The boiler can be connected independently at home. The method of installation of equipment depends on the use of the appropriate type of raw material and the selected heating system.

Varieties of heating systems

For the correct connection of the unit, it is necessary to study the main varieties of heating systems.

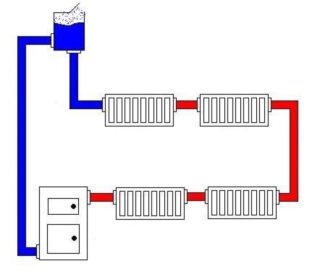

Open type

Such systems have a fairly simple scheme. Consist of an expansion tank, pipes, boiler and radiator. The basis is an expansion tank that stores excess water when it is heated.

The system does not use a pump. The tank is not completely tight, which leads to the evaporation of water and the need to replenish its level. The fluid in the pipes circulates slowly, so the pipes should be warmed up gradually during operation.

If the system does not work in the winter, the water is drained so that the pipes do not freeze. The boiler is installed in low places at home, and the expansion tank at high elevations. Installation requires few parts and fasteners.

Closed type

Closed type heating systems are hermetic, therefore water evaporation is excluded, circulation is carried out using a pump. The scheme includes pipes, radiators, a boiler, an expansion tank and a pump.

The principle of operation is based on the opening of the expansion tank valve with increasing temperature and eliminating excess coolant. After the degree of heating decreases, the pump pumps the excess liquid back into the pipes.

The system maintains pressure within strictly defined limits.

Mounting diagrams

The installation diagrams of heating batteries are represented by 5 connection methods:

- the upper option involves the supply or discharge of fluid only from the top of the radiator;

- the lower connection method is characterized by the flow of liquid directly from the connector located below;

- one-sided inlet is carried out through the top, and its outlet from the bottom only on one side of the pipe;

- Diagonal connection is carried out when warm water is supplied from above and diverted from below, but already from the back of the battery;

- The spot scheme is used infrequently, since its implementation requires a special radiator - installation of the input and output of the coolant from 4 corners in the battery.

The connection of the system is carried out only after a preliminary calculation of all the characteristics ensuring the normal operation of the unit.

How to connect units

The connection process depends on the type of boiler using a certain type of raw material for heating the house: natural gas, electricity, solid fuel).

Installation of gas boilers

Boilers using gas as raw materials are a profitable option for private ownership. Units must be selected taking into account certain factors:

- price and manufacturer;

- amount of power consumed;

- number of circuits;

- principle of eyeliner (floor or wall);

- method for cleaning waste materials.

Gas installations are equipped with a burner, expansion tank, pump, pressure gauge, thermometer, heat exchanger, exhaust gas exhaust system.

You need to connect the gas boiler in a separate room with a chimney and in-line ventilation.

Tools required:

- apparatus for welding;

- drill with a set of drills;

- screwdrivers;

- scissors for cutting metal products;

- building level;

- black marker, tape measure.

The procedure is carried out on a prepared level ground. For safety reasons, a sheet of iron is placed on the surface. Pre-connect the chimney and check the draft.

The unit is connected to a common heating system. On the reverse side of the pipeline mount a special protective filter from blockage. The water pipe insert is made as close to the entrance to the room as possible.

Water pipes should be equipped with shut-off valves (valves) for dismantling without draining the water.

The installation of gas equipment is coordinated with the relevant supervisory authorities and checked by a qualified specialist.

Connection of solid fuel devices

Solid fuel boilers are most often installed in residential buildings where there is no access to the gas pipeline. Raw materials for them are coal and firewood. In terms of design, they resemble furnaces equipped with modern facilities and meeting all the necessary requirements.

The boiler room for these units should have well plastered walls, ventilation and a protective coating.

The boiler is mounted horizontally on a flat surface. The height of the foundation is 15 cm above the base, the space for the furnace of raw materials is at least 50 cm.

Tools required:

- ball valve with a diameter of 50 mm 2 pieces;

- driving 2 pieces;

- safety valve;

- pressure regulator (manometer);

- automatic air exhaust;

- ball valve 15 mm (diameter) 2 pieces;

- steel coupling (diameter 50 mm) 3 pieces;

- bends (57 * 3.5 mm);

- transitions (57 * 32 mm) having a wall of 3 mm;

- chimney with a slide gate valve;

- pipe (57 * 3.5 mm);

- temperature resistant sealant;

- special winding;

- circulation pump.

Procedure execution algorithm:

- installation of the unit directly on the foundation;

- connecting heating pipes using faucets, special winding;

- grounding and electrical connection;

- installation of a security system (pressure adjustment, air vent, protective valve);

- assembly of the chimney and sealing of the joints with a sealant;

- filling batteries with water;

- checking the location of the necessary elements (damper, grate);

- first bookmark firewood.

Installation of electric boilers

The main advantage of electric boilers is the absence of combustion products during their operation. But this type of heating is expensive, since the electricity consumption for a private house is quite high.

Varieties of boilers are classified by type of heating:

- heating elements - the presence of a container with distilled water or an antifreeze liquid based on ethylene glycol;

- induction - units operating on the basis of electromagnetic induction;

- electrode - heating water having a certain concentration of salts with the creation of resistance.

The connection of these units does not require a chimney and the permission of special authorities. The scheme involves the installation of temperature sensors in the pipeline, radiators, drain, shut-off valves, expansion tank and circulation pump.

For normal operation, a voltage stabilizer is required. During installation, it is important to completely isolate the water supply, as a short circuit and fire safety breach in the house may occur.

Safety measures are mandatory (installation of a circuit breaker, grounding). The cable is mounted in the cable channel, the equipment is closed with a special casing. The boiler must be well fixed to the foundation.

Double boiler circuit

When connecting a double-circuit boiler, you must pay attention to the device of this unit. Two circuits work independently of each other, provide heat and hot water in the house.

Two heat exchangers (primary and secondary) simultaneously heat water for heating and domestic use. The double-circuit boiler connection scheme requires the availability of agreed documentation from the gas service.

Necessary tools for connecting a double-circuit gas boiler to the heating system:

- level, brackets, dowels and screws for mounting the unit;

- plug-in connection DN15 "American" in a half inch;

- ball valves, соединение inch American connector;

- overhangs, nuts, fittings (tee, coupling, elbow);

- sealing threads, paste, tow, fum tape;

- filter for rough water purification with a magnet to protect the heat exchanger from salt buildup;

- circuit breaker type 2A, cable or socket for connecting to the mains;

- pipes for the circuit and installation of the chimney;

- a set of additional tools: keys, screwdrivers, hacksaw, cutting device, drill, file.

The most suitable place for connecting the unit is a separate room that meets the established standards. Wall-mounted installations can be mounted even in living rooms.

When connecting a wall-mounted boiler, load-bearing walls are used, floor units are best installed on a non-combustible base (concrete, clay or metal). The device must be freely available. The room provides good air circulation.

Installation steps:

- fixing the device with the help of an assembly template, bracket, screws and dowels;

- wall protection with non-combustible materials (basalt cardboard, minerite, asbestos, roofing steel);

- marking the place for the chimney and equipment installation;

- when installing the unit use only ball valves with the use of plug-in connections "American", which in the future will allow you to remove the boiler without any difficulty;

- determination of the length of pipes for connecting the boiler to the system, threading, strapping, collecting all the necessary details;

- installation of a filter for rough water purification;

- installation of shut-off valves at the exit of the boiler;

- installation of a shut-off valve on a pipe that supplies hot water;

- connecting the unit to the mains (installation of a 2A circuit breaker or equipment of an individual outlet with a cable through a circuit breaker);

- installation of the chimney.

The boiler should be located as close as possible to the gas pipeline and connected through pipes for safe operation. After performing all the above procedures, the following points must be observed:

- obtaining technical specifications and relevant permits, design documents (unit diagram, located communications);

- calling a gas specialist and connecting the boiler to a common main;

- obtaining permission for further operation of the device.

Connecting boilers to start heating systems has its own characteristics, which must be taken into account before directly implementing the procedure. In most cases, help and consultation of specialists is needed.