The heat-insulated floor in the bathroom allows you to heat the room qualitatively and evenly and make your stay comfortable and safe. It is better to equip this system at the stage of building a house or overhauling an apartment. If this was not possible, there are several ways to reconstruct the bathroom with your own hands. To make the right decision and avoid annoying mistakes, you should familiarize yourself with the types, features of heating equipment, the rules for its installation and operation.

Is it possible to make underfloor heating in the bathroom

The room is characterized by increased dampness, the presence of steam and the constant ingress of water on the floor. There is always a risk of failure of valves, clogged sewers and flooding of neighbors from below. Conditions are not the most optimal, but not critical.

In favor of the fact that the bathroom can be equipped with heating elements, the following arguments testify:

- Sockets are located at a sufficient distance from taps, floors and spray guns to eliminate the slightest chance of a short circuit.

- Floor slabs have great strength and resistance to deformation. Communications laid under the outer lining will not be subjected to mechanical stress.

- Modern insulating materials provide complete tightness of the joints between the panels and the bearing surfaces themselves. Even in case of a breakthrough, flooding of the lower levels will not be.

- The structures used for laying have high reliability and a long service life. They maintain good condition throughout the entire life of the building. Subject to installation and operating procedures, you will not have to carry out laborious repairs to replace heating elements.

SNiP does not prohibit the installation of floor heating systems in apartment buildings. The only caveat is the need for coordination when connecting to central heating.

Advantages and disadvantages

Like any design, a warm floor has its positive and negative sides. Thanks to the use of modern technologies, the technical characteristics of products are improved, their reliability and safety levels are increased.

Pluses of constructions:

- Optimum distribution of warm air. It is formed at zero level, rises up and fills the entire volume of the room. Due to this, the same temperature is achieved at all points of the room.

- Lack of protruding parts, as is the case with radiators and coils. If necessary, controls are masked in niches or carried out.

- The comfort of staying in the bathroom. The legs of a person rest on a warm base, there are no unpleasant sensations and the likelihood of diseases from hypothermia. Hot floor eliminates the formation of mold and fungus.

- Easy installation. You can do the installation yourself, using the minimum number of special tools.

The design also has disadvantages, they are as follows:

- The inevitability of raising the floor level to accommodate heating elements. Depending on the type of product, this figure is 2-10 cm. In some cases, it is necessary to increase the threshold of the door to even it with the finish lining.

- Lack of access for inspection, maintenance and repair.Products are poured with cement screed or tile glue. After that, they become an integral part of the monolithic slab.

- The need to install reflectors so that the heat goes up, and not to the ceiling of the neighbors below.

- Additional costs when using electrical products. Power consumption is 150-200 W / m². Even for a small bathroom of 3 m², 14 kW will be consumed per day, and 420 kW per month. With modern electricity tariffs, the comfort fee may be too high.

You can choose the best option for arranging a bathroom after familiarizing yourself with the characteristics and features of the heating systems on sale.

Options for underfloor heating for the bathroom

By the type of conductor used, the underfloor heating in the bathroom under the tile is divided into 2 categories - water and electric. The selection criteria are determined by such factors as the form of ownership of the property, type of heating, the presence of a constant supply of hot water to the heated towel rail. A private building can be equipped with any system, while for repairs in the apartment of a municipal building there are some restrictions.

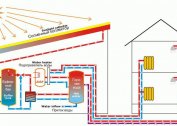

Water floor

Owners of apartments on the upper floors need to know that the installation of such structures is allowed only at the first levels of the building. This is due to the fact that the screed and pipes filled with water create a critical load on the walls of the building. In addition, the probability of a breakthrough of highways and flooding of the lower floors is taken into account.

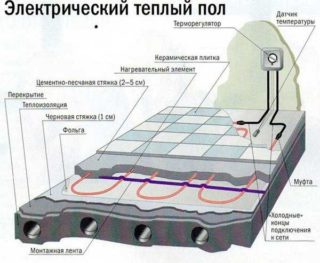

Water structures consist of several parts, each of which performs a specific function:

- Waterproofing. Prevents leaks during communication interruptions and condensate delay when heating ceases.

- Conductors. Represent special flexible pipes. Products are distinguished by strong walls, good thermal conductivity and low coefficient of thermal expansion. The laying pattern can be spiral or snake.

- Reflective screen. Serves to direct heat in the right direction (so as not to heat a thick slab).

- Cement strainer. It takes into its array the released energy and evenly distributes it on the surface. Performs the task of fixing the pipes and protecting them from external damage.

- Collector. It is intended for distribution of hot water on contours.

- Finishing Ceramic and stone tiles are used, characterized by a low rate of heat transfer resistance.

If the system is connected to central heating, an additional mixer is installed to reduce the surface temperature to the optimum. The degree of heating is regulated by hand by turning the taps.

Electric floor

Installation and operation of these structures is not accompanied by such risks and difficulties that are inherent in water counterparts. For installation, there is no need to obtain permission from the management company and coordinate their actions with someone in the house.

For heating floors in bathrooms, you can use the following heating elements:

- Heating cables. Consist of a metal core and well-conductive polymer insulation. The thickness of various models varies between 5-16 mm. Installation is carried out on a pre-prepared frame, after which it is poured with cement mortar. The step between the rows is determined based on the degree of heating and the area of the room.

- Heating mats. They are thin heating wires rigidly fixed to a plastic mesh. Available in the form of strips equipped with terminals for connecting products to a single network. For laying, there is no need to raise the level of the base and fill the screed. It is allowed to use an adhesive composition 3-4 mm thick, on which the tile is laid.

- Infrared film. This is an innovative material with a minimum thickness and high efficiency.Given its high cost and fragility, it is advisable to equip with a film a wooden floor, plates trimmed with waterproof laminate, varnished parquet or an engineering board from KDP. Keep in mind that the glue practically does not stick to the smooth surface of the film.

When deciding which material to choose for insulation, you need to objectively evaluate all factors, eliminate risks and correlate price, quality and upcoming costs.

How to install

The installation procedure at the initial stages is the same for all types of systems, regardless of the characteristics of the building and the selected coolant.

Installation should be carried out in the following sequence:

- Remove old coating, remove debris.

- Clear holes and cracks. Fill them with sealant or tile adhesive.

- Level the surface with a gypsum screed so as not to overload the plate.

- Lay the insulation material on the base. Depending on the characteristics of the room, tiled foam or roll foil foamed foam is used. Seal joints with aluminum tape.

- Fix the waterproofing sheet. The strips are laid with an overlap of 15 cm, the ends are displayed on the walls by 20-25 cm. The joints are also glued.

- Fix the damper tape around the perimeter of the walls to compensate for the thermal expansion of the coating.

It is better to lay the water pipeline in special foam blocks, in which there are already recesses of the desired configuration. After laying the pipes, the excess is cut off and the ends are fastened to the manifold pipes. Then it must be connected to a heated towel rail. To do this, it is made of metal fittings through passage. At the entrance, a ball valve is installed, which can turn off the water supply when it is not necessary or when leaking. Then the screed is poured and the tile is laid.

The cable is laid on a fixed metal mesh, to which is attached a wire or plastic ties. Then the mixture is poured and the tile is applied.

Heating mats can be immediately glued to waterproofing; mechanical fasteners are not required. After setting the glue, the floor is tiled.

The final stage of installation of any system is to check its operability. It is necessary to identify signs of leaks or short circuits using instruments. Structures can only be used after the screed or glue has completely hardened.

Common mistakes

When arranging a water floor, inexperienced masters make such mistakes:

- The use of steel pipes for the water system. Right angles inhibit the flow of water, the metal rusts, compounds begin to leak over time.

- The use of a spiral circuit over a large area. This leads to uneven heating and a cold surface in the last third of the return line.

- Ignoring the installation of the collector, thermostat, mixer and faucet. The result is uneven heating of the base, the creation of extremely high temperatures and the inability to control the system.

A competent choice of materials and compliance with construction technology are the key to creating an effective and safe warm floor.