Water supply to the house, regardless of the source of water supply, is always done by laying an underground pipeline, which usually freezes on especially cold winter days. Moreover, its deepening into the soil does not always give a positive effect. Therefore, many owners of personal sites are thinking about ways to insulate a water pipe in the ground at a shallow depth.

Why do you need insulation

The main reasons for the need to insulate water pipes above and below ground in a private house:

- In the absence of a special insulation pipe freeze, and underground they have to be laid very deep (up to 2.5 meters), which is associated with high labor costs. When taking water from a well, one has to face the same problems.

- The water carrier protected from the cold is more effective since it does not need additional heating. Thanks to this, it is possible to reduce energy costs (electricity, in particular).

To prevent freezing, pipe communications are also insulated at the sections of the exit from the well and at the places of entry into the residential building.

Warming Methods

There are several methods known to effectively insulate the water mains supplied to the house. Some of them are used not only in everyday life, but also in production, where pipeline insulation is equally important.

The use of thermal insulation materials

For the stated purposes, conventional heaters are widely used, used to solve typical problems, including insulation of building structures. These include the following types of thermal insulation materials:

- Styrofoam;

- polyurethane foam;

- mineral wool;

- sprayed heaters.

- Sprayed PPU

- Polyurethane foil

- Styrofoam

- Mineral wool

Most of them allow you to reliably isolate the water supply from contact with soil, freezing in winter to a considerable depth.

Electric heating and continuous flow effect

An electric cable with an alternating current passed through its shell is a common method that guarantees the insulation of water pipes in a private house. Self-heating cable products are operated in automatic mode and guarantee a minimum of energy costs for heating. This effect is achieved through built-in automation, due to which energy consumption increases only after the soil temperature drops below a certain point. Electric cables are well protected from moisture, which allows them to be laid directly in water pipes.

An electric cable with an alternating current passed through its shell is a common method that guarantees the insulation of water pipes in a private house. Self-heating cable products are operated in automatic mode and guarantee a minimum of energy costs for heating. This effect is achieved through built-in automation, due to which energy consumption increases only after the soil temperature drops below a certain point. Electric cables are well protected from moisture, which allows them to be laid directly in water pipes.

The essence of heating by the continuous flow method is that fast-moving water does not have time to freeze. If the house has regular water consumption or artificially organized water circulation in a closed circuit, they will not allow freezing of the pipeline in the winter.

Heated by air and high pressure

This method is technically difficult to implement and is used only in public utilities or in industry. The water supply is placed in a shell of large diameter pipes, and heated air enters the gap between them. In everyday life, a simplified scheme is used in which the insulation of HDPE pipes is carried out by placing them in pipelines of a larger diameter. The air gap formed between them is used as a kind of insulator.

The idea of heating with high pressure refers more to fiction than to reality. To increase the temperature by 1 degree, it will be necessary to increase the pressure by 132 atmospheres, which is physically impossible for a water supply system with an indicator of 5 atm.

Insulation Requirements

For insulation of water pipes in the ground at a shallow depth, typical thermal insulation materials are used that meet the following criteria:

- low thermal conductivity;

- water resistance;

- resistance to chemically active environments;

- temperature resistance;

- durability and wear resistance.

Fulfillment of all these requirements will extend the life of the pipelines and not spend additional funds on updating heating systems.

Thermal insulation materials and their features

It is most convenient to protect the insulated heating pipes for laying in the ground with a shell that matches the shape of their surface. Most samples of insulation materials for pipes are produced in the form of cases having built-in channels for laying a heating cable. A rigid foam shell is the best option for thermal insulation of pipelines laid underground. Polyfoam does not pass and does not absorb moisture and, moreover, is very cheap.

Another material suitable for these purposes - polyurethane foam - is resistant to chemical and biological influences and does not deteriorate in the presence of mold, microbes and other microorganisms. The shell or shell made on its basis is lightweight and can be mounted without assistance. Shells based on foamed polyethylene are widely used for thermal insulation of pipes laid on the street. In addition, they can be used to seal open sections of pipe routes located in the caisson well.

Mineral wool is not bad for the stated purposes, but it is easily crumpled, after which it loses its thermal insulation properties and begins to absorb moisture. Therefore, it is usually used to warm the outer sections of the water supply.

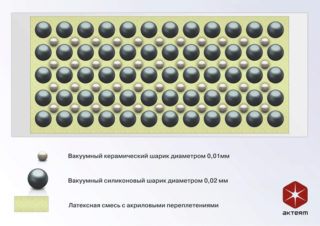

Heat-insulating paints are considered a high-tech product that is applied to the insulated surface with a brush or spray in several layers. They are ideal for protecting pipelines and processing containers of various types and purposes.

In industry, there are frequent cases of using liquid polyurethane or polystyrene applied to the pipe shell by means of a spray gun to protect the insulated surfaces. Due to the high cost, this technology is practically not used in everyday life.

Do-it-yourself water pipe insulation

Before you insulate the pipes for water under the ground, you need to decide which option of thermal insulation will cost the least. Most often they focus on the use of inexpensive foam or PPP shells with a high density of material.

Insulation at a shallow depth

The procedure for warming the water supply in the country or in a private house is considered on the example of a foam shell. Self-installation of the shell on the pipeline from HDPE is not complicated and is carried out in the following sequence:

- The foam sheath is worn on the pipes slightly raised from the trench.

- The locks on it snap into place, each successive segment is shifted by about a third of the total length.

- The insulation elements are fixed with tape or special plastic ties.

- At the end of the work, the pipeline is lowered into the trench on an already prepared sand cushion.

At the final stage of the measures, the trench is covered with the selected soil, and then it is closed with the turf laid aside.