Warming under siding is a practical and effective way to reduce heating costs and improve the appearance of the building. This technology can also be considered as restoration of the facade of the building, when its repair for some reason is impossible or associated with unreasonably high costs. Insulation of a house for siding can be carried out at the stage of its construction or after some time, when this becomes necessary. In order to properly conduct wall insulation for siding, you should familiarize yourself with the features of this process, the rules for choosing and installing heat-insulating material.

Criteria for choosing a insulation for siding

When choosing a heater for the walls of a house outside for siding, one should be guided by a number of criteria, on which the quality of the final result will depend immediately upon completion of work and in the long term.

Insulation for siding for external use is evaluated by the following indicators:

- Coefficient of thermal conductivity. Determines the ability of a material to transfer thermal energy through itself. In construction, indicated by the letter λ, measured in W / (m² × ° K). The lower this indicator, the higher the insulation qualities of the insulation.

- Water absorption. Indicates the property of a material to absorb water and retain it in its mass. Measured as a percentage of the volume of a substance relative to absorbed moisture. When wet, the weight of the insulation increases, the thermal conductivity decreases.

- Vapor permeability. It characterizes the property of a substance to pass vapor with equal pressure on both sides. The indicator is measured in mg / (m² × h × Pa) and is taken into account when siding is insulated with structures made of wood, aerated concrete and other materials that also have ventilation qualities. For buildings made of concrete, iron and plastic is not taken into account, since the listed substances are vapor tight.

- Fire hazard. Indicates the ability of the material to ignite and maintain the combustion process. Flammability indicators are evaluated as G1-5, non-combustible compositions are marked with NG.

- Density. Indicates the amount of mass per unit volume of insulation, measured in kg / m³. In the calculations, it is taken into account as the load on the bearing surface.

- Mechanical strength. It characterizes the ability of a substance to maintain integrity under vertical pressure, tension and twisting. Since the insulation for siding is not subjected to any loads, this indicator is not taken into account in this technology.

- Biological inertness. Indicates the resistance of the material to the development of fungus and mold in it, as well as the unattractiveness of animals and insects.

- Ecological cleanliness. An indicator of the absence or volume of substances harmful to the environment that the material emits.

An important criterion for choosing a heater for a country house is its durability. It is necessary to dwell on products, the service life is 50 years or more.

Types of insulation

Choosing a heater for the walls of a wooden house outside for siding, it is better to dwell on time-tested materials from reliable manufacturers.

There are such types of thermal insulation:

- Blowing. Ecowool and polyurethane foam belong to this category. Substances are applied to the surface with a spray gun, but this is where their similarity ends. Ecowool is made from cellulose, after solidification it remains in the same volume as it was when applied.In this case, the substance has high vapor permeability and low thermal conductivity. With polyurethane foam, everything is different. It is served on the wall in the form of a liquid, and then foams and quickly solidifies. The material has excellent insulating properties, but absolutely does not let steam through.

- Mineral wool. This class includes slabs and rolls made of glass, metallurgical slag and volcanic rocks. The thickness of the insulation varies between 10-20 cm with a width of 60 cm and a length of 120 cm. The most popular in the construction of mineral wool is Knauf, Rockwool, Isover and Technonikol. A high level of hygroscopicity is combined with good vapor permeability. Given these properties of the material, it is necessary to isolate it with a membrane fabric. The canvas provides free passage of steam without delay in the mat. Mineral wool is used for warming houses made of wood, brick and aerated concrete.

- Based on polystyrene foam. Polyfoam is the most popular and common material, both in private and in professional construction. The industry produces polystyrene foam in the form of plates with a thickness of 2-20 cm, a width of 60 cm and 100 cm, and a length of 100 cm and 120 cm. Manufacturing technology is divided into pellet pressing and extrusion. In the first case, a layer of closed balls is obtained, and in the second, a porous substance with open cells. The most popular products of the brands Penoplex, Styrex, TechnoNIKOL, Primaplex, characterized by high performance. Considering the combustibility of expanded polystyrene, it is not used in open form. Plastering is applied, which leads to a rise in the cost of the structure.

To choose the right material for insulation, you need to take into account the composition of the walls, climate, rainfall and your own capabilities. Priority on prices is not worth doing, as they are not always a measure of quality.

Advantages and disadvantages

You should familiarize yourself with the technical characteristics of the materials, their positive and negative properties. A mistake in planning can lead to big trouble in the near future after the construction is completed.

Advantages of mineral wool:

- low thermal conductivity;

- elasticity;

- excellent sound insulation;

- ecological cleanliness;

- durability;

- ease of installation.

Disadvantages:

- hygroscopicity, insulation needs additional decoration;

- shrinkage under its own weight;

- emission of volatile fibers during installation.

Advantages of expanded polystyrene:

- ease;

- water tightness;

- strength and hardness;

- long term of operation.

Disadvantages:

- use without protection is impossible;

- UV degradation;

- fragility;

- flammability;

- lack of soundproofing properties;

- the material does not pass steam.

Advantages of sprayed materials:

- speed of application;

- filling all cracks, cavities, including hard-to-reach ones;

- low thermal conductivity;

- biological stability.

Disadvantages:

- flammability;

- high cost of equipment or services of professionals.

Choosing an external insulation, you should analyze all its characteristics and only then make a decision.

Installation of insulation for siding

Installation of insulated siding is not particularly difficult and can be done with your own hands, without involving assistants.

To work, you will need:

- puncher, grinder, screwdriver;

- hammer;

- level, tape measure, square;

- stapler;

- scissors;

- hacksaw;

- steel profile;

- insulation;

- siding.

A common mistake by masters is the use of black iron hardware. Over time, they are completely destroyed by corrosion. Galvanized or stainless steel fasteners should be used.

Warming the house should be in the following sequence:

- Prepare the base. Remove lighting fixtures, plates, wiring, telecommunication cables, platbands from the walls. To clear the basis from a brick, foam concrete block, concrete of flows and unstable fragments. Carry out a surface treatment with an antiseptic and a deep penetration primer.

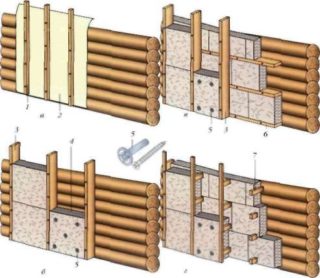

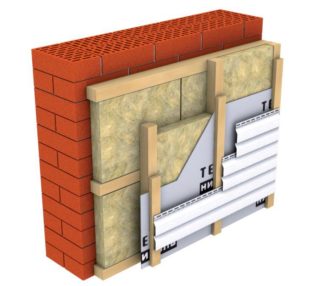

- Make a crate. The material may be a wooden beam or steel profile. The distance between the vertical fragments of the frame is taken equal to the width of the solid slabs and is 1-1.5 cm less than the fragments of mineral wool. To process a crate from decay and corrosion.

- Carry out the installation of insulation. Expanded polystyrene is glued and then fixed on the wall with plate-shaped dowels. The remaining slots are blown with foam. Mineral wool is inserted into the frame completely and is held in it due to the strength of elasticity. Additional fastening is not required. Foam is applied between fragments of the frame, the excess is cut off after solidification.

- Install a windproof foam film or a membrane sheet for porous insulation.

The final step is to strengthen the siding. It is recommended to place the panels horizontally to prevent water from flowing under the finish.

Technology Examples

The choice of the method of laying the material is made based on the composition of the substrate, the thickness and configuration of the insulation.

In private construction, the following options are possible:

- Single-layer laying in the cell frame. It is used in the decoration of buildings made of foam concrete, brick and wood, the walls of which themselves have good thermal insulation.

- Two-layer laying. It is used in cold climates and for warming buildings with thin walls. To place the material, a cross grating is made, into which plates and mats are staggered.

- Frameless option. It is used when warming the structure with polystyrene foam or polyurethane foam. Only the siding frame is attached to the walls and insulation is already fastened between them.

Before deciding on methods of insulation, it is recommended to consult with specialists.