference with its operation is prohibited, including for preventive purposes. This can be done only after stopping the current process and complete flame attenuation in the combustion chamber.

The procedure for preparing the system for maintenance:

- The gas main is closed, after which the boiler is disconnected from the power supply.

- The node is dismantled from its workplace.

- The nozzle is cleaned of deposits accumulated on the ignition electrodes.

- The working chamber is being cleaned.

If necessary, change the filter mounted on the gas valve.

Do it yourself

The burner manufacturing procedure is considered on the example of a solid fuel boiler unit. For self-assembly, a typical valve from an oxygen cylinder with the designation VK-74 is best suited. Work operations for its manufacture are carried out in the following sequence:

- The outlet pipe is being finalized by equipping it with a fitting for the connecting hose of the pellet boiler.

- On the mating part, connected to the gas cylinder, a nozzle mounted from an old blowtorch is mounted.

- A steel tube with a length of about 100 mm (with walls 2 mm thick) is welded to the cap with a pipe.

- A gap of 1.5 cm is left between the nozzle and the cap for oxygen access.

- For ease of installation, 3 wire guides that set the clearance value are first attached to the cap.

The result is a home-made burner, to which a suitable housing is selected, which allows it to be securely fixed. At the final stage, the resulting design is installed in the combustion chamber of the boiler.