Tiles for facing stoves and fireplaces make it possible to give even the simplest design a unique look, to realize any design decision. The stove becomes an interior decoration, but at the same time its functionality does not deteriorate. Cladding tiles help retain heat much longer.

Oven tile coating requirements

Stoves and fireplaces in homes, saunas and saunas are constructions of increased danger. Therefore, their decoration and material properties are subject to special requirements. When choosing a product, first of all, you need to pay attention to heat resistance and strength, the color should be in second place.

Conventional ceramics are not suitable for facing the furnace. In the process of using the design, it will be subjected to high thermal effects. The main requirement for the facing material is its ability to withstand maximum temperatures. It is important to pay attention to the labeling of the package. The letter “T” should be on it, this indicates that the material is suitable for hot walls.

In addition to heat resistance, tiles must comply with the following requirements:

- be environmentally friendly - if the material contains toxic substances, when heated, they will be released into the air;

- possess the properties of heat capacity and heat permeability, so that the tile heats up faster and transfers heat to the room;

- to be waterproof, the required ratio of not more than 3%;

- have a high degree of strength and resistance to deformation.

High-quality tile does not contaminate hands, is easy to use on a daily basis, its external surface does not overheat, due to this, burns from touching are not formed.

Varieties of stove tiles

Depending on the design options and composition stands out a wide range of tiles for finishing the stove in the house.

Terracotta

This type of product is made of kaolin clay. The surface of the product has a porous structure. The top layer imitates a natural stone or brick. The main feature of this type is its high vapor permeability. Such material is used to finish the furnace in the bath and sauna. Terracotta tiles are produced in two versions:

- unglazed;

- glazed.

In the first case, a pigment is added to the production, which gives the clay a pleasant natural shade.

Terracotta is characterized by a long service life, high performance and a high degree of environmental friendliness, does not emit toxic substances when heated.

Majolica

View majolica is a product made of baked clay with a surface treated with glaze. Most often, a drawing is applied to it. All elements are made by hand, so the cost of such products is very high.

Majolica is characterized by highly porous texture. Due to the glazed surface, it cannot be used in rooms with a high level of humidity. Thanks to the thinnest layer of glaze, the tile does not crack when heated.

The positive characteristics of this type include:

- durability;

- brightness of colors;

- resistance to temperature extremes;

- simple maintenance.

A variety of color options for tiles will allow you to choose it for any interior.

Tile

To give a decorative effect, the portal of fireplaces is faced with ordinary ceramic tiles. If the combustion device is built into the wall, the decoration can be done with traditional glazed ceramics. For the oven, it is best to use a tile with a matte finish, as the glaze may crack over time due to heating. Laying should be done on a special heat-resistant adhesive.

Brick tile

This type of finishing material has a high degree of durability. Clinker tiles are made of various types of clay, it is designed for finishing hot walls. The disadvantage of this option is the color. Products are made only in terracotta shades.

It is not recommended to use such material for finishing structures with internal brick walls.

Clinker is most often used in rooms with significant temperature jumps, as it is characterized by a high degree of frost resistance.

Tiles

Tiles for this type of oven are suitable for any finish due to meeting all the necessary characteristics. It is an environmentally friendly material.

Fireclay tiles

This type of product is made of refractory clay with the addition of stone flour. The main advantage of fireclay tiles is its acid resistance. It can be overlaid with gas-fueled structures. The material does not crack, is resistant to temperature extremes, withstands high static overloads, shockproof.

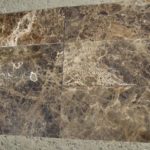

Porcelain Tiles

Heat-resistant tile for facing the fireplace and stove, made of granite and marble chips and several types of clay, is called porcelain tile. The material is characterized by a non-porous texture, resistance to temperature changes, low water absorption, a wide range of colors.

Marble

Natural marble allows you to create a very stylish interior, but it has a big minus - high cost. In this regard, it is used infrequently. Finishing a fireplace or stove with marble is best entrusted to professionals who can make invisible seams.

Fake diamond

This type of tile is produced in two versions: with smooth and torn edges. The second option is great for beginners. Thanks to the torn edges, the seams will be almost invisible. Imitation of stone allows you to create an original interior in the house.

- Marble

- Fake diamond

- Porcelain Tiles

Tile marking

Stove has its own marking, which should be affixed to each pack. This is necessary on the basis of European and state standards. Marking is an alphanumeric combination that displays material properties. The sort of tile is indicated by color and number:

- I is blue;

- II - red;

- III - green.

The package also indicates the caliber from "0" to "5" mm, this is the industrial size of the product. Here, deviations can occur that arise due to firing, which causes a violation of the geometry.

The letter "T" indicates a heat-resistant indicator. The numbers 1 and 2 indicate the number of firing. The symbol “E” indicates the percentage of moisture absorption. The larger this number, the more moisture the material can absorb. This indicator for stovetops should not exceed 3%.

Sizes and colors

For convenient work with stove stoves, it is recommended to choose small products. The optimal tile size is 25 * 25 cm with a thickness of not more than 8 mm. These dimensions will help to create the necessary thermal conductivity and strength of the cladding.

Larger tiles can be made to order, but it will be difficult to sheathe the structure. Due to its own weight, it can quickly collapse.

The color of the tiles for the stove is selected depending on the overall interior and material:

- A wide variety of shades gives natural marble. Due to the fact that the stone contains many impurities, it can be even the most unusual colors. In nature, you can find black, green, blue, red and moon marble.

- If the finish is granite, the choice can be made of brown, black and gray.

Most options appear when using ceramic tiles. Clinker also offers a wide variety of shades.

Cladding selection

In the design of the facing tiles for furnaces, never meet geometric ornaments, but there are complex patterns in almost every form.

- Plant patterns that are characteristic of tiles and majolica. They are appropriate in any style, from classic to modern.

- For a classic interior, it is best to opt for porcelain stoneware; it allows you to create real paintings, realize the most daring design decisions.

- Plain products with minimal decor are perfect for a modern interior.

- Material under a natural stone is best suited for a country house.

The interior of the village house will be effectively decorated with tiles in the style of Khokhloma or with the image of plant elements.

For elite country houses, granite or malachite tiles are perfect. A Russian stove is best done with ceramics. Tiles and majolica will look attractive.

When choosing it is important to focus on the size of the room. For example, a material that is too large will not look good with a small village house. Natural stone or porcelain stoneware can effectively emphasize the fundamental nature and power of a high fireplace in a large cottage.

You need to purchase tiles with a margin in case if in the process a part is broken.

Styling features

Facing the stove in a bathhouse or in a house is a complex process, but if certain rules are followed, everyone can handle them. In order for the lining to be durable, you must adhere to the following order:

- To prepare the old walls, remove the layer of plaster, clean the joints between the bricks.

- Primer the surface. To process the brick, you need to use a mixture of primers with fine marble chips.

- A metal mesh is pulled onto the primed surface.

- The machine is plastered, then carefully leveled.

- The tile is laid on a layer of glue with a thickness of not more than 1 cm. The glue should be applied to the entire surface so that there are no voids.

Do not heat the stove until the glue has completely dried. Otherwise, the tile begins to lag behind the surface.

Each stage of the cladding needs time to dry:

- for a primer layer for 2-3 hours;

- Plaster on average takes two days.

After laying the tiles you need to wait at least a month, only then melt. During this period, the solution will become as strong as possible. It is important that during drying in the room the temperature does not fall below +5 and does not rise above +25 degrees.