The design of underfloor heating has its own characteristics, taking into account which they can not be installed in every room. Experts do not recommend additionally insulating floors from massive boards and natural parquet, but a warm floor under the laminate can be a modern and more profitable solution. Installation of such material requires special skills and is distinguished by its nuances, which are worth knowing in advance, especially to those who plan to do home repairs on their own.

Is it possible to lay a warm floor under the laminate

Even the most modern heaters are not able to make the laminate more pleasant and warm to the touch. Its surface is not made of wood, it is a dense layer of resin that prevents premature wear and abrasion. Since it remains cool even in the hot season, a good option is to install a warm base under it, which will improve the natural properties of this practical material.

Laying a warm floor under the laminate requires special attention, since this material is not combined with all heating systems. This is a building material with a high wood content and to some extent possesses its properties: it absorbs moisture and swells from its excess, dries up or deforms in case of temperature increase. A high percentage of resins in its composition softens the negative properties of the tree, nevertheless, it should be selected especially carefully before laying on a warm base.

Surface preparation

Before laying an electric or standard underfloor heating under the laminate, it is worth assessing the degree of wear of the old coating. If it is not able to perform its functions, it is dismantled, with an acceptable state, thorough cleaning of dirt and dust will be enough. It is also worth considering the permissible norms of height difference, which must correspond to a film height of 3 mm, so as not to make a mistake, you can use the level.

Places in the room where the equipment or furniture will stand can not be insulated, but if desired, the coating is made insulated around the entire perimeter. Power always depends on the area of the room that is heated, the larger it is, the lower the level of its consumption. When choosing the appropriate type, the calculations are carried out independently or with the help of a specialist who can calculate the optimal level and choose the right option for the thermostat.

It is necessary to lay the laminate on a flat surface, in the presence of irregularities they are eliminated and then dried with a vacuum cleaner. After these measures, you can begin to install any type of coating.

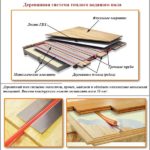

Wood base

Wood and planks are less problematic than concrete screeds. Old boards in Soviet-built houses should be removed before laying the heating system if they do not meet the standards of operation. A wooden base can be laid in a few days, and not in two weeks, which must be allocated when installing concrete. After such a replacement, the new floor will be perfectly flat without various negative consequences of unnecessary savings.

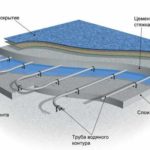

Concrete base

Concrete screed is considered more reliable than wood, so most heating systems are installed on such a foundation. Concrete allows you to make a warm floor as strong and reliable as possible; a screed of this type is used in new and secondary multi-storey buildings, as well as in a number of private buildings.Of the minuses, it is worth noting the additional time during installation - concrete needs at least two weeks to harden in the right position.

- Wood base

- Concrete base

Warm substrate

The heated floor must be reliably protected from moisture and other influences, therefore, before laying the laminate on the base, it is necessary to put a special film substrate according to standard technology. The best choice would be waterproofing and a thermal insulation layer designed to prevent losses from downward radiation, which helps to significantly reduce energy consumption and increase the efficiency of the entire system.

You can use any type of insulation, but for a laminate, a foam level material with a thickness of at least 3 mm is best. It can be reflective or cork, its effectiveness does not decrease depending on the type, but when installing floors it is important to take into account the thickness of such a material. The most popular option is made from Dacron, it is more reliable compared to the foil coating, which is not suitable for infrared floors.

Heat loss can be reduced by sticking joints on substrates with adhesive tape with special metal spraying. This item will be useful to anyone who plans to install underfloor heating at home.

Mounting technology

At the initial stage, preparatory work is carried out, the room is completely vacated, furniture and other items are taken out of it. The old material is removed if necessary, or simply leveled, replaced with a wooden screed with a concrete screed or left, if permitted by safety standards, the type of building and particular room.

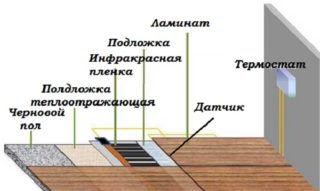

It is necessary to decide in advance which floor to lay in the room, it can be infrared or water. The thermal insulation kit for electrical coating under the laminate is selected on the basis of reflective or foil materials, it is prepared taking into account the size of the room and put the right side up, connecting the stripes with standard tape. The infrared film is laid on the entire surface in whole or in part, retreating from the walls 10 cm from m. It can not be overlapped.

The connection of the thermostat requires special attention and is carried out according to the instructions:

- Choose a convenient place to connect, which should be located near the wiring.

- The wires are laid parallel to the film and fixed with pliers in the areas where the copper streaks of the film are located.

- All joints must pass the insulation procedure, for reliability, the ends of the copper conductors are filled with silicone sealant.

- The temperature regulator is connected inside or outside, in the first case, a recess is made in the wall, in the second case a special plastic box is hung on the wall.

- The temperature controller is connected and activated, then you need to wait a few minutes and check the segments in different places for the degree of heating.

- The film is grounded with a foil type adhesive tape, connecting its ends with a wire, for additional protection against damage, you can use a polyvinyl film.

In the process of work, it is important to observe safety precautions and take into account the operational standards of materials. This will help prevent emergencies and minimize their risk.

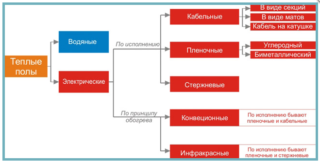

Varieties of underfloor heating

Not all floors with a heating system can be successfully combined with a laminate. There are three types of coatings that are used with this material: electric, infrared or film, and water. All options are suitable for installing the coating both indoors and on the balcony or porch. It is best to give preference to options from well-known companies and brands that produce materials taking into account the characteristics of the laminate.

Infrared

The infrared floor is based on the effect of infrared radiation and is called film, because it looks like a very thin film, supplemented by strips of material that conducts current. It is considered the most suitable option, since its installation does not require the use of glue and screed. Also, the IR version is quite economical and ideal for heating coatings with a low level of thermal conductivity. This floor is safe for health and does not harm the laminate by maintaining heating at a certain level.

Electric

This type is considered the most popular, but not well suited specifically for the laminate. When laying the floor under the laminate, it is necessary to lay a substrate that has low heat transfer and further reduces the heating efficiency. In order for it to uniformly heat up, you need to wait at least an hour, which requires large amounts of electricity.

Water

The water-type coating is mounted on the basis of a cable piping system hidden at the bottom and connected to central heating. It is advisable to install such floors in private houses, since in multi-apartment buildings pipe laying above other rooms is not allowed according to safety standards. The water version is quite expensive in terms of maintenance and installation, its repair also requires large material costs.

Using a temperature controller

The thermostat or thermostat is necessary to control the temperature and is responsible for the main tasks in the operation of the coating with heating and taking into account the plus and minus values. The device sets the base temperature level, programs the frequency of heating, and also controls the on and off time of the entire system.

Thermostats are fixed at the optimal level, most often at a height of at least 20 cm. This allows the device to work more efficiently, which ultimately helps to stabilize the entire floor system with a laminate floor.