To detect small cracks on the furnace wall, a regular visual inspection is performed. Ruptures that occur affect the life of the stove, through the slots a toxic burner enters the kitchen. Cracks are cleaned with a repair mixture, in the manufacture of which the recommended proportions of clay and sand are used to putty the furnace.

Causes of Cracks

Violation of the surface monolith occurs for various reasons, but the stovepipe error is the basis. Gaps in the wall do not appear if building materials are selected competently, taking into account technical characteristics and properties. The competence of the master, who lays the walls of the furnace, installs the internal elements and makes the pipe, matters.

The following factors influence the appearance of cracks:

- Long-term use of the stove in the winter. The plaster is torn due to the sharp heating of the cooled hearth.

- Haste when testing a newly laid out focus. Cracks form, because the material has not dried out or has not gained strength.

- Incorrectly performed masonry, in which, when heated, areas with temperature differences appear.

- Inconsistency of materials with the required thermal stretching. Failure to comply with the ratio of such parameters between mortar, brick and metal elements.

- Overheating of the focus. It uses fuel that produces more heat than the stove can withstand, such as coal for a wood hearth.

Before coating the stove with clay so that it does not crack, you need to find out the causes of the problem. Sometimes the furnace may crack due to a weak base or the use of materials with poor fire resistance. Sealing the joints in this case will not help, you will have to redo the masonry.

Repair is done immediately after detecting tears on the surface. The stove will smoke if you do not cover the cracks. You can prepare a solution for puttying the oven with your own hands or use ready-made refractory mixes from the store.

How to fix the problem

An option to solve the problem is to finish the outer plane with ceramic tiles. The material will last for a long time subject to technological recommendations.

Used types of tiles:

- porcelain tile;

- types of tiles;

- clinker material;

- terracotta.

To cover the stove so that it does not crack, you can use a clay solution. The mixture adheres well to the surface, and cracks rarely form.

The furnace plane is processed using tools:

- Putty knife. Several varieties are used for easy coating.

- Hammer for hammering nails under the plaster.

- Trowel. It is used for mixing the solution and applying the mass to the surface.

- Scissors for metal. The tool is needed to cut the metal plaster mesh.

- Grater. It is used for grouting the solution.

- Ironing. With the help of the device, the plane is leveled to the ideal state.

- Chisel. Used for notch in the area of the putty for better grip.

- Brushes. For wetting the surface.

- Construction level, plumb line. The tool is taken to align the plane in a horizontal or vertical position.

Clay coating of a brick stove in the country or in the house is available, the solution is kneaded without problems. Cracks need to be repaired by technology, wait for the previous layers to dry.

Plastering sequence

Before you cover up the stove or close up the problem areas of the stove, you need to study the sequence of work. The first time you can plaster, if the folded hearth stood for at least six months. There is a natural shrinkage and shrinkage of materials. Before starting work, the stove warms up so that the masonry expands. Kindling will prevent cracks after coating, when the hearth becomes cold. Plaster is not applied in frosty weather.

Further actions:

- Surface preparation is required before coating the brick oven in the house. The old coating is removed, the cracks expand and become deeper.

- A thin layer of liquid composition is applied to the aligned plane and left to solidify for 1 - 2 days.

- A steel mesh or fabric is fixed to the surface as a framework for reinforcing the layer. The mesh and fabric are wetted with a liquid clay solution.

- The mass with clay is applied in separate slots or smeared on the entire surface of the focus with two layers. The thickness of one layer is about 4 - 5 mm. An increase in size leads to instability of the plaster.

- The solution should dry, after which the surface is wiped with a grater.

- The finished surface is treated with liquid lime or painted with chalk composition.

If there is ceramic tile, it is removed from the oven. Elements can be glued again after the plaster layer has completely hardened.

Types of Putty for Ovens

The furnace belongs to the category of building structures that regularly change temperature, so the working mixture must meet the requirements put forward.

Mixtures for smears of furnaces are divided into types:

- simple formulations of two or more natural components;

- ready-made dry mixes for industrial production.

Materials for the solution are cleaned of related impurities, sand is passed through a sieve. Clay is rubbed through a frequent grate to separate small stones and roots.

Types of solutions:

- Lime. Take sand and lime dough in a concentration of (1 - 2): 1.

- Clay. Chamotte clay and quarry sand are used in a ratio of 1: (1 - 1.5).

- Lime-clay. It uses lime dough, clay, local sand in the cumulation of 0.2: 1: (3-5).

- Cement-clay. It takes cement, oily clay, quarry sand at a concentration of 1: 4: 12.

The first type is suitable for coating the plane near the firebox, because it does not withstand strong heating. Clay is suitable for sealing gaps and coating the first layer. Recycling is done with a solution of clay and slaked lime, which has some plasticity and prevents the appearance of gaps.

Cement-clay mortar is the most durable and is suitable for plastering foci that are very hot, for example, in a bath.

Clay solution

The material is suitable for smearing ovens, but its properties vary depending on the grade of the raw material. A preferred type is fireclay. For the solution, the same volume of components is taken, sometimes a little more sand is kneaded (for the initial layer). The plaster is mixed with greasy clay to increase adhesion. If you select too oily grades, the volume of sand increases.

The rule of mixing the solution:

- Clay is soaked in water for 5 days, followed by absorption. If the material is very wet, add liquids. It turns out a mixture similar to sour cream.

- Dry before kneading sand.

- Lime is introduced into the composition if it is necessary to increase adhesion to the surface. The component accelerates the setting and drying of the layer.

- Cement M400 is used for furnaces. With the addition of material, the solution sets after 20 - 25 minutes, and solidifies within 4 - 5 hours. The layer gains full strength after 2.5 - 3 days.

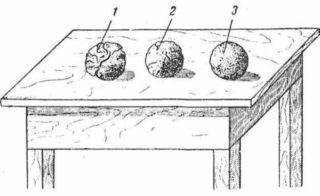

The solution is checked for cracking.Balls are molded from the pulp, dried and inspected. The material is suitable if no cracks appear on the samples. Testing is toughened for mixtures operating in harsh conditions, for example, at high temperatures. Dry samples are thrown from 1.5 m and inspect the surface for damage.

A wooden shovel serves as an indicator of the concentration of the mixture. If the solution adheres to the instrument while stirring, an addition of sand is required. Chopped straw, fiberglass or asbestos is added to the plaster. Reinforcing additives increase tensile strength. The furnace is finished with a solution, which includes natural components, so that with increasing temperature no toxic substances are released into the air.

Salt is sometimes added to the solution to increase ductility. Insects do not start in such a layer, which is important for private buildings. Gypsum in bulk contributes to a reduction in hardening time, but such a mixture is prepared in small portions in order to have time to work it out before drying.

Ready mixes

The industry produces powdered mixtures that contain the required ingredients. Materials sold are viscous and hard. There are on sale sealants with increased heat resistance and asbestos fiber for driving cracks.

The use of dry formulations:

- the bucket is filled with water;

- the volume of powder calculated according to the instructions is poured;

- a nozzle for an electric drill (mixer) is used to obtain a homogeneous composition without lumps;

- after the first stirring, the solution is left for 4-6 minutes and stirred a second time.

Powder mixtures set quickly after mixing with water, so they are used immediately and mixed in medium portions. The composition includes sand, clay, cement, additional components are introduced. The manufacturer guarantees the quality of the layer, if the work is carried out according to the technology.

Masonry compounds for plastering fireplaces, hearths and stoves contain plasticizing additives, therefore they work for a long time after drying. Finished powders are used to seal small cracks without removing the finish if the surface is tiled or with decorative types of bricks. The solution prevents the reappearance of cracks.

The ready-to-use mixture for application retains moisture well inside, therefore it does not require preliminary wetting of the wall surface. This position reduces the drying period of the furnace and saves working time. Layers are made thinner due to ductility, therefore material is retained.

The first firebox is allowed on the fourth day after the stroke. Facing is carried out one month after the active operation of the focus.

Metal furnace processing

Cracks in the steel furnace can be welded with the apparatus, but this version is not always appropriate at home. Ready putty is acquired or kneaded from certain ingredients.

Ready-made heat-resistant sealants are used in places where the body of the stove is heated to + 350 ° C (outer walls). They process cracks and spaced seams in metal products, seal pipes and penetrations through the roof.

The main component is silicone, but the properties vary with additives:

- More fire resistant include iron oxide, the paste is painted brown-red.

- Neutral compounds are used at the joints between metal and brick or concrete. When dried, moisture and alcohol are released from them, after which the seal of the crack receives the necessary tightness and strength.

- Acidic pastes emit acetic acid during the hardening process, therefore they are not used for metals, as cause corrosion.

Heat-resistant materials have good adhesion to the surface, they do not deteriorate from ultraviolet rays. Sealants do not crack after drying; they tolerate expansion and shrinkage of metal well at temperature extremes.The drying time for each species is prescribed on the package and ranges from several hours to a day.

On the surface of heat-resistant materials, paint does not linger, so they are selected according to the color of the base metal.