Various materials are used to warm houses. One of the most popular is considered building glass wool insulation. This is a material, which is a compressed plate, which is obtained from thin long melted fibers of glass, sand, lime and dolomite.

Glass wool properties

Glass wool insulation has a number of properties for which it has become widespread and in demand. Among them, the following can be noted:

- High density. It is formed as a result of twisting the fibers among themselves into peculiar cocoons. This ensures thermal insulation and impermeability of cold air.

- It absorbs noise that can come from humans, animals, cars.

- Fireproof material. The composition contains binder resins, but they do not belong to the group of combustible and spontaneously combustible substances.

- Resistance to external influences: chemical, biological and mechanical. Glass fiber insulation does not lose shape and size even after prolonged use, it does not bite the mouse, it does not appear fungus.

These characteristics make glass wool a popular material for warming rooms.

Types of glass wool

Glass wool is classified by the method of manufacture and use.

According to the manufacturing method

It is made by two methods: continuous production and staple. It is packaged in different forms: rolls, mats, shells.

By application

Steklovata is available in various options depending on the application. The same factor affects the main properties: thermal insulation, sound insulation, elasticity.

- For horizontal masonry (for example, insulation of a glassy floor).

- For external or internal use.

- For pitched roofs.

- To fill the gaps.

When choosing a form of packaging insulation, you should focus on the scope of its application

Material advantages

Glass wool is a very flexible material that adheres tightly to planes. It has high strength and vibration resistance.

At high temperatures, the material does not emit harmful toxic substances that adversely affect the human body. Over the years, does not lose its qualities.

The material is light, and very little debris remains during operation.

Wall insulation methods

For siding stitching

It is better to insulate the walls of the house with mats. First, the surface is leveled and dried. Then a waterproofing film is attached to it. On top of it, bars of 5x5 are packed. The interval between them should be 1 cm less than the width of the cotton wool, due to this, a tight fit of the material to the wall is achieved.

It is necessary to consistently lay the mats in the direction from the bottom up. They are attached to the wall with special dowels. From above, a layer of film is again laid, which is glued at the joints and attached to the bars. At the end, the wall is sutured.

For plaster

Pre-prepare the wall: clean and primer. A frame is made, which is attached to it. Proceed to the distribution of cotton wool: it is attached in a checkerboard pattern using special polymer-cement glue. After two to three days, dowels are used for additional fastening. Then the glass wool is glued and plastered.The wall is primed, after which it is already possible to proceed to the decorative finish.

Roof insulation

Roof insulation is a very important part, since about 30% of the heat is lost due to it. First you need to do waterproofing. At the same time, it should be attached with a slight overhang, without stretching. Nails are driven into the rafters with an interval of 40 cm: they will hold the cotton wool until the work is completed. After the insulation is laid, and on top is the metal profile, which is then covered with a waterproofing film. In the end, everything is sewn up with prepared material.

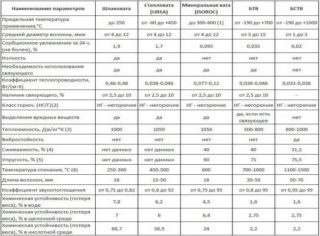

Mineral wool or glass wool

Warming of the house is an important issue on which the coziness and comfort of the stay depend. The most common materials are stone insulator and glass wool.

The difference between mineral wool and glass wool is expressed in the following components:

- Strength and resilience. The thickness of the mineral wool is from 2 to 10 microns. In the second material, this number varies from 3 to 15 microns. At the same time, fiberglass-based insulation is approximately 3-4 times shorter in length. This is insignificant, but affects the density and elasticity of products.

- Resistance to temperatures. The maximum temperature of the first is up to 700 ° C, and the second is up to 450 ° C.

- Convenience in work. Using basalt-based material is safer than fiberglass. The latter are sharp, so they can cause minor damage to the skin.

- Price. Mineral wool is usually more expensive. At the same time, it is not difficult to purchase material - it can be found in the public domain.

Which is better: glass wool or basalt cotton wool, everyone decides for himself, focusing on distinctive features. Both materials cope well with the main task - warming the rooms.