Brick lining of a bathhouse made of iron is an event that most lovers spend tastefully and beautifully steam up. This is justified not only by improving the appearance of this product, but also by increasing the level of its performance. To overlay an iron stove in a bath with a brick, you can invite professional craftsmen, but it will cost a round sum. It is better to do it yourself, and put the saved money on the purchase of building material. To achieve a good result, you need to choose the right brick and follow the step by step instructions for its laying.

Benefits of using a metal stove in a bathhouse

Metal furnaces are very popular due to the numerous advantages compared to analogues from other materials.

Iron foci are distinguished by the following advantages:

- Affordable cost. Thanks to the established production technology, the manufacture of products is carried out in a semi-automatic mode with minimal human participation.

- Simplicity and speed of installation. If you even have basic metal skills, you can make a furnace yourself.

- Thoughtful and efficient design. When developing various models, such nuances as the configuration of the furnace, air supply, removal of combustion products and adjustment of the flame intensity are taken into account.

- Fast heating. Iron has excellent thermal conductivity. Energy is not wasted, but spent on heating the body of the product.

- Profitability. The firebox uses a little fuel compared to classic models. Products with an overhead blower are able to work at one gas station for up to 10 hours.

- Universality. Steel stoves with cast-iron grates are capable of burning firewood, briquettes, pellets and even coal.

- Compactness. This quality is important for small-sized steam rooms where every centimeter counts.

However, the iron hearth also has some drawbacks that contribute to the decision to brick the iron stove in the bathhouse.

Why brick the steam room oven

Despite the fact that modern products look beautiful and representative, in the interior of the steam room against the background of natural wood, they will look inorganic. And this is not the only reason to brick the stove in the bathhouse.

The following factors speak in favor of the event:

- The outer surface of the metal is very hot. This leads to overheating of the room and the creation of an uncomfortable atmosphere in it.

- Risk of fire. If you overdo it with fuel, the heat from the boiler becomes so strong that it can begin to smolder from it, and then the steam room finish burns.

- Chance of burns if accidentally touched. In the case of bricks, this risk is eliminated, since this material absorbs heat, evenly distributing it throughout the volume.

- Iron quickly heats up and also cools quickly. Because of this, it is difficult to control the temperature in the room.

- Corrosion protection. Sooner or later, the protective coating comes off the iron and the boiler begins to rust. This is not aesthetic and is fraught with thinning of the walls of the furnace body in the future.

- The integrity of the interior. Brick on a wood background looks much better than metal.

The disadvantages of the metal heater are non-critical, but they do not allow you to make the rest in the steam room comfortable, pleasant and healthy. The brick lining of a sauna stove with an external firebox helps to solve the problem.

Methods for lining the stove in the bath

The hearth in the furnace process is heated to a high temperature, which is accompanied by its thermal expansion. All this must be taken into account when choosing a facing material and the method of its application. In this case, it is necessary to plan the decoration of not only the walls, but also the pipes.

The furnace can be coated with the following materials:

- Plain red baked clay brick. It is better to choose full-bodied blocks that conduct well and keep heat longer.

- Monolithic ceramic brick. Excellent material, characterized by average thermal conductivity, strength and resistance to sudden temperature drops.

- Fireclay refractory stone. It is used for laying the firebox, it absorbs heat well, and therefore, is not suitable for external decoration.

There are such options for encircling the focus, regardless of its location:

- Continuous cladding. This is the easiest way to finish the boiler. It is similar to laying tiles on the floor and walls of the premises. Only here has its own nuances. The first is the right choice of cladding. It is necessary to take tiles that are resistant to high temperature and have the same coefficient of thermal expansion as metal. Another condition is the preparation of a solution with the desired composition. A mixture of clay, sand and cement is best suited. Seams must be rubbed with a special waterproof grout.

- Thermal screen. This design is a blank brick wall, laid out at a distance of 2-3 cm from the outer surface of the boiler. The advantages of this design is that the heat is transferred to the stone, which ensures good heating of the room, while preventing the likelihood of fire and burns. In addition, the lack of contact between metal and brick eliminates the appearance of cracks during uneven thermal expansion of materials.

- Facing convector with vents. Such designs are used for facing foci of high power, which is developed by pyrolysis plants or boilers of long burning. A vertical wall in half a brick is laid out 4-5 cm from the furnace. At the bottom and top, air is left through which air circulates under the influence of differences in altitude and air temperature. Such a system works efficiently, evenly distributing heat throughout the steam room.

- Thermal screen

- Continuous cladding

- Convector lining

The choice of technology is based on the size of the steam room, its configuration, the type of fuel used and the estimated time of the bathing procedures. The thinner the brick layer, the faster it will heat up. But a thick layer of cladding keeps heat longer in the case of accidental or forced interruptions in the loading of fuel.

Step-by-step instruction

Brick building a boiler is a sequential event that begins with planning. First you need to choose a stove. You should consider where it will stand in order to most effectively heat the steam room. The most common option is the center of the wall farthest from the entrance with the furnace moving out. Sometimes a hearth is placed in a corner, with shelves around it. If the room is large, the best choice is to install a large round boiler in the middle.

It is necessary to calculate the construction materials and the need for tools.

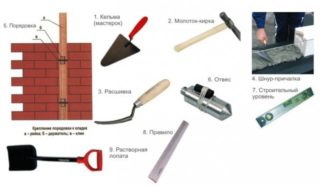

To work, you will need:

- mixer for mixing the solution;

- level, tape measure;

- shovel, trowel, trowel, steel spatula, rubber spatula;

- thermal plaster;

- facing brick;

- adhesive mixture;

- grout for joints;

- container for kneading;

- respirator, goggles and gloves.

Since the construction involves the use of solutions, a positive temperature inside the sauna is required.

Foundation

The boiler can be placed directly on the floor of the steam room if it is a reinforced concrete slab or thick boards on powerful logs with supports.If these conditions are not met, it is necessary to equip the foundation. It must be done separately, not tied to a tape structure or piles. The base plate for the boiler should be 10-15 cm larger on each side.

The work should be done in the following sequence:

- Mark out taking into account the perimeter of the boiler.

- Dismantle the outbreak, if installed earlier.

- Make supports for logs if the floor is wooden.

- Dig a pit under a concrete base up to 40 cm deep.

- Pour a layer of crushed stone and sand in a pit 20 cm high, spill the mixture with water and level it.

- Make a frame of reinforcement, install it on plastic supports with a size of 5 cm.

- Knead a solution of cement, sand and gravel in a ratio of 1: 3: 3.

- Pour concrete by removing air bubbles from it with a steel bar or factory vibrator. Level the surface with a spatula.

The foundation must last at least 21 days to gain strength. Wet the surface daily with water to prevent cracks.

The basis for the furnace

After the screed hardens, the following work is carried out:

- It checks its level and evenness.

- If there is a serious difference in elevation, it is eliminated by a brick fastened with cement mortar.

- A sheet of steel 5-6 mm thick is laid on the masonry. So that he does not budge, it is secured with pins or anchor bolts.

- The base is cleaned of rust, treated with an anti-corrosion compound and coated with paint.

- The device is installed in its place, a chimney is connected to it, the joint of the pipe and the boiler is sealed.

Before carrying out further work, the boiler is covered with polyethylene so as not to stain it with a building mixture.

Solution preparation

The problematic issue is the risk of cracking in the solution and its detachment from the base. Despite the fact that it will not heat up much, a special recipe is required, the basis of which is clay. This material is more ductile than cement, and better tolerates heat.

Ready mixes are sold in hardware stores. Given the specifics of the question, it can be quite difficult to find them, so it makes sense to prepare the solution yourself. Some components can be found for free.

The following ingredients are used to make the mixture;

- river sand;

- red clay;

- tile glue;

- plasticizers.

Cooking sequence:

- Sift sand through a sieve to remove large inclusions. Rinse it in order to clean it from the ground and biological impurities.

- Place the clay in a container, pour it with an equal volume of clean water. Stir material periodically, kneading lumps.

- Add sand to the tank and mix thoroughly. Add plasticizers.

- Immediately before use, pour the adhesive mixture in a volume of 10-15% of the base.

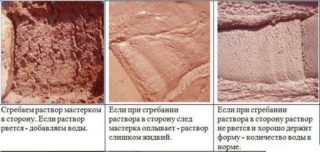

A properly prepared composition should consistency resemble homemade sour cream. If it is too thick, you need to add water, dry sand is added to the liquid solution.

Brick preparation for cladding

Before laying the bricks around the boiler, you need to carry out the following actions with them:

- Check for evenness of faces, correspondence of length, height and thickness, absence of cracks and chips. The rejected products are useful for filling the remaining openings in the rows.

- Dip the stones in water for 5-6 hours, so that the material gains moisture. During the masonry, they will not take water from the solution, thereby not weakening its astringent properties.

You need to remove the bricks from the tank 30-40 minutes before the start of work, so that the water from the glass is dry, the surface is dry.

Furnace lining

Laying is carried out in the following order:

- Waterproofing is laid on the base.

- From one of the corners, the first row is laid out before the completion and filling of the voids.

- All subsequent levels are done with a half brick ligation.

- Every 2 rows, steel bars are laid.

- Masonry is checked by level after each row.

- Excess solution is removed immediately to a depth of 10 mm.

- The lower vents are made in the second row, and the upper ones in the penultimate.

- The seams are overwritten.

- The holes for the furnace and the blower are reinforced with steel corners.

Masonry should be carried out in two stages, so that the first part of the wall has strengthened and sank.

Before the test firebox, the finish should dry for 3-4 days. After that, you need to warm it up, burning branches, paper and other material that produces a small amount of heat. After another day, you can melt the boiler with 2-3 logs, constantly tossing them for 4 hours. After that, the furnace is ready for operation.