The special masonry of cylindrical furnace heating devices can significantly reduce the consumption of bricks and the weight of the entire installation. The construction of such a modification is not considered costly, but the device itself cannot be attributed to highly efficient, economical. It is not recommended to install such a stove in a residential building. It is suitable only for the summer version of the kitchen, cottage.

The device of a circular furnace in a metal case

Any stove is placed on a reinforced base. Its brick part consists of the following elements:

- Volumetric firebox for laying wood. Since such a stove requires a lot of fuel, with a large firebox, you can not often throw firewood.

- Vertical chimneys. Usually there are three, sometimes up to five. The design of a stove with a 1 helical chimney is also acceptable. Due to the increased number of the latter, the heating device will have greater efficiency.

- Chimney.

A cylindrical brick body is put on a casing of steel sheets. Subsequently, a small iron cylinder is obtained, which does not take up much space. It can be placed in room walls or in the middle of the room.

Advantages and disadvantages

The main advantages of the heater in a metal casing:

- Simplicity of the device - can be assembled on your own.

- High fire safety. If the walls of the stove are damaged, the metal case will not allow the spread of sparks beyond the boundaries of the structure.

- Great heat capacity. Due to the specifics of the device, the heat from the combustion of fuel is fully used for space heating.

- The small sizes. This allows you to place it in any part of the house.

- Affordable price.

- The ability to decorate at your discretion.

The convenience of the stove significantly exceeds its few disadvantages:

- Great heat output from thin stove walls. All surfaces of the structure must be lined with heat-resistant material.

- Significant fuel consumption. Such a stove requires a third more firewood than an ordinary Russian. For this reason, it is installed for the purpose of occasional use.

If a round brick furnace will be built in a wooden house, the nearest walls must be protected from possible fire with metal sheets. It is impossible that there are furniture elements, flammable objects near the heating device.

Building materials and tools

To erect a stove, you must first purchase the following list of tools:

- level;

- roulette wheel;

- a grinder with a diamond wheel;

- Master OK;

- bucket;

- hammer.

It is also required to purchase construction and consumables:

- brick;

- cement;

- sand;

- waterproofing material (for example, roofing material);

- metal sheets for arranging the case or another type of lining;

- valve;

- grate;

- 2 doors.

In the case of independent manufacture of the casing, metal scissors, a welding unit or a rivet gun are also useful.

Procedure

First you need to build a solid foundation. If it was not previously provided, the masonry must begin with the dismantling of the floor. The prepared place is neatly marked under the foundation.

The order of work when installing the foundation:

- Lay the sand cushion in the base. It is necessary to use a level so that the horizontal surface is smooth. Otherwise, the stove will be crooked.

- Prepare a solution of fine sand, cement in a ratio of 3: 1 and pour the base.

- Put a reinforcing mesh, cover with a prepared solution on top.

- Cover the wet surface with a layer of roofing material (for the purpose of waterproofing) and sprinkle with a layer of sand (2-3 cm).

Next, you need to prepare a clay solution: sifted sand, water, clay. The latter should be wet, otherwise it should first be irrigated with liquid.

- Mix clay with fine sand in the same ratio.

- To the resulting mixture add water in a ratio of 6: 1.

Stir the resulting mixture thoroughly.

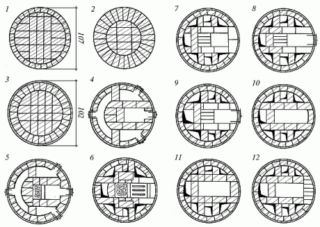

Furnace order:

- 1 row. horizontally lay bricks on the sand (flat), then pour cement mortar on top, level it.

- 2, 3 row. In both rows, the bricks are laid by analogy with the first. At this level, plumb lines are launched on the sides, so that subsequently the stove does not deviate to the side.

- 4, 5 row. 4th row - the basis of the hole for ash. The walls of the ashpit are laid out of brick edge. On one of them with a soft wire should attach a small door. To ensure tightness, heat-resistant material is wound around the last at the borders. You can use an asbestos cord.

- 6, 7, 8 row. With the help of masonry, part of the ash pan is blocked, on top of which the grate is laid.

- 9-13 row. A firebox is being built (the brick is laid on the edge). A door is mounted on the side of the entrance to the ash pan.

- 14, 15 row. It is necessary to block the firebox with a brick, leave an opening for smoke behind.

- 16, 17 row. A neat hole is made for future cleaning of the chimney, which must be laid with knock-out bricks.

- 18-26 row. Lay out reverse channels. The required number of the latter (from three to five), as well as the configuration will be determined by individual needs.

- 27 row. All channels should be blocked with masonry, but in the last place you need to leave the chimney opening.

- 29, 30 row. A chimney is formed, a valve is attached to maintain traction.

Based on the actual ceiling height in the room, the number of rows of the future stove can be increased or decreased.

You cannot use a round stove without installing a chimney. You can determine its appearance at will. But at the same time, you must remember the mandatory rules:

- Provide thermal insulation of the chimney in case of contact with the walls of the house.

- Observe basic fire safety requirements.

- During the construction of the pipe, add a small volume of cement to the solution so that it is resistant to strong winds and frequent rains.

- A metal coating is required on top.

A round furnace in a metal case is a reliable and simple heating system for irregular use in suburban buildings where it is impossible to install a conventional boiler heating system. Folding it is not easy, but it is quite possible, if you follow the order, correctly prepare the solution.