Warming of the exterior walls of the apartment is an effective measure that allows you to create comfortable conditions and a healthy microclimate in your home. It often happens that central heating does not cope with the task assigned to it. You can get out of this situation by installing your own boiler or additional electric heaters. Both methods are not original and practical, are not always possible in technical terms and require large investments. Warming an apartment from the outside is much cheaper, requires a one-time investment and is not particularly difficult. The main thing here is to choose the right material and monitor compliance with the repair technology.

Do walls insulate from the inside

If you look at this method from a purely practical point of view, then it will seem simple and attractive in all respects.

The pros seem so powerful that they are hard to resist:

- there is no need to look for industrial climbers and adjust their work schedule for them;

- wall insulation in the apartment from the inside can be done with your own hands, since this process is simple in execution;

- the availability of constant access to the insulating structure, which makes it possible to carry out current repairs and replace damaged fragments;

- the presence of freedom in choosing the type and thickness of heat insulators, which is appreciated by the owners, whose facades of rooms overlook the central streets of the city.

However, the decision to insulate the wall in the apartment from the inside in a panel house is not optimal for many reasons. Property owners may regret their acceptance over time. In order not to get into an unpleasant situation, you need to familiarize yourself with the negative consequences of this method.

Disadvantages of insulating the building from the inside

The internal insulation of apartments has disadvantages that can not be ignored:

- Reduced usable space. The material itself has a certain thickness, and it still needs to be covered with drywall, requiring additional finishing.

- The need to move furniture. In some cases, when the walls are made to individual sizes, you have to perform their costly fit or order a new set.

- For the period of work, you need to move out of the apartment so as not to breathe polluted and moist air. Sometimes it may be necessary to take things that are sensitive to dampness.

- The geometry of the heating system is broken. Pipes and radiators do not heat the rooms so efficiently, even when the temperature in them is high.

- Pollution of air and interior items by-products of repair - mortar, glue, dust, small fibers. Conducting a long and time-consuming general cleaning. There is a high probability of irreparable damage to some objects and surfaces.

The main disadvantage of the internal version is that the supporting walls are constantly exposed to the environment. Due to the temperature difference, concrete panels crack, the brickwork loses its solidity. Condensation accumulating under the heater leads to the formation of mold, which gradually corrodes and penetrates into the rooms.

The advantages of external insulation

Owners of corner apartments are well aware of the potential for cold winters and extreme hot summers. It is impossible to warm the housing in extreme cold, and in the sun it is difficult to cool it even with air conditioning.

Covering the end wall with a heat insulator gives these advantages:

- Usable space is saved. This is true for owners of small housing, where every centimeter of area and volume counts.

- There is no need to move furniture, to endure anything that could suffer during the repair.

- External insulation performs not only an insulating function. The material covers all cracks and cracks, protecting the room from moisture during precipitation.

- All work is carried out outside, inside is clean and calm. The owners do not think where they will temporarily move and how long they will have to put things in order.

- The walls are protected from adverse weather factors and maintain a stable state. All this contributes to the extension of their service life and preservation of operational characteristics.

The main thing in this method is that heat losses will be much reduced, and dampness will not penetrate inside.

Material selection

On the trading floors there is a wide selection of wall insulation for the apartment. Materials vary in performance, thermal conductivity, installation methods and price ranges. Cold buildings should be insulated with insulators that are best suited to the characteristics of the buildings. Wall materials, climatic conditions and building architecture should be considered. Last but not least, you should focus on the price so that after a few years you do not have to repeat the repair.

Mineral wool

Mineral wool is made of natural stone, steelmaking slag and glass battle. Finished products go on sale in the form of mats and rolls. The thickness of the products is 50-400 mm with a width of up to 100 cm. The material is flexible, elastic, elastic and low thermal conductivity.

A feature of the product is its hygroscopicity. From moisture saturation, it loses its insulating properties. During the installation, it is necessary to seal the mineral wool with a mortar. Another nuance is the allocation during installation of the smallest volatile fibers. Protective equipment for hands, eyes and breathing is needed.

Expanded polystyrene

Polyfoam is a good choice for external insulation. It is produced in the form of plates with a size of 100 × 100 mm, a thickness of 50 and 100 mm. It is a lot of balls welded together with a porous structure. Plates are characterized by low specific gravity, low thermal conductivity, moisture resistance and brittleness. The decision of manufacturers to extrude polystyrene foam contributed to the improvement of its performance. Plates gained elasticity, flexibility and extra strength. Locks around the edges provide seamless bonding in the masonry. An important factor is the price of products, which is lower than that of commercially available analogues.

Polyurethane foam

The insulation is a liquid substance, which, after application to the surface, foams, multiplies in volume and solidifies. The finished coating is characterized by low thermal conductivity, strength and durability. Foam has excellent adhesion and adheres to any plane, penetrating into the smallest gaps and filling all voids.

The sprayed substance can be used as an independent finish or together with the frame, which is covered with decorative cladding. The disadvantage of PPU is the high cost of the process and the need to invite specialists with special equipment.

One of the effective modern heaters is foil foam. The material is available in the form of long strips twisted into a roll. After gluing to the walls, it is covered with a finishing cladding. The plus is that the insulation can be used to finish cold walls inside and out.Ecowool has proven itself not bad, but it requires careful waterproofing.

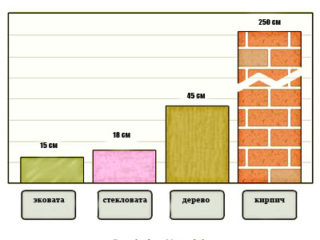

Insulation thickness

The calculation of the required thickness of the insulation is carried out by multiplying its thermal conductivity coefficient by a regional indicator.

So for Moscow, the optimal choice is the following numbers:

- mineral wool - 150 mm;

- polyurethane foam - 100 mm;

- polystyrene - 100 mm;

- polystyrene foam - 100 mm;

- penoplex - 100 mm.

When decorating houses, heat insulators can be combined, applying them to the features of architecture and wall materials.

Options for wall insulation in the apartment

For concrete panels, it is better to use polystyrene, which is put on glue and fastened with plate dowels. Then the surface is covered with reinforcing mesh, plaster and covered with acrylic paint.

It is advisable to carry out wall insulation in a brick house with polyurethane foam or basalt cotton wool. In the first version, the foam is applied to the surface, after which it is left as is or closed with decorative panels.

If the wall is cold, cover it on both sides using thick coatings on the outside and thin coatings on the inside. For external decoration, you can use inexpensive polystyrene 10 cm, and in the room to cover the surface with a decorative cork, simultaneously performing the function of decoration.

If there is mold on the wall, you must get rid of it mechanically before starting work. After this, the constructions should be treated with an antiseptic and the remaining recesses should be repaired with a solution. To prevent this phenomenon in the future, you need to trim the wall from the outside with a vapor-permeable insulation, which will remove moisture from it.

When installing a ventilated facade, wool is placed in a frame, which is closed on both sides by a membrane sheet. Such a pie provides protection of the supporting structure from temperature and air circulation, which removes moisture released from the building.