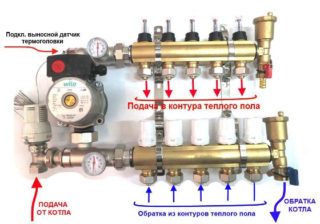

A mixing unit or collector for a warm floor is installed in order to regulate the circulation of the heat carrier and the level of its heating. In addition to the main function, this device helps to measure the pressure in the heating system, controls the correct supply of the heat carrier and eliminates excess air from the heating circuit. If warm water-type floors are installed in several rooms, you can not do without such a device. It is worthwhile to study the types of devices and the principles of their work in advance in order to make the right choice.

The principle of the collector for a warm floor

The mixing unit helps to realize the supply of thermal media without the need to connect to the common collector of the boiler room. A standard device of this type has a simple structure, is a group of several devices and can operate using a two-way or three-way type valve. If the heating system belongs to the mixed form, such a unit is supplemented by a circulation pump.

The second pump is needed to cover all the hinges of the flooring, while the first is responsible for the operation of the radiators. To determine the selection of the valve, you must first calculate the throughput for the circuits of the water floor heating and find out the temperature limits for the heat carrier. For the middle and southern strip, the lower limit is enough to 30 degrees or lower, for the north - from 35 degrees.

Circuit assembly

Two types of collectors work according to different schemes. A three-way valve combines two water flows: warm and cold, which come from a return pipe. It has a moving sector to control the intensity of the water flow. The part can be controlled using a thermal relay or a manual or electric thermostat. During operation, the heated water supply is connected to the valve openings with a return and the exit path for the manifold comb. Behind the valve, a pump is installed for pressure on water in the direction of the main comb, as well as a temperature probe. The device operates according to the standard algorithm:

- Heated water comes from the boiler and for the first time passes through the valve in an unchanged state.

- Information from the sensor about the temperature rises to the valve, which opens the mixing of chilled water.

- The system operates at this stage until the fluid temperature approaches the optimal value.

- The flow of cold water ends with a valve.

- The operation of the system continues until the water is heated to the limit temperature, after which the mixture is activated again.

The only minus of the three-way valve is that heated water can be supplied without mixing directly in case of failures. If polymer pipes are installed under a warm water floor, they may become unusable due to exposure to boiling water.

More reliable is the development of a two-way valve, during which water never enters the circuit directly from the boiler. This effect is achieved due to the balancing valve installed between each return and supply pipelines. He is responsible for the amount of chilled water and can change the value depending on the required temperature using a hex wrench. In the distribution unit, it is worth installing a controlled two-way valve with a temperature sensor.The intensity of the heated water supply will change if the sensor is installed after a pump capable of directing the heat carrier into the comb.

A distributor with a two-way valve mechanism is able to heat no more than 150-200 square meters. m of warm coating. Despite its reliability, it is characterized by low performance.

Collector types

Collectors are divided into several varieties depending on their price, set of functions and material of manufacture. The most expensive and reliable components are made of stainless steel. Brass collectors are included in the middle category, they are able to last a long time if made of a high-quality and durable alloy. Inexpensive devices are made of polypropylene, they are suitable only for low temperatures. The device itself externally represents a part of the pipe with the required number of bends, it can have simple or complex equipment.

- Brass

- Polypropylene

- Stainless steel

The list of common options includes collectors:

- with fittings for connecting circuits;

- with cranes of integrated type;

- with valves for regulating water.

There are budget options - assemblies of double valves: reverse and supply. Such devices may contain additional parts, such as a flowmeter, mounting holes, or taps.

How to make a choice

When choosing, first pay attention to the number of circuits required for connection. When buying a collector device for water flooring, it is better to purchase a comb with an additional margin for one output. It will be needed if there is a need to split a long circuit into two branches or connect additional equipment.

You also need to determine the type of material. The most reliable appliances are made of stainless steel, natural bronze or brass. The best option would be mixing units from well-known manufacturers: Valtec, Stout or Tim.

- Valtec

- Tim

- Stout

Self assembly device

The mounting scheme is most often already included in the kit of any collector device. You can assemble the collector for the warm floor yourself if you follow the step by step instructions. The device is mounted horizontally on a wall or in a pre-prepared niche, leaving free access to the main arrow of the heating pipes. Next, you will need to connect the collector to the boiler so that the heat carrier is supplied from the bottom, and the return goes along the top. After they install a check valve with a temperature limiter, a distribution comb is placed behind it.

Pipes passing inside the floor are fixed from above, coming from the heating system - from below. After installation, the device must be set according to the rules, check how tight all the connections are by connecting the collector group to the main pump. Using a pump, the pressure inside the system is pumped up, after which the water circuit must be left in this form for a day. If all the indicators are preserved, the installation was carried out according to the rules, the unit can be operated.

Connecting a heated floor to the collector device

Preliminary, they draw up a connection diagram indicating the dimensions of the pipes, places of their laying and connection with the heating components. It will be necessary to additionally calculate the throughput of the combs and select their diameter. It is important to choose the correct mounting location for the collector. It is better to give preference to a site to which there is always free access with a connection point that is located above other system elements.

Preliminary, they draw up a connection diagram indicating the dimensions of the pipes, places of their laying and connection with the heating components. It will be necessary to additionally calculate the throughput of the combs and select their diameter. It is important to choose the correct mounting location for the collector. It is better to give preference to a site to which there is always free access with a connection point that is located above other system elements.

Additionally, they put a protection system consisting of a bypass and an air valve at least at arm's length. After a full installation of the collector, all pipelines must be connected to it from a warm floor covering. Then check the tightness, quality, as well as the reliability of all joints.The first time to start the system is before the installation of the main coating begins, it is important to check the quality of heating for all highways, inspect the pipes for leaks. Only then do they begin to mount the topcoat.

In order for the appliance to work efficiently, it must be correctly configured taking into account the length of the circuit and the heating load. For this purpose, the valve is placed in a predetermined position by the circuit number and the number of revolutions.

Do you need a collector

The main disadvantage of the device is its high cost, but it must be taken into account that without it, warm water-type coatings will not be able to function normally. This is only possible if the coating consists of one heating circuit. In modern heated floors, the length of the pipes for laying can not exceed 70 meters. Since this amount will be enough only for 7 square meters of area, for a medium-sized room, at least three contours will be needed.

Most often, warm water-type coatings are installed in all rooms of an apartment or house. In this case, a mandatory installation of the collector will be required to evenly distribute the supply of thermal carrier. If we are talking about one small room, the collector can not be purchased. It must be remembered that without this device, the coolant will be supplied with temperature as in a common heating system. Also, without it, it is impossible to remove air jams and control the pressure.